12

3. The correct test instruments are:

•CO

2

indicator or 0

2

analyzer

• CO indicator

• Stack thermometer

• Draft gauge or inclined manometer

• U-tube manometer or calibrated 0-10” and 0-35” w.c.

pressure gauge

• Combination volt/ammeter.

Suggested safety device test procedures are:

A. While heater is operating, turn valve, main burner and pilot

gas line manual gas cocks to the OFF position. Burner should

shutdown within 3-4 seconds and lockout on flame failure,

requiring reset of the flame safeguard device.

B. While heater is operating, lower the setting of each of (2)

operating thermostats (one at a time). During this setting

change, the burner should shutdown when the called for

temperature is less than the temperature indicated on the

thermometer. Restore the settings to original values and burner

should restart.

Should any of the above operating test fail, replace the involved

component.

MAINTENANCE

GENERAL

Water heater maintenance includes periodic tank flushing and

cleaning, and removal of lime scale. The power burner should

be inspected and adjusted to maintain proper combustion. Refer

to the following table. A periodic inspection of the venting system

should be made. Where used, the water heating system

circulating pump should be oiled.

KEEP APPLIANCE AREA CLEAR AND FREE FROM

COMBUSTIBLE MATERIALS, GASOLINE AND OTHER

FLAMMABLE VAPORS AND LIQUIDS.

FLUSHING

1. Turn off the heater electrical disconnect switch.

• For convenience, the switch on the outside of the control

compartment can be used.

2. Open the drain valve and allow water to flow until it runs clean.

3. Close the drain valve when finished flushing.

4. Turn on the heater electrical disconnect switch.

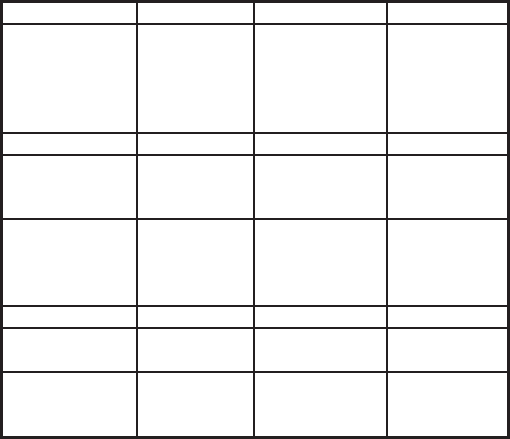

MAINTENANCE SCHEDULE

Component Operation Interval Required

Flushing Monthly

Sediment

Tank Removal Semi-Annually

Lime Scale UN•LIME

®

Removal As Required Delimer

Relief Valve Inspect Semi-Annually

Power Burner SAE No. 20

Motor(1) Inspect Quarterly non-detergent

motor oil

Power Burner Combustion

and Ignition Inspection Semi-Annually test kit &

Device(2) test

specifications

Main Burner Check Flame Annually

Flue Baffle

Pipe(3) Cleaning As Required Wire Brush

Vent System

and Barometric Inspect Semi-Annually Draft Gauge

Damper

(1) If furnished with oiling provisions

(2) If flange gasket is damaged, it must be repaired.

(3) COF and COBT Only.

DRAINING

The heater must be drained if it is to be shut down or exposed to

freezing temperatures. Maintenance and service procedures may

also require draining the heater.

1. Tun off the heater electrical disconnect switch.

2. Close the cold water inlet valve to heater.

3. Open a nearby hot water faucet to vent the system.

4. Open the heater drain valve.

5. If the heater is being drained for an extended shutdown, it is

suggested the drain valve be left open during this period.

• Follow FILLING instructions when restoring hot water service

SEDIMENT REMOVAL

Waterborne impurities consist of fine particles of soil and sand

which settle out and form a layer of sediment on the bottom of the

tank.

For convenience, sediment removal and lime scale removal

should be performed at the same time.

LIME SCALE REMOVAL

The amount of calcium (lime) released from water is indirect

proportion to water temperature and usage. The higher the water

temperature or water usage, the more lime deposits are dropped

out of the water. This is the lime scale which forms in pipes, heaters

and on cooking utensils.