7

TUBINGINSTALLATION

Inspectalltubingregularlyandreplaceifanysignofdeteriorationoccurs.Alwayswearsafety

glassesandprotectiveclothingwhenworkingwithchemicals.Seechartbelowforproper

tubinginstallationprocedureforyourunit.

*90_‐002through90_‐014 ProcedureA(below)

90_‐023through90_‐049 ProcedureAorB(page6or8)

90_‐058through90_‐282 ProcedureAorC(page6or9)

*WARNING:MODEL907‐002,907‐007,907‐014,908‐002,908‐007and908‐014GEARTRAINS

CANBEDAMAGEDIFDRIVESHAFTISROTATEDBYHANDFORTUBEINSERTION.

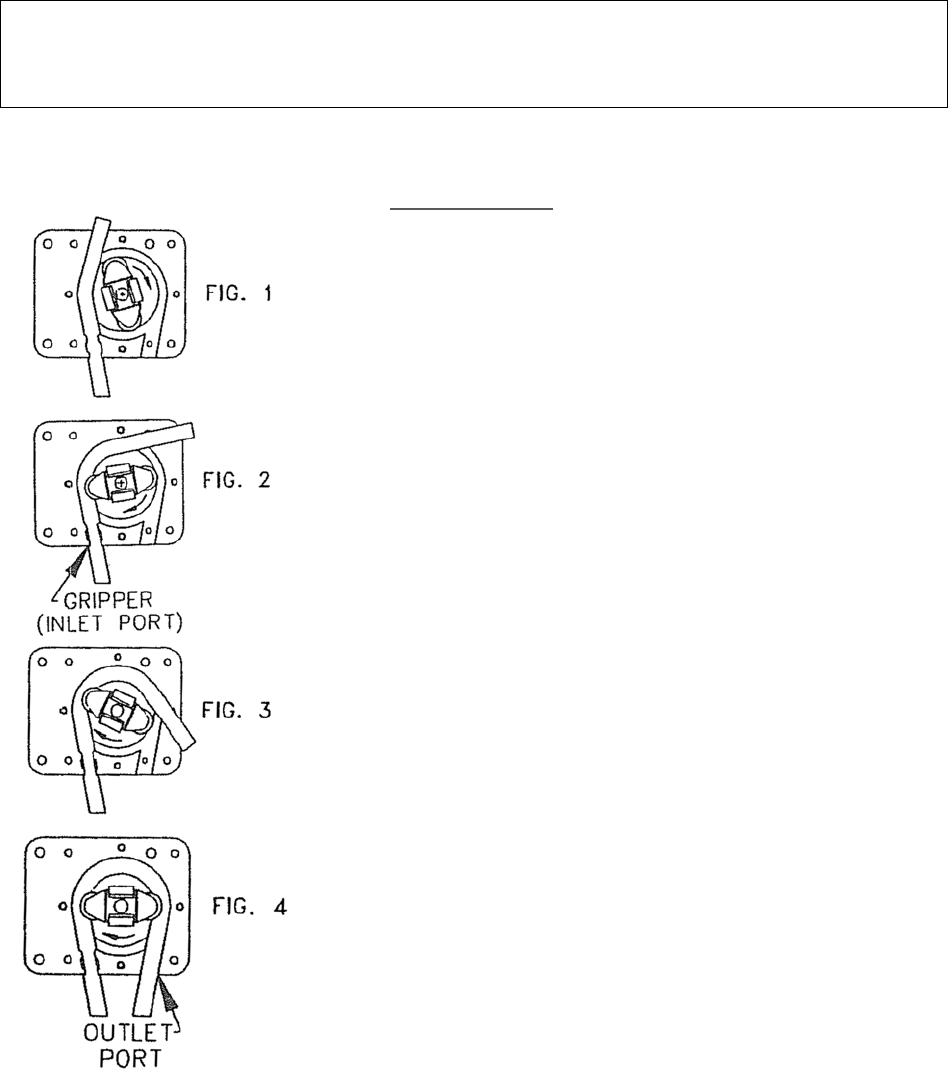

PROCEDUREA

(Ifunitisnewstartwithstep#6.)

1. Disconnectpowertothepump.

2. Disconnectthesuctionanddischarge

tubingfromthepumptubing.

3. Removefourscrewsandpumpcover

frompumphead.

4. Pulloutoldpumptubinganddiscard.

5. Cleanrollerrace,removingand

particlesthatcoulddamagetubing.

6. Connectpowerandrunatslowest

speeduntilrollerbracketassemblyis

inpositionasshowninfigure1.

7. Pushnewtubingintoinletport,

anchoringtubingingrippers.Ifusing

a9”pieceoftube,11/2”shouldbe

extendedoutsideofinletport.(figure

2)

8. Continuetorunatslowestspeed

carefullyfeedingtubeintoraceasthe

rollersturn.(figure3)

(Keepfingersawayfromrollers).

9. Inserttubingintooutletport(figure

4)andreplacecover.