PAGE 22 — ST-4125D/ST-6125D SUBMERSIBLE PUMPS — OPERATION AND PARTS MANUAL — REV. #1 (06/12/08)

ST-4125D/ST-6125D

—

MAINTENANCE

LUBRICATION

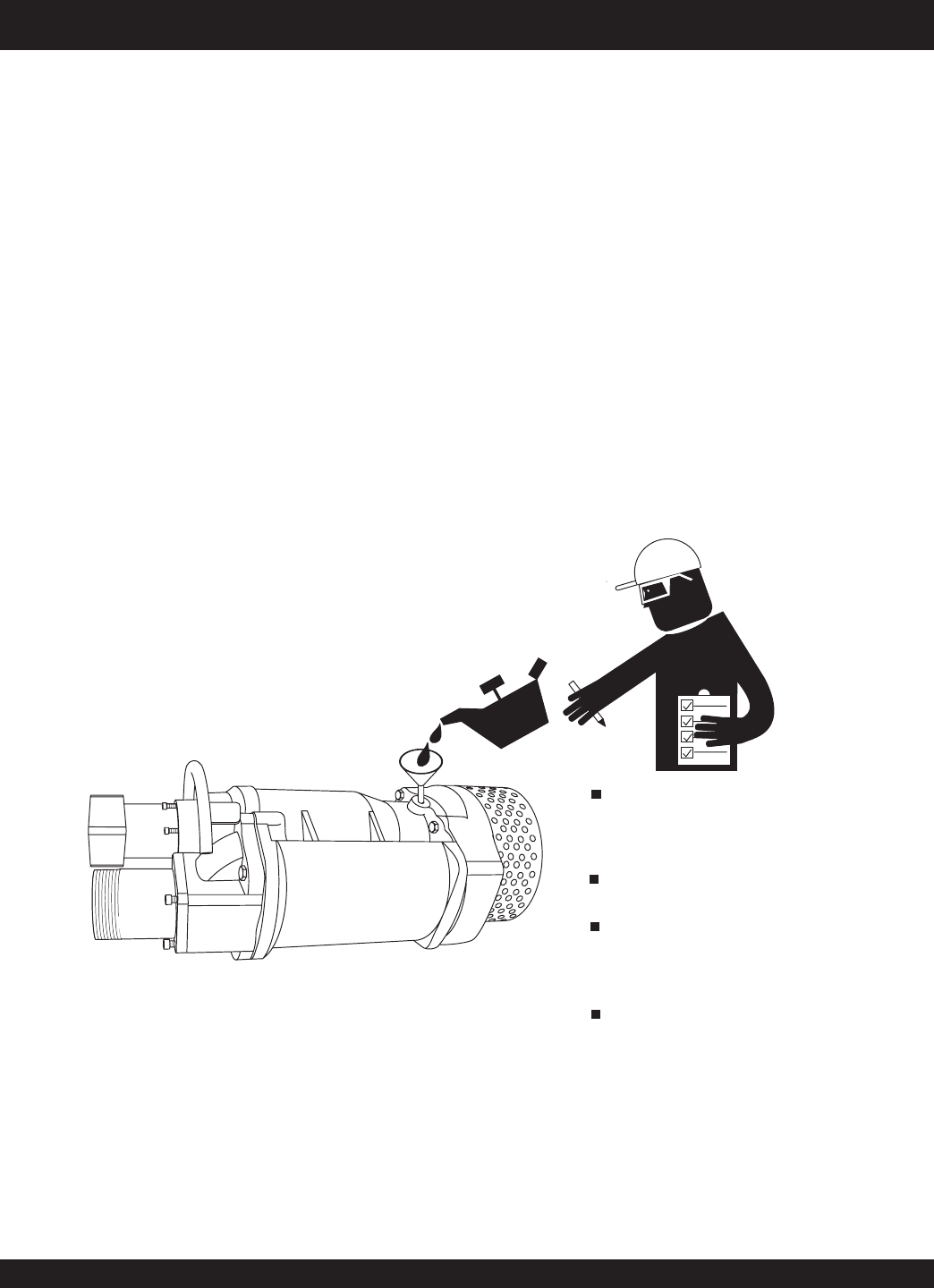

To check the oil level of the mechanical seal perform the

following:

1. Lay the pump (Figure 17) on its side with the oil plug facing

upwards.

2. Remove oil fill plug.

3. Visually inspect oil plug hole to verify that oil cavity is full

enough to cover seal spring. Check every 300 hours, change

hydraulic oil every 6 months (1,000 hours) or as needed.

4. While checking the hydraulic oil level, also check the

condition of the hydraulic oil in the seal cavity . Block the

opening with a finger and roll pump to one side to drain

oil into a small transparent container. If oil is cloudy or has

water in it, drain oil from pump cavity and replace hydrau-

lic oil. Check the seal for wear damage.

5. If oil level is low fill with SAE 10 weight non-detergent

hydraulic oil (i.e. Shell Turbo 32 or equivalent). Fill oil cavity

75% to 85% full (allow air space for expansion). Pump oil

cavity capacity is approximately 180 cc.

IMPELLER

1. Make sure the clearance between the impeller and the

friction disk is approximately .012 - .020 inches (.304 - .508

mm.)

2. If impeller is defective or badly worn, replace impeller imme-

diately.

Figure 17. Checking Hydraulic Oil

FILL TO 75-80% CAPACITY

(APPROXIMATELY 180 CC.)

LAY PUMP FLAT

ON ITS SIDE

FILL WITH 10 WEIGHT NON-

DETERGENT HYDRAULIC

OIL. USE SHELL TURBO 32

OR EQUIVALENT.

REMOVE FILL PLUG, AND

VISUALLY INSPECT THAT

OIL CAVITY IS FULL ENOUGH

TO COVER SEAL SPRING.

CHECK HYDRAULIC OIL

EVERY 300 HOURS. CHANGE

EVERY 6 MONTHS OR AS

NEEDED.