Performing maintenance

62 Instruction manual ADM

12

s

12.3 Water-side

maintenance

12.3.1 Introduction

The following steps must be carried out on the water side:

1. Checking the anodes.

2. Descaling and cleaning the tank.

12.3.2 Checking the anodes

Timely replacement of the anodes extends the service life of the appliance. The

appliance's anodes must be replaced as soon as they are 60% or more

consumed (take this into consideration when determining the maintenance

frequency).

Warning

The draught diverter and the cover may be hot.

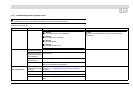

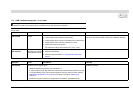

1. Remove the protective cover from the control column by unscrewing the 4

screws in the cover.

2. Detach the wiring for the flue gas thermostat from the connector block and

remove the cable from the strain relief.

3. Remove the cable clamps holding the flue gas thermostat cable.

4. Disconnect the draught diverter from the flue gas discharge.

5. Undo the screws on the draught diverter.

6. Remove the draught diverter from the appliance.

7. Undo the screws of the lid in the top side of the appliance.

8. Remove the lid from the appliance.

9. Remove the sealing ring from the appliance.

10. Loosen the anodes using suitable tools.

11. Check the anodes, and replace them if necessary.

12. Now also check the flue baffles (12.4.4 "Checking the flue baffles"). If

necessary, replace them.

13. Place a new sealing ring on the rim of the tank and re-fit the lid.

14. Fit the draught diverter (3.9.2 "Fitting the draught diverter").

15. Feed the cable of the flue gas thermostat through the strain relief and attach

the wiring to the connector block (14.2 "Electrical Diagrams ADM").

16. Refit the cable clamps to the appliance and draught diverter.

17. Re-fit the protective cover.

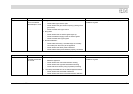

12.3.3 Descaling and cleaning the tank

Scale and lime buildup prevent effective conduction of the heat to the water.

Periodic cleaning and descaling prevents buildup of these deposits. This

increases the service life of the appliance, and also improves the heating

process.

Take the rate of scale formation into account when deciding on maintenance

frequency. Scale formation depends on the local water composition, the water

consumption and the water temperature setting. A water temperature setting of

maximum 60°C is recommended for prevention of excessive scale buildup.

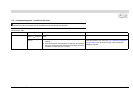

To ensure the perfectly watertight sealing of a cleaning opening, the gasket (6),

O-ring (7), sealing rings (4), bolts (3) and possibly the lid (5) should be replaced

with new components after opening (see the figure). A special set is obtainable

from the supplier/manufacturer.