21

VENT ATTENUATION ASSEMBLY

INSTALLATION INSTRUCTIONS

The Vent Attenuation Assembly (VAA) is designed to provide a

reduction in fan noise created in the blower wheel. This installation of

this VAA is optional. Review directions thoroughly prior to installing

the new VAA. Please contact the manufacturer of the water heater as

shown in the instruction manual with any questions or for additional

product support.

VENT ATTENUATION ASSEMBLY KIT PARTS LIST

The kit consists of the following items. If a part is missing, use the

contact information in the instruction manual to acquire missing

component(s).

• vent attenuation assembly

• flexible tubing

• hose barb

• hex plug (installed on VAA)

• instruction sheet

VENT ATTENUATION ASSEMBLY INSTALLATION

The VAA is designed for both vertical and horizontal installations. The

vertical installation does not require the additional hose barb and flexible

tubing. However, the horizontal installation will require the hose barb

and flexible tubing to release condensate buildup from the VAA. See

instructions and diagrams that follow for a more detailed description.

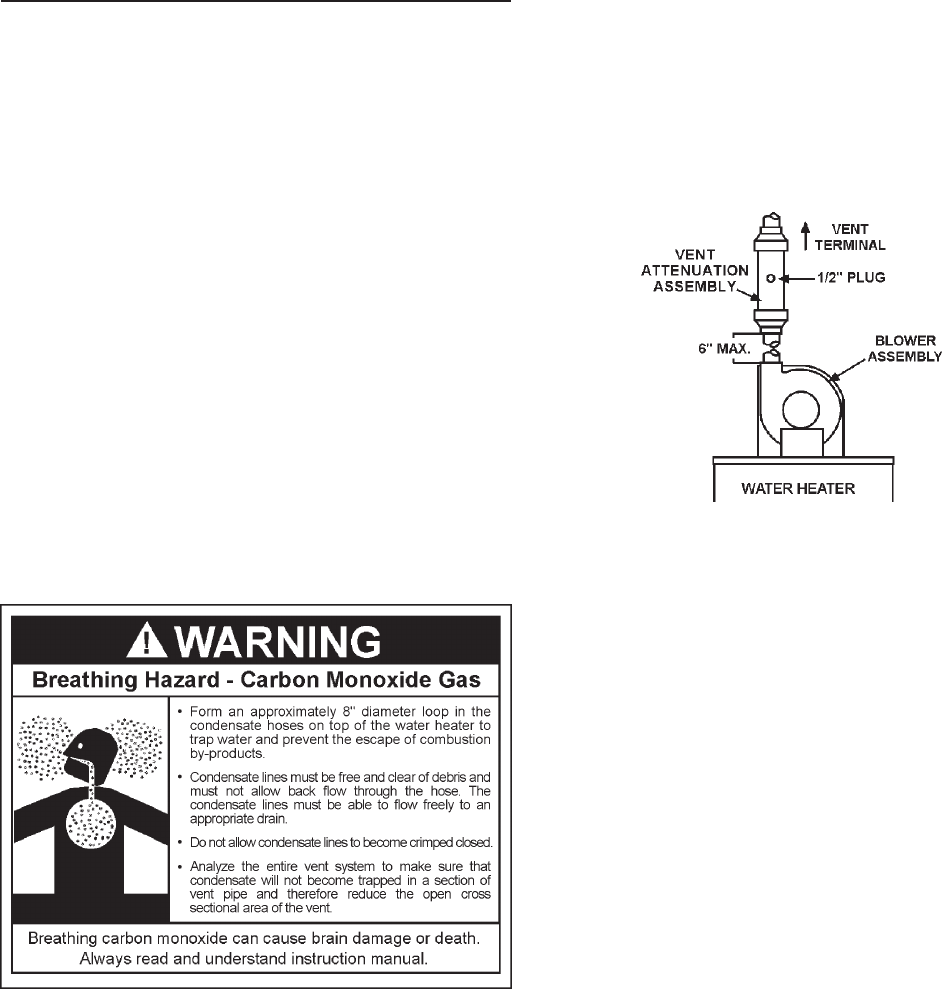

Vertical VAA Installations (Recommended)

1. The VAA is designed to accept two inch PVC pipe into the adapters

on both ends. The VAA can be installed to the piping from either side

(there is no specific inlet or outlet). For optimum performance, install

VAA as close as possible to the blower assembly.

2. Use standard PVC cement (not included with kit) and glue the two

inch PVC pipe coming from the blower into the VAA.

3. Perform the same sequence on the PVC pipe coming from the

exhaust side (vent terminal side) of the VAA.

4. Make sure the VAA and vent pipe is supported securely to a permanent

fixture (stud or wall). Use standard support straps (not supplied with

kit) that may be found at a local hardware store. Failure to properly

support the VAA and the surrounding vent pipe could create a

hazardous situation. DO NOT puncture any surface of the VAA.

5. Confirm that the hex plug is securely installed in the 1/2" fitting

found on the center of the VAA pipe. It is imperative that the plug

is secure and air tight to prevent any combustion gases escaping

into the room. If the plug is not securely tightened, remove and

reinstall using Teflon tape on the threads. Once installed along

with the rest of the vent configuration, make sure to operate the

unit through at least one heat up cycle to ensure there is no leakage

around the plug or any joints of the VAA or vent pipe system.

FIGURE 22: Typical Vertical Installation

Horizontal VAA Installations

1. The VAA is designed to accept two inch PVC pipe into the adapters on

both ends. The VAA can be installed to the piping from either side

(there is no specific inlet or outlet). For optimum performance, install

VAA as close as possible to the blower assembly.

2. Use standard PVC cement (not included with kit) and glue the two

inch PVC pipe coming from the blower into the VAA. Make sure

the 1/2" fitting is on the bottom side of the VAA. This will be used

to run the condensate hose to a suitable drain. See typical vent

installation in Figure 23.

3. Perform the same sequence on the PVC pipe coming from the

exhaust side (vent terminal side) of the VAA.

4. Make sure the VAA and vent pipe is supported securely to a permanent

fixture (stud or wall). Use standard support straps (not supplied with

kit) that may be found at a local hardware store. Failure to properly

support the VAA and the surrounding vent pipe could create a

hazardous situation. DO NOT puncture any surface of theVAA.

5. Remove hex plug from the center pipe of the VAA. Locate the

hose barb and install into the 1/2" fitting on the center of the VAA.

Using Teflon tape on the threads, install hose barb into 1/2" fitting

securely. It is imperative that the hose barb is secure and tight to

prevent any combustion gases escaping into the room.

6. Locate flexible tubing. Slide one end of tube over the hose barb

located on the center pipe of the VAA. The ridges on the hose

barb should prevent the tube from sliding off, however, to ensure

there are no leaks and possible dislocation from hose barb, use a

wire tie or hose clamp (not supplied with kit) and secure.

7. Take the other end of the flexible tubing and form an 8 inch (20

cm) diameter circle approximately 3 feet (91 cm) down from the

hose barb located in the VAA. To ensure that the circle (loop)

maintains its shape, use two wire ties (not supplied with kit) to

secure it.