ACGSS02307

Page 2 of 4

CATEGORY IV LISTED

• Requires AL29-4C gas tight rust resistant

venting material

PROFESSIONAL START-UP SERVICE

FURNISHED

• Assures optimum performance for each

installation

MEETS ASHRAE/IESNA 90.1-1999

5 YEAR HEAT EXCHANGER WARRANTY

• For complete information, consult written

warranty or contact A. O. Smith

OTHER VF

™

BOILER FEATURES:

• ASME 160# W.P.

• ASME PRESSURE RELIEF VALVE 125#

• FACTORY MOUNTED FLOW SWITCH

• MEETS CSD-1 CODE-–FACTORY STANDARD

• BRASS DRAIN VALVE

• LOW GAS PRESSURE SWITCH

• DIGITAL INLET/OUTLET

TEMPERATURE READ OUT

• MANUAL RESET HI-LIMIT

• ALL BRONZE FACTORY MOUNTED PUMP

VF

™

BOILER APPROVED OPTIONS:

❑ SEQUENCING PANEL

❑ ALARM BELL

❑ SIDEWALL VENT KITS

❑ VERTICAL AND HORIZONTAL

DIRECT VENT KITS

❑ SKID-MOUNTED SYSTEMS

❑ DRY CONTACTS FOR ANY

BOILER FAILURE

❑ LOW WATER CUTOFF

❑ LP GAS

❑ CUPRO-NICKEL HEAT

EXCHANGER TUBES

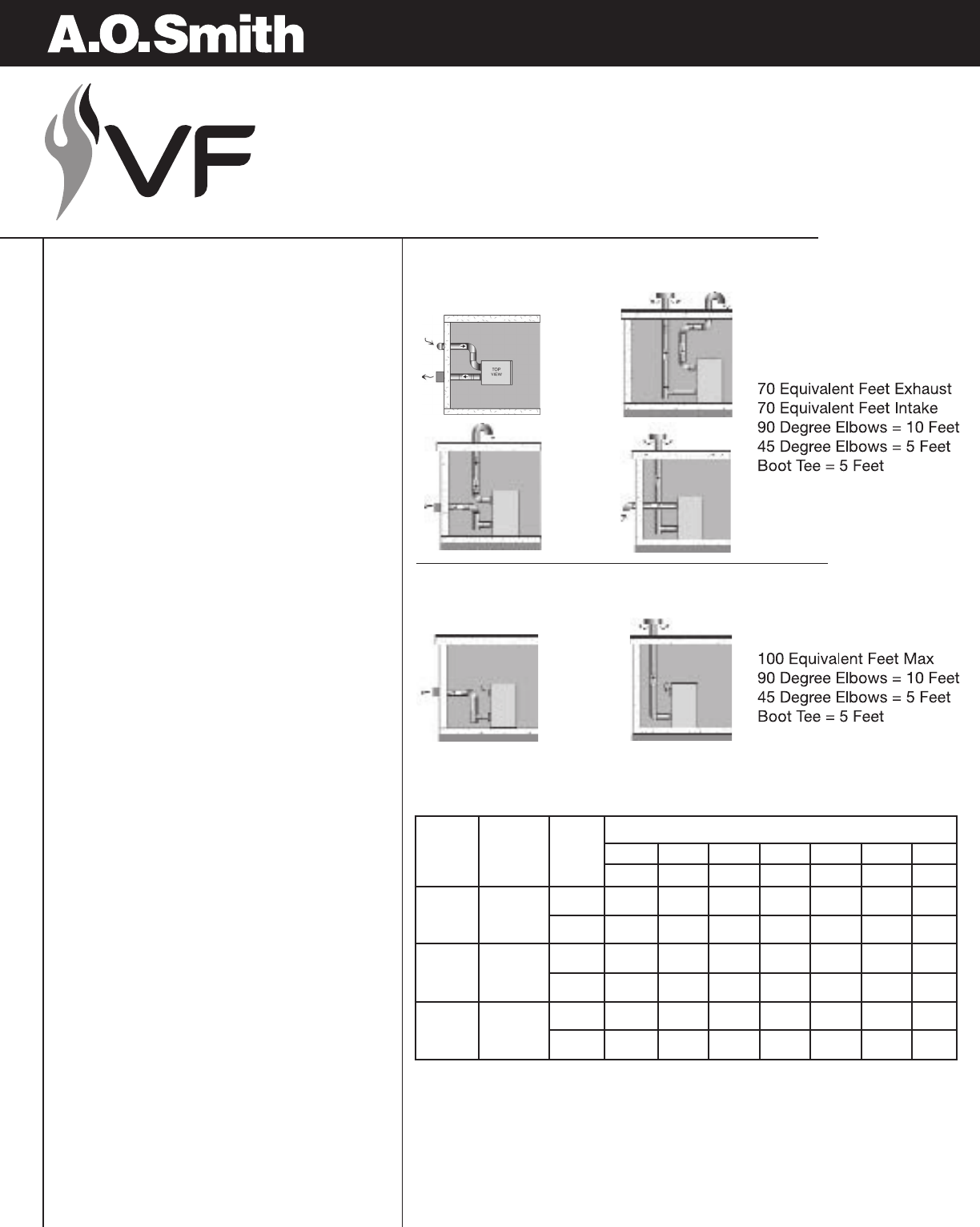

Please consult latest edition of the Installation Manual for detailed venting information and

maximum/minimum venting distances.

Model

No.

Input

Rating

Btu/hr

Water

Flow

Temperature Rise - °F (°C)

40 60 80 90 100 120 140

(22) (33) (44) (90) (56) (67) (78)

VW-500 500,000

GPH 1,268 845 634 563 507 423 362

LPH 4,797 3,198 2,399 2,132 1,919 1,599 1,371

VW-750 750,000

GPH 1,901 1,268 951 845 761 634 543

LPH 7,196 4,797 3,598 3,198 2,878 2,399 2,056

VW-1000 1,000,000

GPH 2,535 1,690 1,268 1,127 1,014 845 724

LPH 9,595 6,397 4,797 4,264 3,838 3,198 2,741

UP TO 88% EFFICIENT, HOT WATER SUPPLY BOILER WITH MODULATING FIRE 4:1 TURNDOWN

VERSATILE MULTI-VENTING CONFIGURATIONS

DIRECT-VENTING

™

SIDEWALL VENTING CONVENTIONAL

VENTING

NOTE: Maximum gas supply pressure: 11˝ W.C. natural gas, 13.8˝ propane

Minimum gas supply pressure: 4˝ W.C. natural gas, 8˝ propane

Electrical Power: 120 Volts, 60 Hertz, 30 Amps.

RECOVERY CAPACITIES