Part No 891203 Form No FF060911D

7

KV Push Owner’s Manual

MAINTENANCE

P

ERIODIC MAINTENANCE

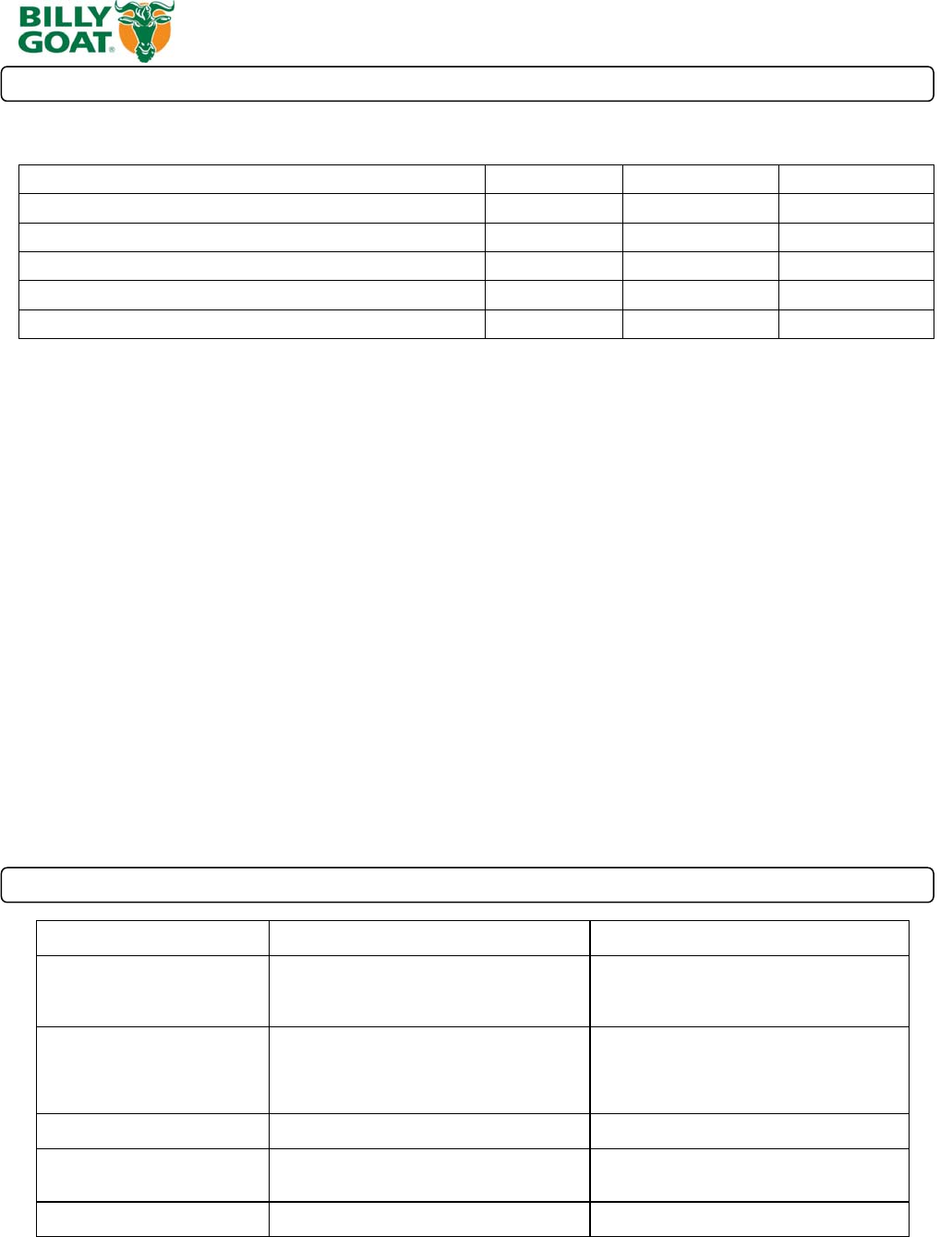

Periodic maintenance should be performed at the following intervals:

Maintenance Operation Every Use (daily) Every 5 hrs (daily) Every 25 Hours

Inspect for loose, worn or damaged parts.

z

Clean Debris bag

z

Check bag strap tightness

z

Engine (See Engine Manual)

Check for excessive vibration

z

Troubleshooting

Problem Possible Cause Solution

Abnormal vibration. · Loose or out of balance impeller or

loose engine

· Check im peller and replace if required.

Check engine

W ill not vacuum or has poor

vacuum performance

· dirty debris bag. Hose kit cap missing.

·Clogged nozzle or exhaust. Excessive

quantity of debris.

· Improper nozzle height

· Clean debris bag. Shake bag clean or

wash. Check for hose kit cap. Unclog

nozzle or exhaust. Allow air to feed with

debris

Engine will not start. · Stop switch off. Throttle in off position.

Engine not in full choke position. Out of

gasoline. Bad or old gasoline.

Sparkplug wire disconnected. Dirty air

cleaner

· Check stop switches, throttle, choke

position and gasoline. Connect spark

plug wire. Clean or replace air filter. Or

contact a qualified service person.

Engine is locked, will not

pull over.

· Debris locked in impeller. Engine

problem.

· See page 5. Contact a engine service

dealer for engine problems

Nozzle scrapes ground in

lowest height setting.

Nozzle height out of adjustment

Adjust nozzle height (See Nozzle

height fine adjustment for hard surfaces

on page 5

Too much dust coming from

bag.

· Vacuuming very dry, brittle or small

debris

· Switch to felt bag (see page 1

accessories)

IMPELLER REMOVAL

1. Wait for engine to cool and disconnect spark plug.

2. Drain fuel and oil from the engine.

3. Remove bag, quick release, and upper handle. Do not kink, stretch, or break control cables, control

housings, or end fittings while removing handles.

4. Remove housing top plate by removing bolts around outside of housing.

5. Leaving engine fastened to top plate, turn it upside down so the impeller is on top.

6. Remove impeller bolt and lock washer and washer.

7. Lift impeller upward. If impeller slides freely, proceed to (step 10).

8. Place two crowbars between impeller and housing on opposite sides. Pry impeller away from engine until it

loosens. Using a penetrating oil can help loosen a stuck impeller.

9. If the impeller does not loosen, use two pry bars and pull the impeller near the hub away from the engine,

this should loosen it and allow you to remove the impeller from shaft. Using a penetrating oil can help loosen a

stuck impeller.

10. Using a new impeller bolt and lockwasher and washer, reinstall new impeller in reverse order.

11. Tighten impeller bolt. Torque impeller bolt to 33-38 Ft. Lbs. (44-51 N.m) (see item 30 on page 15).

12. Reinstall engine onto housing in reverse order of removal.

13. Gas and oil.

14. Reinstall spark plug wire.