12 English

EN

7

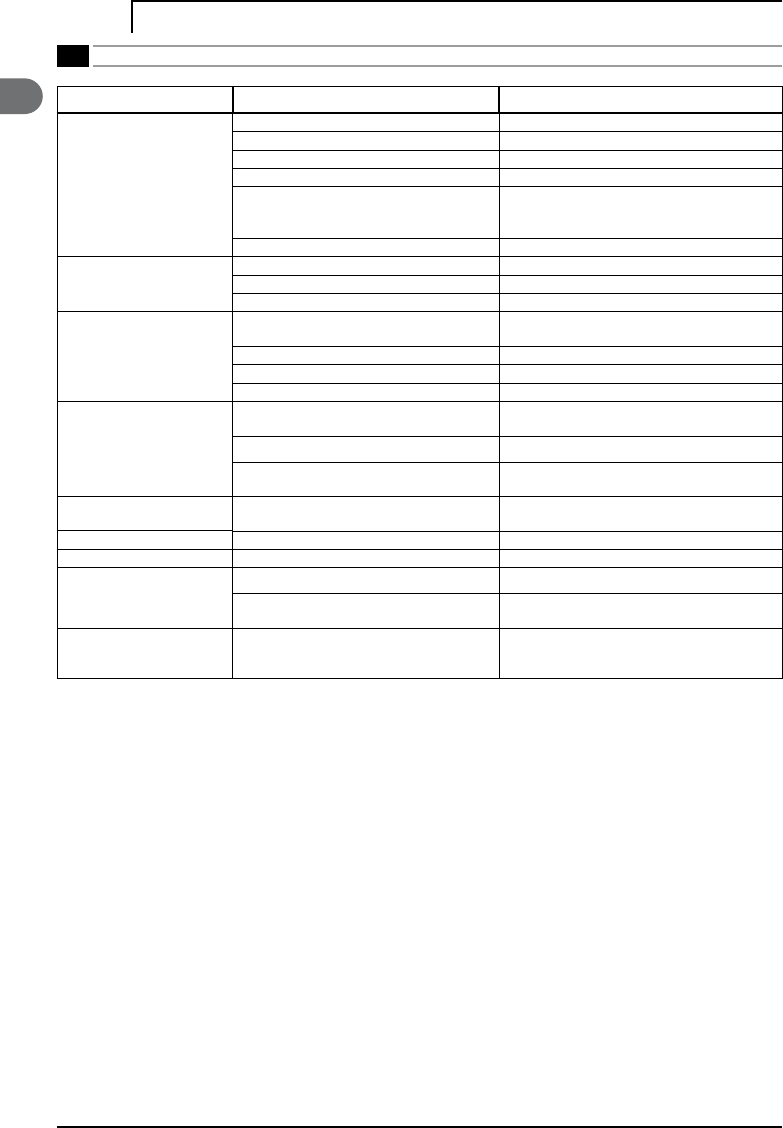

TROUBLESHOOTING

Problem Possible causes Remedy

Pump does not reach working

pressure

Nozzle worn Replace nozzle

Water filter fouled Clean filter (fig.5)

Water supply pressure low Turn on water supply tap fully

Air being sucked into system Check tightness of hose fittings

Air in pump

Switch off the appliance and keep depressing and releas-

ing the gun trigger until the water comes out in a steady

flow. Switch the appliance back on again.

Adjustable nozzle not positioned correctly Turn the adjustable nozzle (E) (+) (fig.3)

Pressure drops during use

Water intake from external tank Connect appliance to the mains water supply

Intake water too hot Reduce temperature

Nozzle clogged Clean nozzle (fig.5)

Motor “sounds” but fails to start

Insufficient power supply

Check that the voltage of the mains power supply line is

the same as that on the plate (fig.2)

Voltage loss due to use of extension cable Check characteristics of extension cable

Appliance not used for a long period of time Contact your nearest Authorized Service Centre

Problems with TSS device Contact your nearest Authorized Service Centre

Motor fails to start

No electrical power

Check that the plug is firmly in the socket and that the

mains voltage supply is present (*)

Problems with TSS device Contact your nearest Authorized Service Centre

Appliance not used for a long period of time

Using the tool (L) unjam the motor from the hole at the

rear of the appliance (in models with this feature) (fig.5)

Water leakage Seals worn

Have the seals replaced at your nearest Authorized

Service Centre

Appliance noisy Water too hot Reduce temperature (see technical data

Oil leakage Seals worn Contact your nearest Authorized Service Centre

TSS versions only:

motor starts

even with gun trigger is released

Nozzle clogged Clean nozzle (fig.5)

High pressure system or pump hydraulic circuit not

watertight

Contact your nearest Authorized Service Centre

TSS versions only:

no water deliv-

ery when gun trigger is depressed

(with supply hose connected)

Nozzle clogged Clean nozzle (fig.5)

If the motor starts and does not restart during operation, wait 2-3 minutes before repeating the start-up procedure (overload cutout has been tripped).

If the problem recurs more than once, contact your nearest Authorized Service Centre.