7

GROUNDING INSTRUCTIONS

This boiler must be grounded in accordance with the National

Electrical Code and/or local codes. Boiler is polarity sensitive;

correct wiring is imperative for proper operation.

This boiler must be connected to a grounded metal, permanent

wiring system, or an equipment grounding conductor must be

run with the circuit conductors and connected to the equipment

grounding terminal or lead on the boiler.

INLET WATER CONSIDERATIONS

To minimize the amount of condensate, a minimum inlet

water temperature to the heat exchanger of 120°F (49°C)

shall be maintained. This temperature can be acquired by

returning120°F(49°C)waterfromtheremotestoragetankto

the boiler or by installing a by-pass loop between the boil er’s

inlet and outlet connec tions. When installing a by-pass loop, a

remote probe MUST be used, see SYSTEM INSTALLATION.

Circulating water through the boiler and to the remote storage

tank(ifapplicable)isaccomplishedbyapumponVWmodels

only. For hot water heating systems using the VB model,

the circulating pump is NOT provided on standard models

(optional)andmustbefieldinstalled.

CORRECT GAS

MAKE SURE THE GAS ON WHICH THE BOILER WILL

OPERATE IS THE SAME AS THAT SPECI FIED ON THE

BOILER RATING PLATE. DO NOT INSTALL THE BOILER

IF EQUIPPED FOR A DIFFERENT TYPE OF GAS — CON-

SULT YOUR SUPPLIER.

PRECAUTIONS

IF THE UNIT IS EXPOSED TO THE FOLLOWING, DO

NOT OPERATE UNTIL ALL CORRECTIVE STEPS HAVE

BEEN MADE BY A QUALIFIED SERVICE AGENT:

1. EXPOSURE TO FIRE.

2. IF DAMAGED.

3. FIRING WITHOUT WATER.

4. SOOTING.

IF THE BOILER HAS BEEN EXPOSED TO FLOODING,

IT MUST BE REPLACED.

LIQUEFIED PETROLEUM GAS MODELS

Boilersforpropaneorliquefiedpetroleumgas(LPG)are

different from natural gas models. A natural gas boiler will not

function safely on LP gas and no attempt should be made to

convert a boiler from natural gas to LP gas.

LP gas must be used with great caution. It is highly

explosive and heavier than air. It collects first in the low

areas making its odor difficult to detect at nose level.

If LP gas is present or even suspected, do not attempt

to find the cause yourself. Leave the building, leaving

doors open to ventilate, then call your gas supplier or

service agent. Keep area clear until a service call has

been made.

At times you may not be able to smell an LP gas leak.

One cause is odor fade, which is a loss of the chemical

odorant that gives LP gas its distinctive smell. Another

cause can be your physical condition, such as having

a cold or diminishing sense of smell with age. For

these reasons, the use of a propane gas detector is

recommended.

IF YOU EXPERIENCE AN OUT OF GAS SITUATION, DO

NOT TRY TO RELIGHT APPLIANCES YOURSELF. Call

your local service agent. Only trained LP professionals

should conduct the required safety checks in accordance

with industry standards.

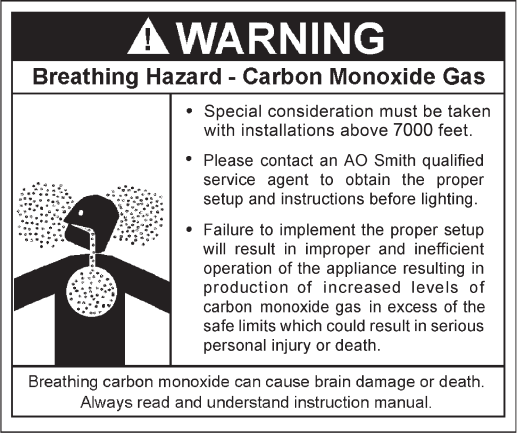

HIGH ALTITUDE INSTALLATIONS

Rated inputs are suitable up to 7000 feet (2134m)

elevation. Consult the factory for installation at altitudes

over7000feet(2134m).

FIELD INSTALLED COMPONENTS

When installing the boiler, the follow ing compo nents

MUST be installed:

1)CirculatingPump(Hydronic)

2)TankTemperatureControlProbe(HotWaterSupply)

3)RemoteTemperatureControlProbe(Hydronic)

4)StorageTankT&PReliefValve

5)ManualGasShutoffValve(Supply)

Check the FEATURES AND CONTROLS section for further

information.