-2-

1. TABLE OF CONTENTS

2. Pre-Installation Checklist .................................................

2

3. Required Components and Accessories Checklist .........

3

4. WH-7 & 9 Classic Series Piping Installation ....................

4

5. Top Down™ TD-Series Piping Installation ......................

6

6. Ready-To-Run RTR-Series Piping Installation ................

8

7. WHS Premier Series Piping Installation ........................

10

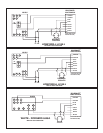

8. Wiring All Smart Control™ Models ...............................

12

9. Wiring All Dial Control Models (Except RTR Models) .........

20

10. Wiring All Ready-To-Run (RTR) Models .......................

23

11. Startup Procedure For All Models ................................

25

12. Setting the Smart Control™ ..........................................

26

13. Troubleshooting .............................................................

27

14. Replacement Parts ........................................................

28

15. Cleaning the BoilerMate

®

Heat Exchanger ...................

29

16. General Safety Information ...........................................

30

2. PRE-INSTALLATION CHECKLIST

IMPORTANT STEPS AND DECISIONS REQUIRED BEFORE INSTALLATION

M THIS PRODUCT MUST BE INSTALLED AND

MAINTAINED BY A LICENSED PROFESSIONAL. IN

ADDITION TO THE INSTRUCTIONS IN THIS MANUAL,

FOLLOW ALL APPLICABLE LOCAL AND STATE CODES

OR IN THE ABSENCE OF SUCH CODES, THE CURRENT

EDITIONS OF THE NATIONAL PLUMBING CODE AND

THE NATIONAL ELECTRIC CODE.

M DRIP PAN AND DRAIN: This appliance should not

be installed in an area where leakage of the tank or

connections can result in damage to the area adjacent

to the appliance or to lower floors of the structure.

When such locations cannot be avoided, a suitable

drain pan, adequately drained and kept clear, must be

installed under the appliance.

M CAUTION: Determine whether your water is corrosive

or acidic, and that there are no suspended solids,

toxic or other substances or abnormally high chlorine

levels in the water that could damage or affect the

BOILERMATE

®

or the rest of your plumbing system.

USE GLYCOL ONLY WITH

DOUBLE-WALLED HEAT EXCHANGER

MODELS. Glycol is a hazardous substance. To avoid

seepage or leakage of glycol to surfaces where

humans or animals can ingest it, use glycol only in

double-walled units, so that any leaks will most likely

be released to the atmosphere. However, a leak to a

surface area may still occur, so any use of glycol must

be monitored closely and humans and animals should

be protected from contact with the unit.

Do not connect the BOILERMATE

®

domestic supply with baseboard

or other space heating units or elements. Any

contaminants in the baseboard units will contaminate

the potable water in the BOILERMATE

®

and also

adversely affect its performance.

M Wiring Options. Select either a Non-Priority or Priority

System:

Two options are available when wiring the controls of the

BOILERMATE

®

in the space heating system (boiler and

distribution elements).

1. Non-Priority System - The controls of the

BOILERMATE

®

must be wired as a separate heating

zone with a standard zone valve or a separate

circulator dedicated to the BOILERMATE

®

“zone”.

NOTICE: In this non-priority option, the BOILERMATE

®

will be supplied just as another zone. This means that if all

space heating zones call for hot boiler water at the same

time, the BOILERMATE

®

may not be supplied with enough

hot boiler water to “recover” adequately. The delivery of

domestic hot water will be diminished. In many, but not all

cases, this is not a problem because the routine oversizing

of boiler output is adequate for both loads.

2. Priority System - Under this wiring option the

BOILERMATE

®

will be supplied before space heating.

In limited circumstances, space

heating can be lost in the home in

this priority mode. Any demand for space heating is

postponed until the BOILERMATE

®

has reached its set

temperature. This delay in supplying the space heating

zones is usually not noticed by the inhabitants of the

living spaces. However, in the event of certain

malfunctions such as circulator or thermostat failure,

space heating could be delayed indefinitely. If

undetected and uncorrected, freezing damage to piping

could result.

M Select Circulator versus Zone Valve

The flow of hot boiler water to the BOILERMATE

®

can

be controlled with either a motorized zone valve or a

circulator.

1. Separate circulator. The recommended way to

provide adequate flow through the BOILERMATE

®

heat exchanger is to use a separate dedicated

circulator with a minimum flow rate of 5 gpm. This

option may be used even though the heating system

utilizes zone valves.

2. Zone valve (system flow of 4-8 gpm). If a zone valve

is to be used, a minimum flow rate of 5 gpm with all

zones in use is required. A full-port zone valve should

be used.

M All installations require a low-water cut-off or automatic fill

valve on your boiler system to reduce the risk of boiler water

loss.

M Steam boiler installations require a low-water cut-off which

is also required by most codes.

M Installation of a vacuum breaker is required to prevent

damage to the BOILERMATE

®

when drained. There must

be no valves installed between the vacuum breaker and

BOILEMATE

®

.