Part No. 811202 Form No. F072402A

SECURE LOADER TO TAILGATE OR MOUNTING:

ENGINE: See engine manufacturer’s instructions

for type and amount of oil and gasoline used. Engine must be

level when checking and filling oil and gasoline.

ENGINE SPEED: Controlled by throttle lever on the frame

(16HP Twin on engine). Under normal conditions, operate at

minimum throttle to accomplish your current cleaning task.

FUEL VALVE: Move fuel valve to "ON" position (when provided

on engine).

INTAKE HOSE: Must be attached to front plate to start engine.

CHOKE: Located on engine near engine throttle panel.

STOP SWITCH: Move to on position (when provided).

THROTTLE: Move remote throttle control to fast position. Pull

starting rope to start engine.

IF YOUR UNIT FAILS TO START:

See Troubleshooting on page 12.

Page 5 of 12

OPERATION

16

Like all mechanical tools, reasonable care must

be used when operating machine.

PUT OIL IN ENGINE BEFORE STARTING.

VACUUMING OPERATION

16.2

EXHAUST FLAPPER: Discharging into enclosed container,

position exhaust flapper to desired opening and secure

adjustment knob before starting engine. NOTE: An enclosed

container must capture all debris delivered into it preventing

any debris from blowing back onto unit's engine (see page 1

optional accessories).

INTENDED USE: This machine is designed for vacuuming

leaves, grass clippings and other types of organic litter.

Debris mixed with cans, bottles and small amounts of sand can

be vacuumed; however, it is not this machine's primary

purpose. Vacuuming cans, bottles and sand will affect the

longevity of your machine.

Do not operate if excessive vibration occurs. If excessive

vibration occurs, shut engine off immediately and check for

damaged or worn impeller, loose impeller bolt, loose impeller

key, loose engine or lodged foreign objects. Note: See parts list

for proper impeller bolt torque specifications. (See trouble

shooting section on page 12).

Inspect machine work area and machine before operating.

Make sure that all operators of this equipment are trained

in general machine use and safety.

16.1

STARTING

16.6

HOSE OPERATION TIPS

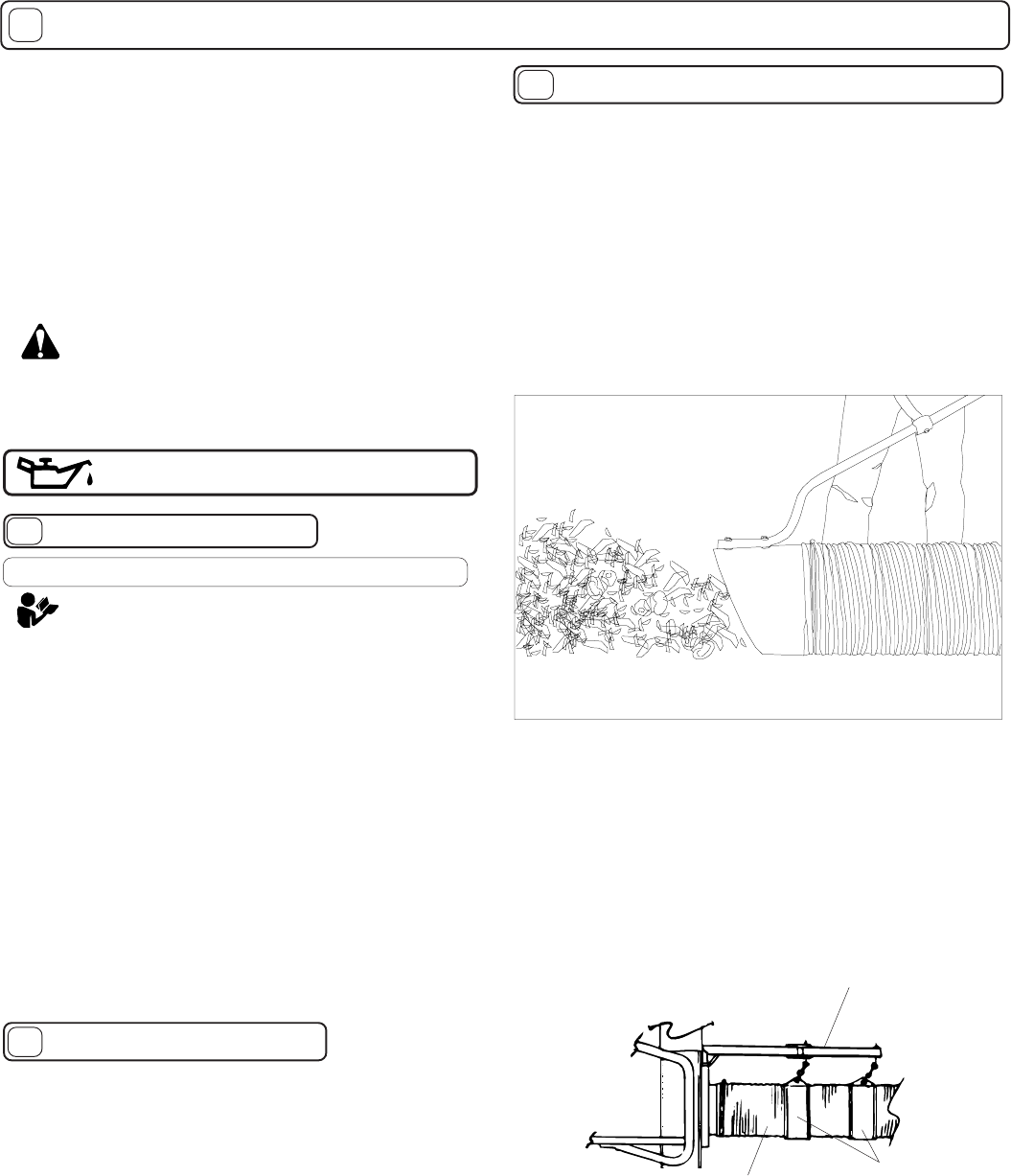

fig. 2

Hose Bands.

Stretch hose

out before

clamping.

Hose

NOZZLE: With machine running and fully assembled, move

nozzle in sweeping motions over debris. For maximum pickup,

move nozzle close to debris, but without blocking air flow into

the nozzle (see figure 1). NOTE: Never bury nozzle into debris.

ADJUSTING HOSE BOOM:

Properly adjusting the boom will prevent most hose clogs from

occurring and will give optimum vacuum performance by

keeping hose straight next to housing (see fig. 2).

Boom Assembly

after hose has

been stretched.

FOR BEST HOSE OPERATION RESULTS, FOLLOW THESE

RECOMMENDATIONS.

Keep hose as straight as possible during operation for best

pick-up and to avoid clogs.

Avoid sharp bends in hose which will reduce efficiency and may

promote clogs.

NEVER DRAG HOSE. Always remove and store hose before

transporting unit.

THE HOSE IS A REPLACEABLE WEAR ITEM.

fig. 1