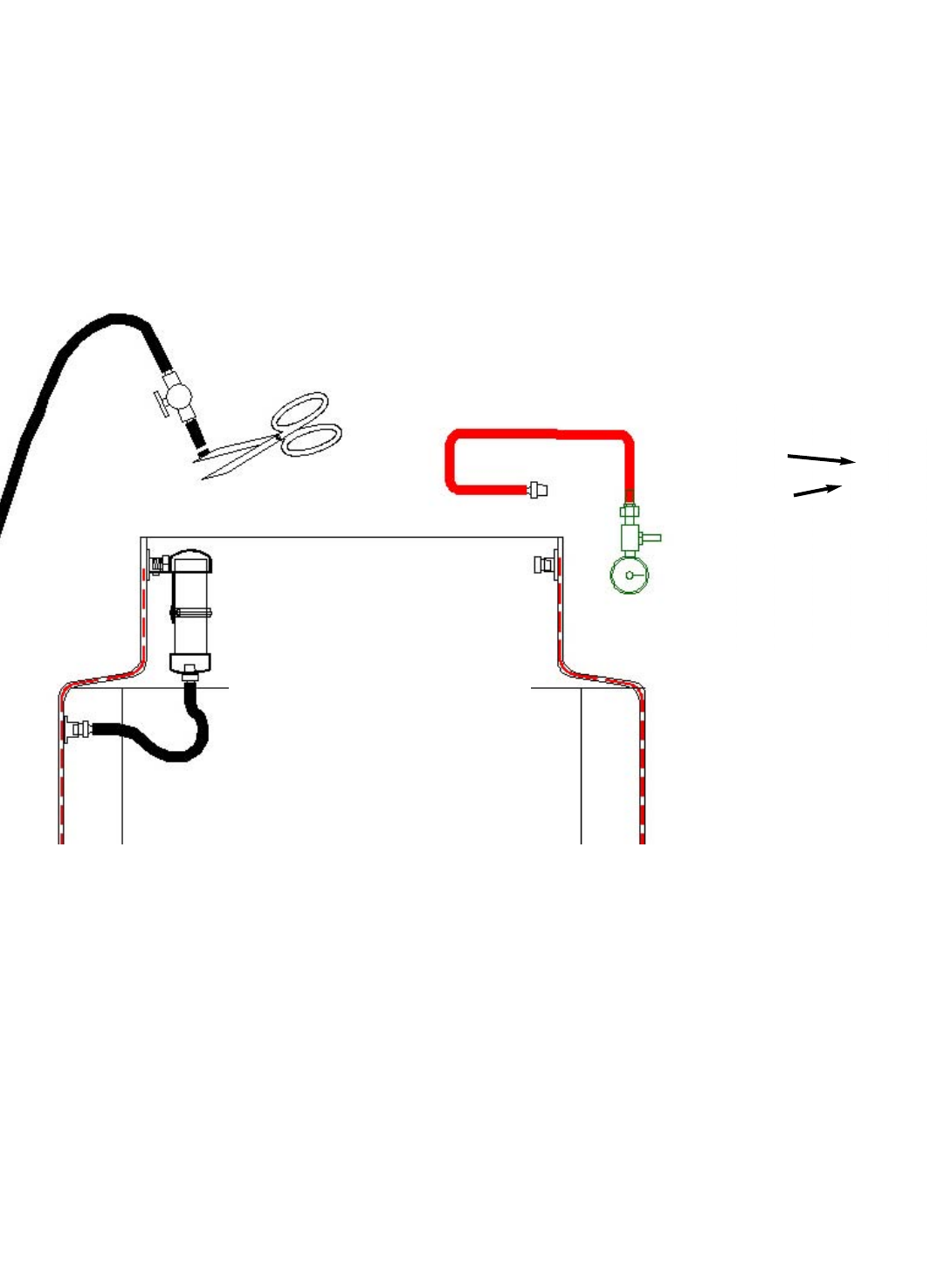

E - CONNECTING TO MANOMETER

E.1 - At this point, after the ALDP test, the interstice should still be holding vacuum. Maintain 20”

of Vacuum and slowly open ball valve to let fluid into the interstice until it exits the venturi assembly.

Visually check whether the fluid level reaches the top of the interstitial space.

E.2 - Cut the barb & ball valve assembly free by cutting the tubing just below it and connect open

end of tubing to the bottom of the primary Manometer.

E.3 - Remove the Barb, Tubing & Combination gauge assembly from the test port fitting on the

side of the sump. Install a threaded pipe plug into the open test port fitting and adjust Primary

manometer bracket so the manometer is in a position clear of the sump cover.

Remove Entire Gauge

Assembly by backing

off threaded barb fitting.

Cut off barb

& ball valve

assembly.

Install PVC Plug

Connect Tubing to

Primary Manometer

P-Traps OK since vacuum fill

method leaves no room for air.

E.4 - It is not uncommon for some interstitial fluid to be lost while connecting the tubing to the primary

manometer. This is ok. Replace lost fluid by topping off manometer with interstitial fluid until the liquid level

reaches just 2 inches below the top of manometer.

E.5 - Hydrostatic Field Integrity Test - Mark the date and time of test and

manometer level. Allow 1 hour to look for a change in level. No change in level or visible leaking means

box passes test.

E.6 - If interstitial test fluid changes its level more than 1/4”, visually look for any signs of leaking around

fittings both interior and exterior to sump. Pay special attention to field installed fittings.

E.7 - If interstitial monitoring is required, install a California Listed Hydrostatic Sensor (LG-113) using the

sensor manufacturer’s fitting. Run sensor cable through the cap assembly (see Fig. E.7). Level sensor

should be set to bottom of manometer. Follow your leak detector manufacturer’s installation instructions.

Cover the manometer with cap and fasten with wire and lead crimp seal.

Continuous Monitoring

Interstitial & Leak

Detection of Secondary

Containment

Sensor Cable

Cap assembly

Fig. E.7

11 ii-B409-DW-10A