-2-

Utilizing the Maximum Capacity of Full

Acceptance Well-X-Trol

®

s Series 400,

420, 440 and 450

When used with conventional pressure ranges,

these Well-X-Trol models use only a fraction of

their maximum capacity.

For Example:

A WX-423 with a total volume of (275)

gallons will accept the following:

at 30/50 – (85) gallons or 30.9%

at 40/60 – (74) gallons or 26.7%

By using the maximum acceptance of series 420

and 450 Well-X-Trol

®

, you can replace very large,

cumbersome galvanized tanks.

Let’s Compare:

A 900 gallon galvanized tank is (48″) in diameter;

(168″) long, and weighs approximately (10,000)

pounds when filled with water.

Aside from initial cost, the cost of rigging and handling

a tank of that size; (providing adequate support and

the cost of space required) significantly adds to the

overall installation cost.

Requires Air Control

Since at the higher pressures, the galvanized

tank will waterlog at an accelerated rate, some

provision must be made to maintain the required air

cushion. This means the cost of an air compressor

or other means of recharging must be added to the

installation.

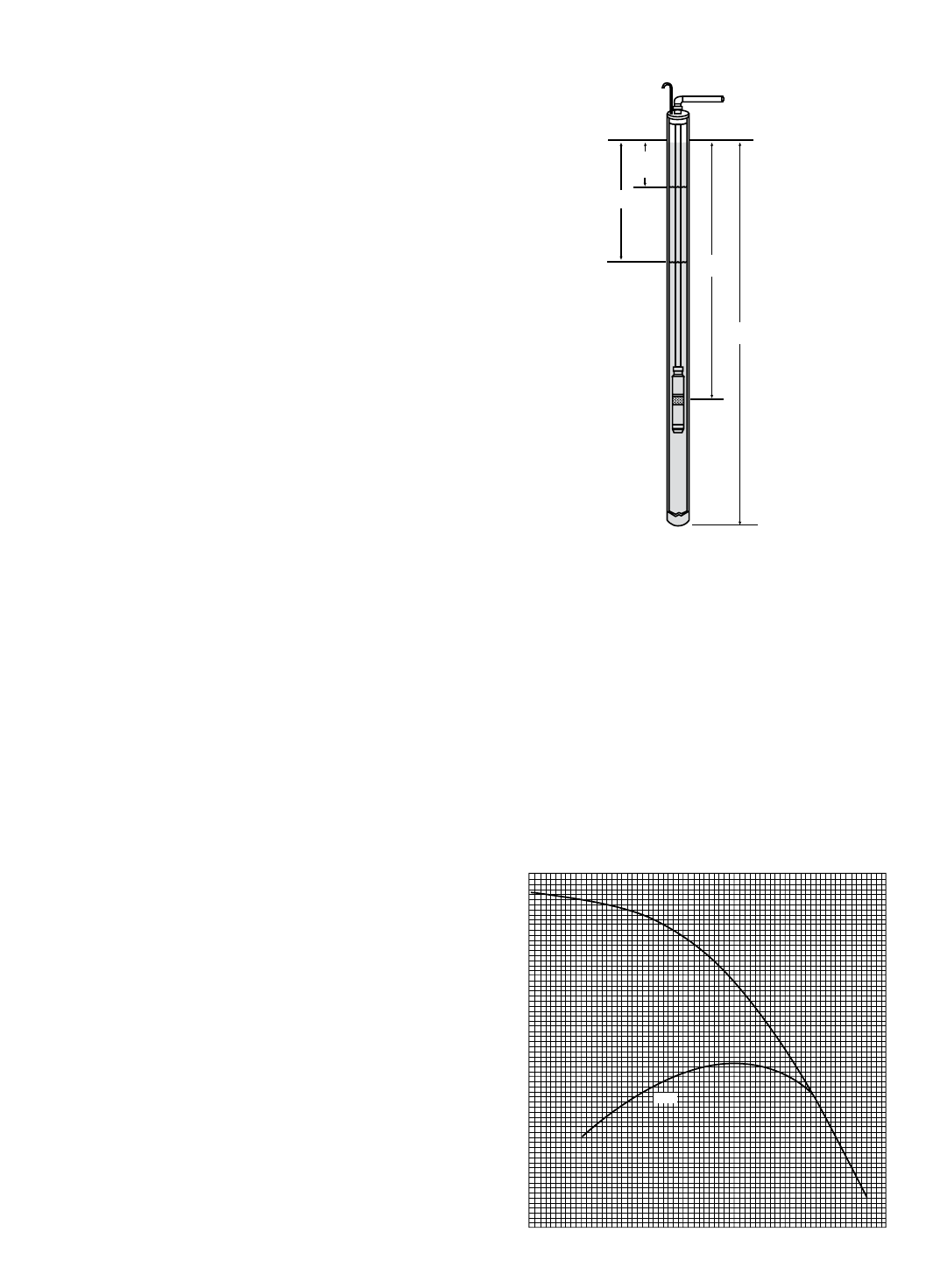

On the Other Hand

The WX-423 has a total volume of only (275)

gallons; is only (36″) in diameter; and (84″) high.

When filled with water (to the 65% maximum

acceptance) it only weighs (1489) pounds.

It can be easily handled by two men, requires no

support structures and occupies a fraction of the

space of the galvanized tank. Since the Well-X-

Trol

®

’s air cushion is sealed-in, there is no need for

external air compressors or control devices.

If we can use the maximum acceptance of the 420

and 450 Series Well-X-Trol

®

, we can service much

larger jobs…with large pumps, without paying the

penalty of higher installation and maintenance costs.

Step One – Determine the Best Operating

Pressure Range – Pump Cut-In (P2) to

Pump Cut-Out (P3):

The first thing we must do in sizing the bladder is to

determine the best pressure range that will achieve

maximum acceptance.

. We can be accurate by letting the pump tell us at

which maximum range it will operate best.

If we look at the pump curve for the pump which is

to be installed…we can easily determine the pump

cut-in pressure (P

2

) and pump cut-out pressure (P

3

)

that will give us the widest range.

GROUND LEVEL

STATIC

WATER

LEVEL

PUMPING LEVEL

OR LIFT

PUMP

DEPTH

WELL

DEPTH

240 FT.

(In example)

36"

84"

WX-423

1489 LBS.

275 GALS.

TOTAL VOLUME

48"

AIR COMPRESSOR

900 GALLON

GALVANIZED TANK

168"

10,000 LBS. (WITH WATER)

0

100

200

300

400

500

600

700

20 40 60 80 100 120 140

20

40

60

80

TOTAL HEAD IN FEET

CAPACITY IN GPM

EFFICIENCY %

EFF.