Plunger Pumps

Operating Instructions and Parts Manual RK Series Pumps

First Choice When Quality Matters

NORTH

AMERICA

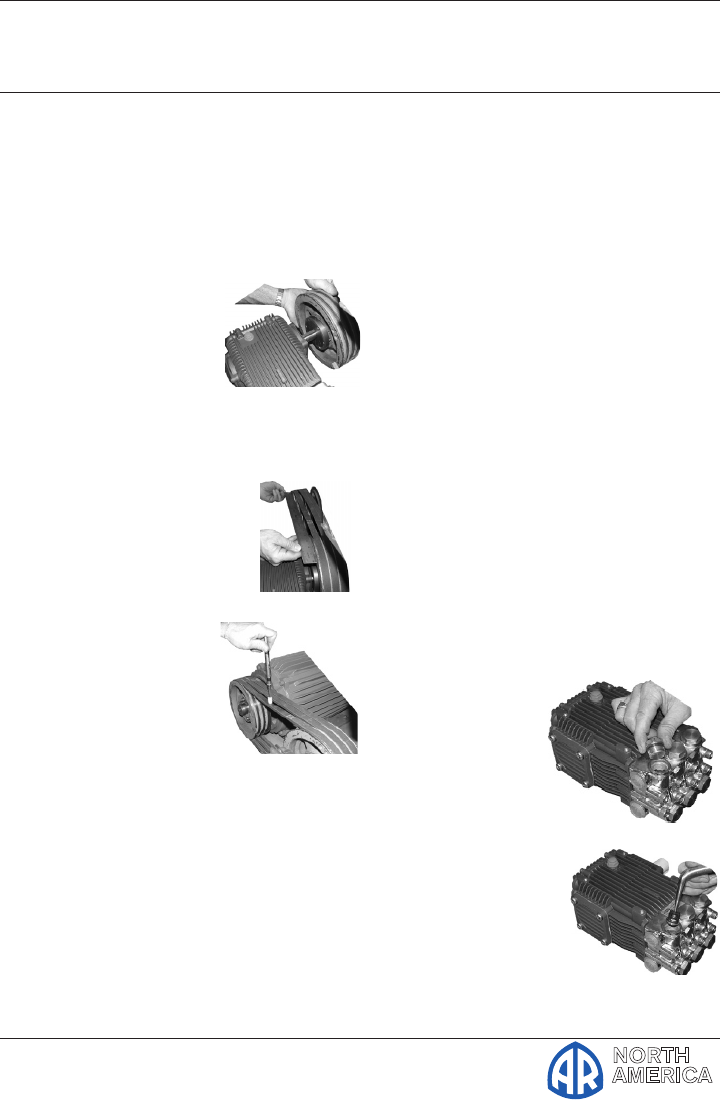

Figure 7

Figure 11

Figure 10

Installation (continued)

9. Open the spray gun to purge the

system of any air.

10. Start the engine.

11. Adjust the engine speed and

unloader valve.

Belt Drive Systems

1. Mount the pump

securely to the base

plate. (See Figure 7)

For new installation

a mounting rail kit

is required, refer to parts

breakdown.

2. Install the pump pulley on the

crankshaft. It should be

as far onto the shaft as

possible.

3. Align the pulleys so they

are in line. (See Figure

8)

4. Use a belt tension

gauge to assure

proper tension

(too much tension

can cause bearing

failure or damage

the belts as well as

cause other problems).

(See Figure 9)

5. Installation complete.

Winter or Long Time Storage

1. Drain all of the water out of the

pump.

2. Run a 50% solution of a RV or

non-toxic/biodegradable antifreeze

through the pump.

3. Flush the pump with fresh water

before the next use.

4. In freezing conditions failure to

do this may cause internal pump

damage.

5. For long periods of storage in

non-freezing areas the solution

will keep the seals and O-rings

lubricated.

Service Pumps

Servicing the Valves

The inlet and discharge valves in this

series pumps are all the same. The

valves are located under the six 24mm

hex plugs. The inlet valves are located

on the lower row and the discharge

valves are located on the top row of the

pump head.

Tools required: 24mm socket, ratchet,

needle nose pliers, mechanics pick and

torque wrench.

Valve Removal:

1. Remove the valve cap.

2. Inspect the

valve cap O-

ring for any

damage, replace

if necessary. (See

Figure 10)

3. Use the needle nose

pliers to remove the

valve. (See Figure

11)

Figure 8

Figure 9