156 720 606 601

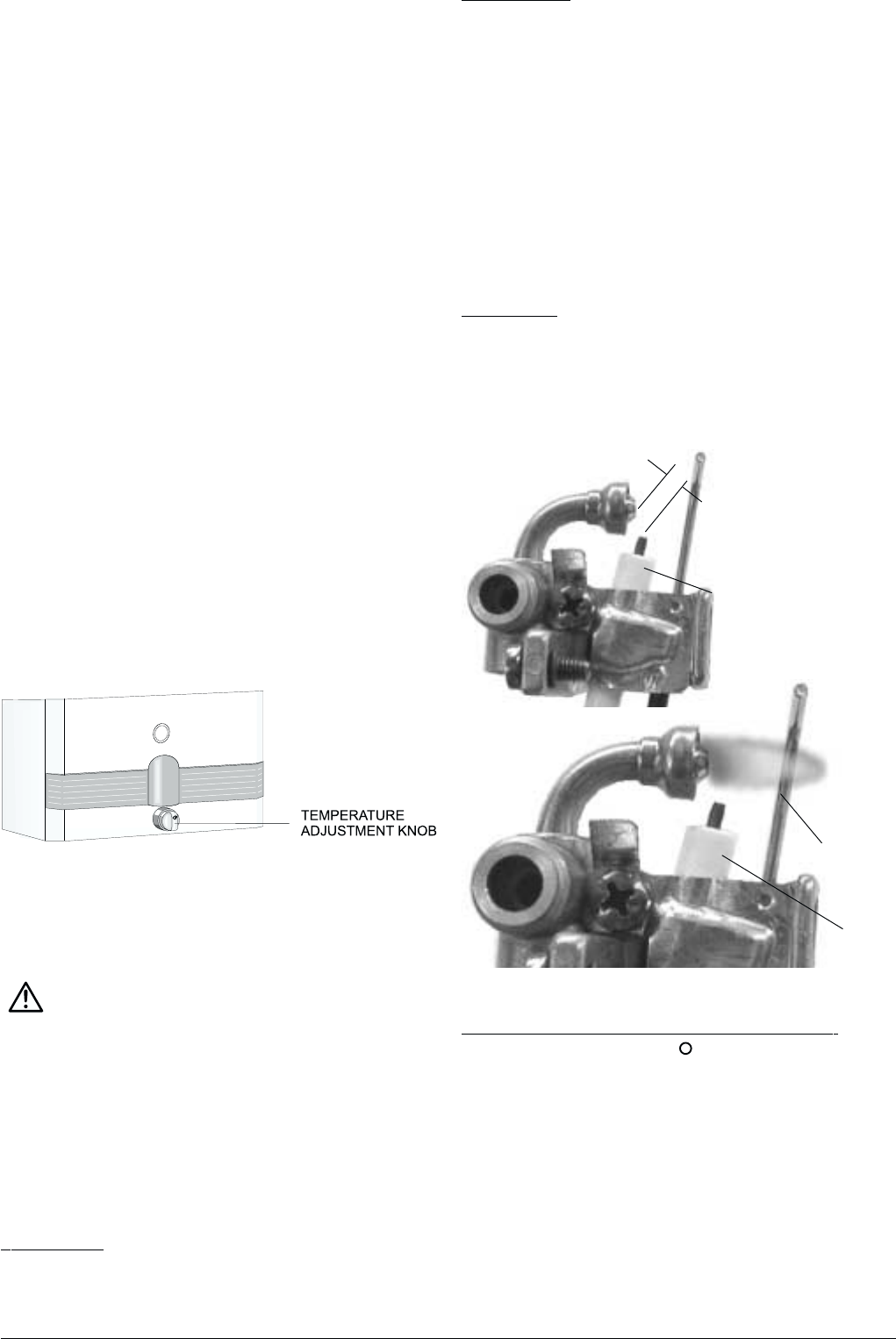

Fig. 12 - Characteristic Pilot Flame

Flame sensor

Piezo

Electrode

Water Valve (Part # 8707002802): The water valve on

this heater should be serviced periodically. Lubricate

component #36 on page 20 with a small amount of silicon,

faucet or lithium grease every two years to keep its o rings

fresh and pushrod sliding smoothly. Every 3-5 years replace

component #36 on page 20. The frequency will depend on

the mineral content of the water and conditions of use or

whenever signs of corrosion appear at the gas and water

valve joint. Periodically check that the water inlet filter (#27

on page 20) is clean as well.

NOTE: If water valve is removed, be sure to also inspect the

o ring seal on the end of the right hand side water pipe

before re-installing. Lubricating the o ring with lithium or

faucet and valve grease is recommended.

Pilot Flame: The pilot flame should burn with a clean, sharp,

blue flame and should resemble the diagram in Fig. 12. If

the flame is soft and yellow, the pilot burner orifice may

need to be cleaned or serviced. The pilot flame should be

approximately 2 inches long, extending past the flame sensor.

If the flame is too small, it will not reach the flame sensor

and the burners will not come on.

3mm

Correct gap between pilot

burner tip and electrode tip

Piezo Electrode

Fig. 11 - Temperature Adjustment Knob

140° and 95°F at various flow rates between 2.0 and 4.0

gallons per minute. The position you select on the

temperature selector dial will depend on the temperature of

the incoming water (50°F is average in the U.S.). In warm

weather regions where the incoming cold water is generally

warmer, or during the hot weather months in some other

areas a midway setting on the temperature selector knob

will produce a temperature rise of about 70°F, giving an

output of approximately 120°F. At this setting, if it is still

necessary, one could mix a small amount of cold water in a

shower and have a comfortable shower at about 3 gallons/

minute. During the colder months, or in cold climate areas,

it might be necessary to set the control all the way clockwise

to the right for maximum temperature rise.

Do not supply the AquaStar 125FX with preheated water.

For this type of application, purchase a solar model 125 B

LPS or 125 B NGS.

If the inlet water temperature to the water heater is very

warm the heater can produce temperatures that may be

found to be too hot. A temperature balance shower valve

can automatically mix in cold water to reduce such hot water

temperature, in the event of any temperature instability with

the use of a temperature balance shower valve, refer to

shower valve manufactures instructions for internal

adjustment setting. Adjustments should be made to the

hottest setting in the shower valve. Additionally the

temperature control of the heater can be adjusted to produce

a more comfortable hot water temperature.

MAINTENANCE AND SERVICE

REVIEW MAINTENANCE TABLE ON

THE BACK OF THIS MANUAL

Approximately once a year, the AquaStar should be checked

and cleaned. To remove the front cover, first remove the

incandescent particle tray, then pull off the temperature

adjustment knob and unscrew and remove the plastic collar.

Unscrew the central screw located at the bottom of the

front cover. Pull main cover out toward you and lift up and

out. THE FOLLOWING OPERATIONS SHOULD BE

PERFORMED BY A QUALIFIED SERVICE PERSON:

Vent System: Should be checked annually. Clean and repair

as needed.

To clean the pilot burner and/or the pilot orifice: Turn off

the gas at the unit (Position ‘ ’). Remove the cover of the

heater. To do so, pull off the temperature knob and unscrew

and remove the temperature knob collar. Pull main cover

out toward you and lift up and out. The pilot orifices should

also be cleaned or replaced. Do not enlarge the orifice

(see fig. 13). Do not use any wire or sharp object to clean

orifices. Natural gas orifices are large enough that you can

usually clean them by blowing through them. LP orifices, on

the other hand, are too small to clean and should be replaced.

See #3 in Trouble Shooting Section. To access the pilot

orifice, remove 2 screws holding pilot assembly in place.

Then loosen the compression fitting and lift up pilot burner

to expose pilot orifice.