37

Operating Sequence

NOTE: The following sequence is based on a three-stage system.

1. The EMC 5000 controller has four modes of operation: Initialization,

Standby, Running, and Service. The internal CCB and FCB micros

control these modes through a sequence of steps (or States) which

are further described in the "UIM Operating Procedures" section.

2. When power is applied to the system, it enters the initialization

mode and the following automatic functions are performed:

• A. O. Smith opening screen is displayed.

• The system goes through a calibration indicated by the green

running LED blinking and then staying on; next the red service

LED and yellow standby LEDs come on, next the stage 1 service

and runnings LEDs blink ON and OFF followed by stage 2, stage

3, stage 4 and then back to stage 1, 2, 3, 4 LEDs.

• Stored values are recalled from memory.

• Configuration dipswitches are read.

• Pending faults are recalled

• Micros on all boards start running (indicated by a flashing

Yellow LED near each micro)

• Input sensors are read

• FCB's are configurated with the number of ignition trials to run.

3. After initialization is complete (approximately 10 seconds) the

system turns the green LED off and goes to the standby mode

(yellow "Standby" LED on), unless a previously stored fault has

been recalled, which will send the system into the service model

(red "Service" LED on). In standby mode the display shows

the temperature screen and in fault mode the current error

screen is displayed.

4. The system then compares the temperature read from the

controlling probe (inlet or tank) to the setpoint temperature. If

the temperature is less than the operating setpoint minus the

differential temperature and the thermostat input is closed then

a call for heat is established and the system shifts to the run

mode (green "Running" LED turns on).

5. The heating sequence begins by applying power to the pump

and, if selected, the powered vent and the IRI gas valve.

6. After a few seconds the blowers are turned on for 30-second

pre-purge period of combustion chamber.

7. The stage one igniter is turned on.

8. After the igniter has reached a minimum of 2.8 amps, the gas

valve is energized to allow gas flow to burners.

9. After an additional one second, the system checks the status of

the flame through the flame rod (sensor). If the flame is not

verified within 4 seconds, the gas valve is immediately shut off

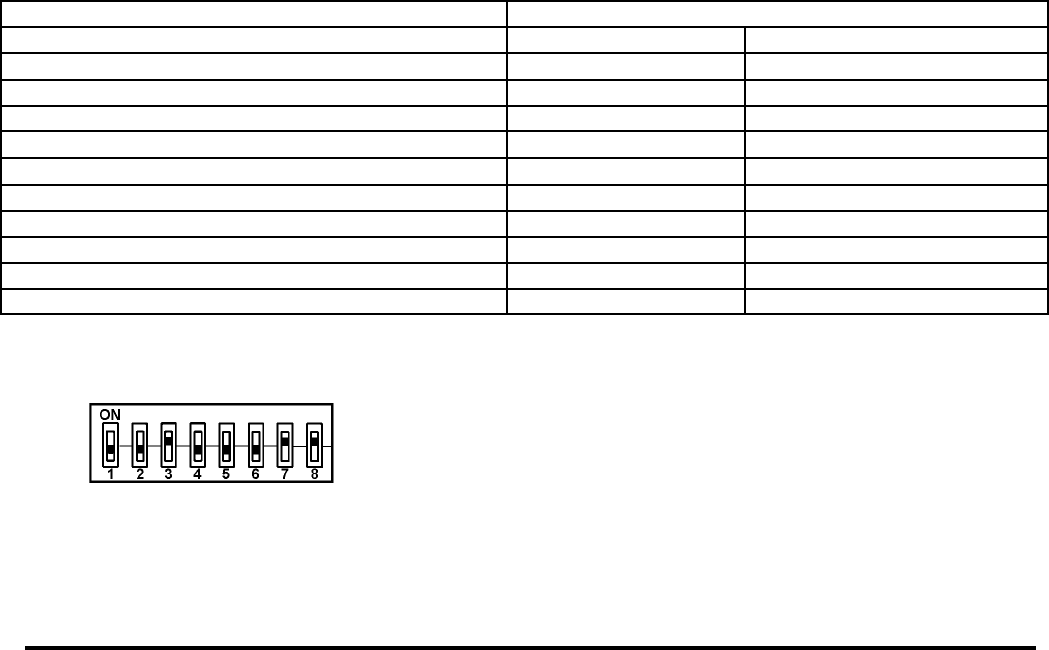

FCB: Eight-Position Dipswitch

The first three switches are similar to the switch setup of SW2 on the CCB. The remaining five switches are required for the function

of igniter, blower, flame detection, and to address the firing stage. NOTE: When switch 5 is set to OFF (no blower), switch 3 (blower

speed) is ignored.

Dipswitch Function: Dipswitch Position

Switch 1: Spare:

Switch 2: Hi Gas pressure switch: On = Yes Off = No

Switch 3: Number of Blower Speeds: On = 1 speed, Off = 2 speed

Switch 4: Igniter used: On = Yes, Off = No

Switch 5: Blower used: On = Yes, Off = No

Switch 6: Flame Checked: On = Yes, Off = No

Switch 7 & 8. Stage selection: 7 8 Stage #

Off Off Not allowed

On Off 2

Off On 3

On On 4

*When switch 5 is in off (no blower) position, switch 3 (blower speeds) is ignored.

Example of Dipswitch configuration:

No High Gas, 1 blower speed, no igniter, no blower,

flame not checked, stage 4.