Manual 2100-346

Page 9

WIRING INSTRUCTIONS

GENERAL

All wiring must be installed in accordance with the National

Electrical Code and local codes. In Canada, all wiring must

be installed in accordance with the Canadian Electrical

Code and in accordance with the regulations of the

authorities having jurisdiction. Power supply voltage must

conform to the voltage shown on the unit serial plate. A

wiring diagram of the unit is attached to the inside of the

electrical cover. The power supply shall be sized and fused

according to the specification supplied. A ground lug is

supplied in the control compartment for equipment ground.

The unit rating plate lists a “Maximum Time Delay Fuse” or

HACR type” circuit breaker that is to be used with the

equipment. The correct size must be used for proper circuit

protection and also to assure that there will be no nuisance

tripping due to the momentary high starting current of the

compressor motor.

CONTROL CIRCUIT WIRING

For split systems, the minimum control circuit wiring gauge

needed to insure proper operation of all controls in both

indoor and outdoor units will depend on two factors:

1. The rated VA of the control circuit transformer.

2. The maximum total distance of the control circuit

wiring. (This is the distance between the wall

thermostat to the indoor unit plus the distance

between the indoor unit to the outdoor unit.)

The following table should be used to determine proper

gauge of control circuit wiring required.

Example: 1. Control circuit transformer rated at 40 VA

2. Maximum total distance of control circuit

wiring 85 feet.

From Table 6, minimum of 18 gauge wire should be used in

the control circuit wiring.

For control circuit transformers rated other than those listed,

use the next lower rated transformer listed.

Example: 1. Control circuit transformer rated at 55 VA

From table use 50VA transformer.

There are two (2) separate control diagrams for fossil fuel

furnaces with air conditioners.

Control diagrams for the various circuit which could be

encountered with blower coils can be found in the

installation instructions of the blower coil.

WALL THERMOSTATS

The following wall thermostats and subbases should be

used as indicated, depending on the application.

TABLE 7

CONTROL DIAGRAMS

metsyS

ecanruFsaG

margaiDlortnoC

ecanruFliO

margaiDlortnoC

sledoMllA001-1904101-1904

TABLE 8

WALL THERMOSTAT and SUBBASE

COMBINATIONS

tatsomrehTesabbuSserutaeFetanimoderP

200-3048

113F78T

300-4048

0221A925Q

yrucreM;loocegats1,taehegats1

otua-no:naFlooc-ffo-taeh:metsyS

140-3048

C-4308T

---

yrucreM;loocegats1,taehegats1

otua-no:naFlooc-ffo-taeh:metsyS

530-3048

08-59F1

---

loocegats2,taehegats2

elbammargorP

cinortcelE

240-3048

G1158T

---

loocegats1,taehegats2

looc-otua-ffo-taeh:metsyS

cinortcelEotua-no:naF

340-3048

002MC

---

loocegats1,taehegats1

otua-no:naFlooc-ffo-taeh:metsyS

noitcApanS

720-3048

17-29F1

---

loocegats2,taehegats3

elbammargorP

cinortcelE

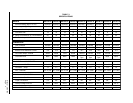

TABLE 6

CONTROL CIRCUIT WIRING

foAVdetaR

tiucriClortnoC

remrofsnarT

remrofsnarT

yradnoceS

V42@ALF

latoTmumixM

foecnatsiD

tiucriClortnoC

teeFnigniriW

046.1

56eguag02

09eguag81

541eguag61

032eguag41

051.2

54eguag02

06eguag81

001eguag61

061eguag41

052eguag21

567.2

04eguag02

55eguag81

58eguag61

531eguag41

012eguag21