17

For protection against excessive pressures and

temperatures, a temperature and pressure relief valve must

be installed in the opening marked “T & P RELIEF VALVE”

(see Figure 15A). This valve must be design certified by

a nationally recognized testing laboratory that maintains

periodic inspection of the production of listed equipment or

materials as meeting the requirements for Relief Valves for

Hot Water Supply Systems, ANSI Z21.22. The function of

the temperature and pressure relief valve is to discharge

water in large quantities in the event of excessive

temperature or pressure developing in the water heater.

The valve’s relief pressure must not exceed the working

pressure of the water heater as stated on the rating plate.

IMPORTANT: Only a new temperature and pressure relief

valve should be used with your water heater. Do not use an

old or existing valve as it may be damaged or not adequate

for the working pressure of the new water heater. Do not

place any valve between the relief valve and the tank.

The Temperature & Pressure Relief Valve:

• Must not be in contact with any electrical part.

• Must be connected to an adequate discharge line.

• Must not be rated higher than the working pressure

shown on the rating plate of the water heater.

The Discharge Line:

• Must not be smaller than the pipe size of the relief

valve or have any reducing coupling installed in the

discharge line.

• Must not be capped, blocked, plugged or contain any

valve between the relief valve and the end of the dis-

charge line.

• Must terminate a maximum of six inches above a floor

drain or external to the building. In cold climates, it is

recommended that the discharge pipe be terminated at

an adequate drain inside the building.

• Must be capable of withstanding 250°F (121°C) without

distortion.

• Must be installed to allow complete drainage of both

the valve and discharge line.

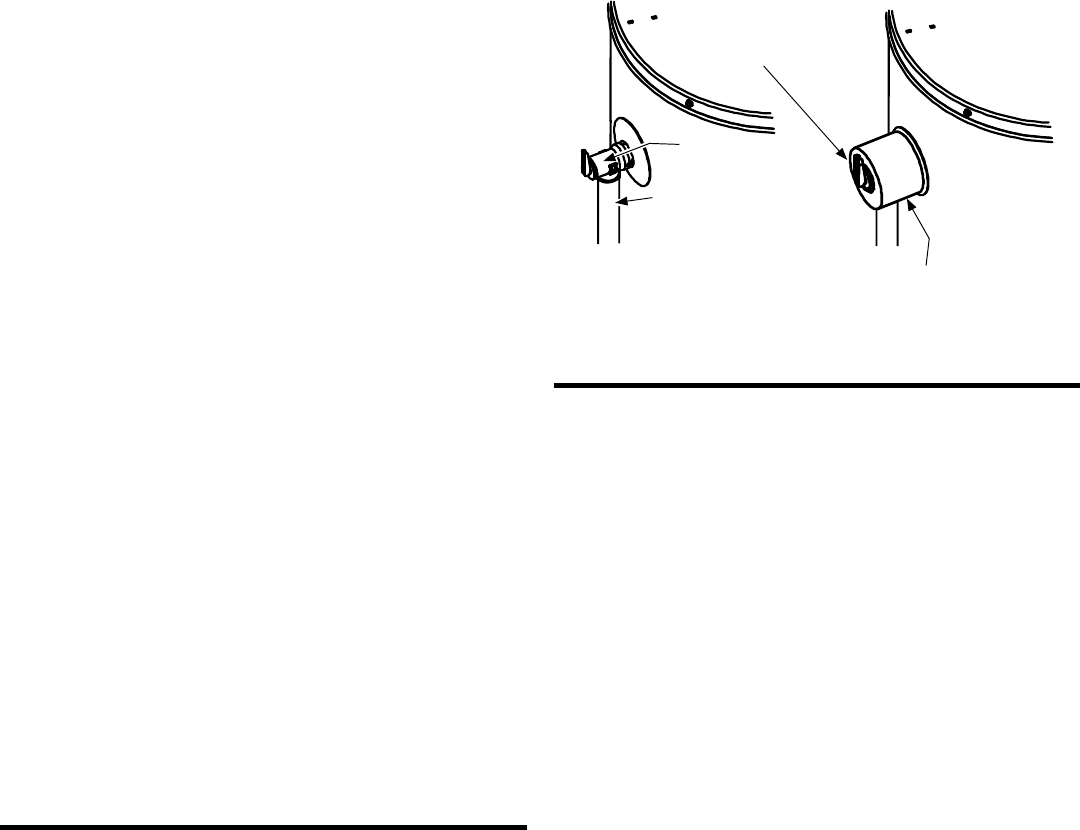

T&P Relief Valve and Pipe Insulation

1. Locate the temperature and relief valve on the water

heater (also known as a T&P Relief Valve, Figure 15B).

2. Locate the slit running the length of the insulation.

3 Spread this slit open and slip it up under the T&P Relief

Valve. See Figure 15B. Apply gentle pressure to the

insulation to ensure it is fully seated on the T&P Relief

Valve. Once sealed secure the insulation with a section

of duct tape, electrical tape, or equivalent.

IMPORTANT: The insulation or tape must not block the

discharge opening or hinder access to the manual relief

lever. Ensure a discharge pipe is installed into the T&P

valve discharge opening per the instructions manual.

4. Locate the hot water (outlet) & cold water (inlet) pipes to

the water heater.

5. Locate the slit running the length of a section of pipe

insulation.

6. Spread the slit open and slip the insulation over the cold

water (inlet) pipe. Apply gentle pressure along the length

of the insulation to ensure it is fully seated around the

pipe. Also ensure that the base of insulation is flush with

the water heater. Once seated, secure the insulation with

duct tape, electrical tape, or equivalent.

7. Repeat steps 5 through 6 for the hot water (outlet) pipe.

8. Add additional sections of pipe insulation as needed.

T&P Relief Valve Insulation

Manual Relief Lever

T&P Relief Valve

T&P Relief Valve

Drain Line

FIGURE 15B.

Combination Space Heating/Potable

Water System

Some water heater models are equipped with inlet/outlet

connections for use with space heating applications. If this

water heater is to be used to supply both space heating

and domestic potable (drinking) water, the instructions

listed below must be followed.

• Be sure to follow the manual(s) shipped with the air

handler system.

• This water heater is not to be used as a replacement

for an existing boiler installation.

• Do not use with piping that has been treated with

chromates, boiler seal or other chemicals and do not

add any chemicals to the water heater piping.

• If the space heating system requires water

temperatures in excess of 120°F, a mixing valve

or an anti-scald device should be installed per its

manufacturer’s instructions in the domestic (potable)

hot water supply to limit the risk of scald injury.

• Pumps, valves, piping and fittings must be compatible

with potable water.

• A properly installed flow control valve is required to

prevent thermosiphoning. Thermosiphoning is the

result of a continuous flow of water through the air

handler circuit during the off cycle. Weeping (blow off)

of the temperature and pressure relief valve (T & P)

or higher than normal water temperatures are the first

signs of thermosiphoning.

• The domestic hot water line from the water heater

should be vertical past any mixing valve or supply line to

the air handler to remove air bubbles from the system.

Otherwise, these bubbles will be trapped in the air

handler heat exchanger coil, reducing the efficiency.

• Do not connect the water heater to any system or

components previously used with non-potable water

heating appliances when used to supply potable water.

Some jurisdictions may require a backflow preventer in the

incoming cold water line. This may cause the temperature

and pressure relief valve on the water heater to

discharge or weep due to expansion of the heated water.