ED810 INSTRUCTION MANUAL 27-02-07 4

INSTALLATION

Note only EDL manufactured sensors, which are suitably certified can be connected to the

ED810 and fitted in the Hazardous Area. The ED810 control unit and all uncertified

equipment should be located in the Safe Area only.

Control Unit: The unit should be mounted in a convenient position for the operator away from

possible mechanical damage or ingress of moisture and allowing the clear hinged lid to swing

open for ease of calibration etc.

Remove the front cover by unscrewing the thumb screws and then removing the hinges. Fit

mounting screws in the slots now exposed. To obtain access to the two lower slotted holes

remove the terminal cover.

Note it is not usually necessary to remove the front panel and PCB assembly during

installation or calibration.

The power supply should not allow greater than 0.25V drop along its length when carrying

1A plus current required for ancillary equipment connected. Twin core double insulated 15A

cable is normally adequate. The main DC input fuse is normally 2A rated but may be

increased to 3A allowing for ancillary equipment. External fusing may be necessary and

should be considered.

The DC supply should not deviate by more than +/- 25% of the operating voltage stated on

the serial number label. It is advisable to wire the gas detector via its own main switch so that

it may become operational without having other electrical equipment energised. Allowing a

test for gas to be made without the danger of explosion through spark ignition.

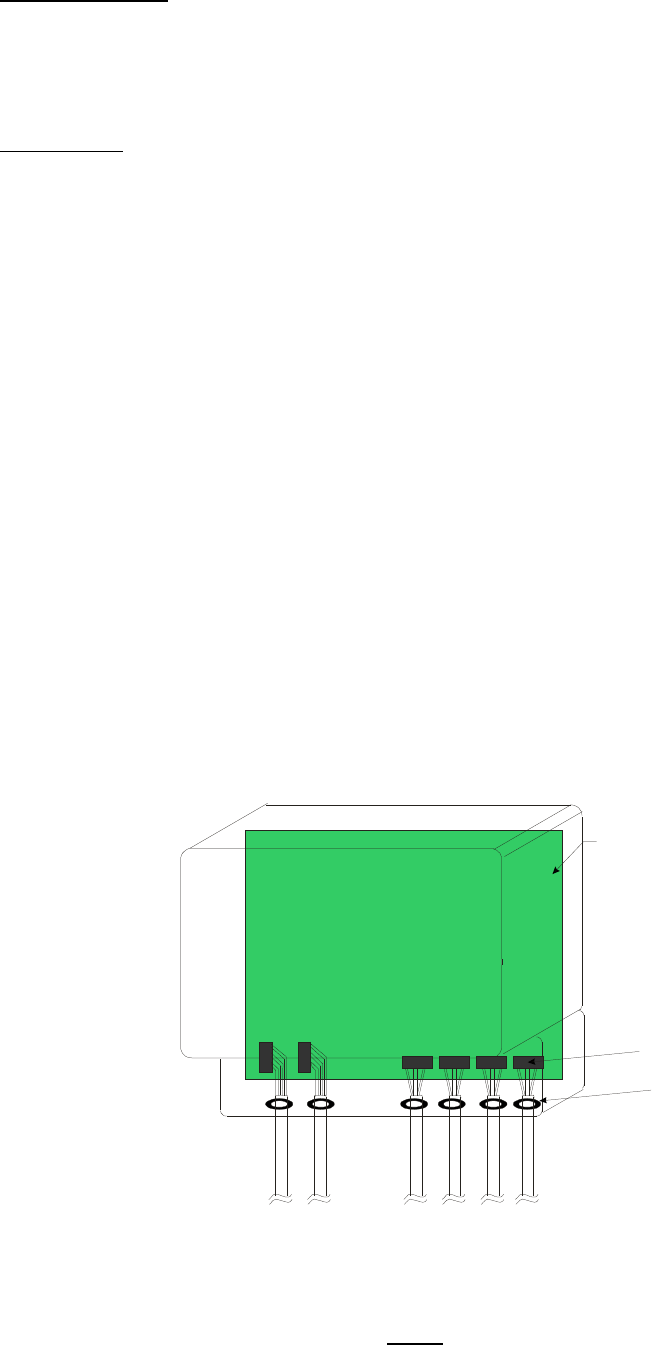

Sensor cable entry must only be made through the intended hole via either the standard

rubber grommet or cable gland. Sensor cables must not cross or lie over each other or safe

area cables see fig1 below.

FIG 1

BB PCB

TERMINAL BLOCK

RUBBER GROMMETS OR

CABLE GLAND KEEPING

CABLES SEPARATED

HAZARDOUS AREA CABLES

SAFE AREA CABLES