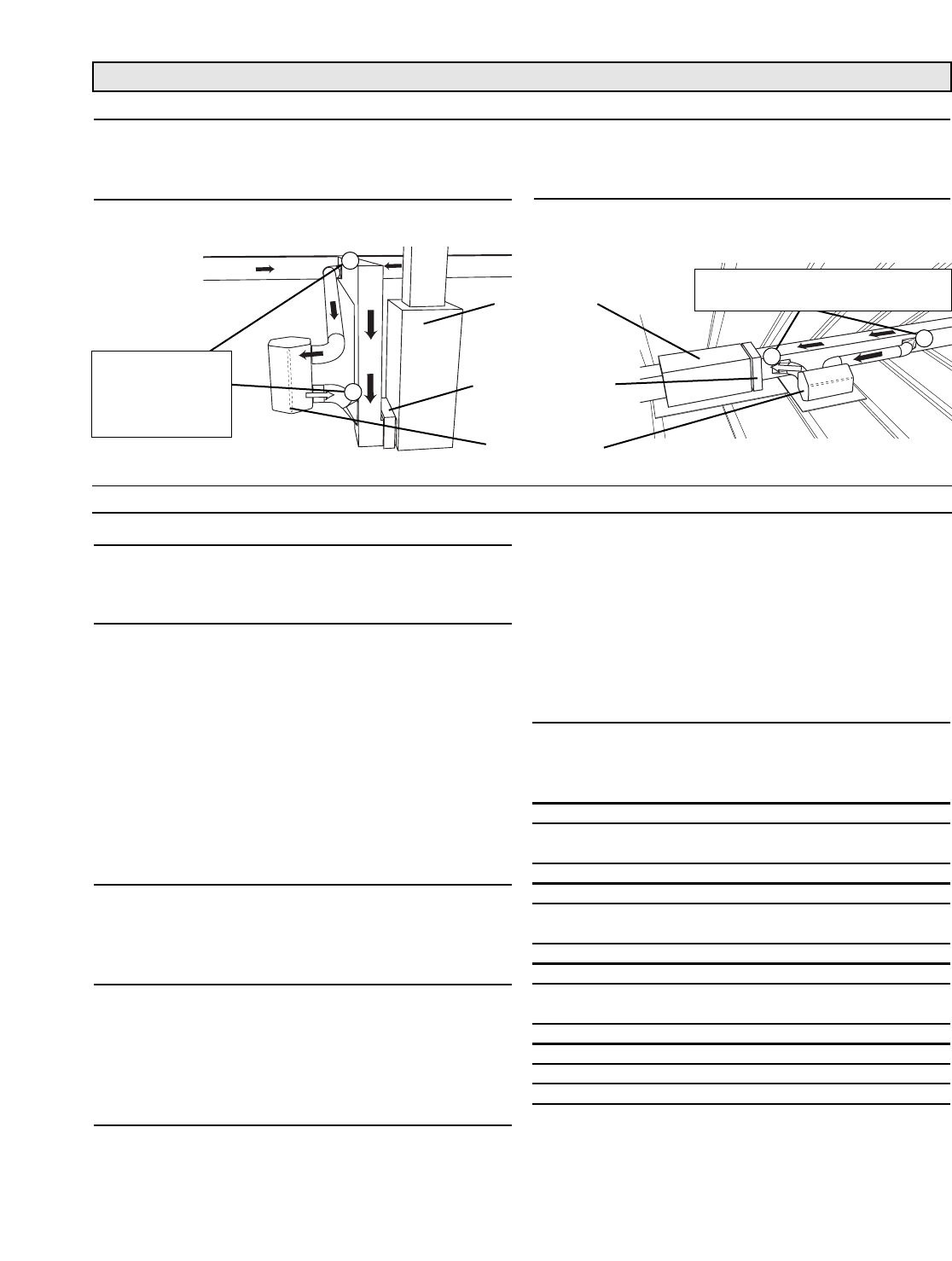

Typical Return to Return Application

For homes with horizontal forced air handler/furnace

systems. (Air handler/furnace is shown in an typical

attic. See figure 7.)

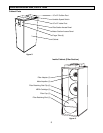

Typical Return to Return Application

For homes with upflow forced air handler/furnace sys-

tems.(Air handler/furnace is shown in a typical base-

ment. See

Figure 6.)

9

Dealer Installation Instructions

Forced air handler/furnace systems:

The HEPA system should be installed as a bypass system, with part of the return ducted into the HEPA system. The

filtered air is then rerouted back into the return air, and continues through the system to be heated/cooled.

Figure 14.

Figure 15.

Preparation:

Here are some things to consider as you decide where

to install the HEPA system.

Location:

• Make sure there is room to open the HEPA filter

access panel for filter changes/inspections.

• Keep the HEPA system in a location where you

can still access the air handler/furnace filter.

• Keep the HEPA system away from possible water damage.

•Vibration pads will reduce vibration for installations

where the unit is placed on the floor.

• Install HEPA System on floor or suspended platform.

If the unit is suspended, screws must not penetrate

through the cabinet. Make sure that you have the

proper chains/straps/joists and equipment to keep

unit secure.

Intake (Marked as ‘Air In’ on unit):

• Intake ducts should be installed upstream of any

humidifiers and be installed on the main return.

• Intake duct should be installed at least 6 ft. away

from the outflow duct on the main return.

Outflow (Marked as ‘Clean Air Out’ on unit):

• Outflow duct should be installed as close to the air

handler/furnace inlet as possible but not directly

into the return air elbow of the main return.

• If the unit is being installed independently of any

other system, room diffusers are recommended to

help distribute airflow evenly in the occupied space.

Ducting:

• If HEPA system is installed where inlet and outflow

collars face down, metal elbows must be connected

to both inlet and outflow collars.

• Each connection must be sealed with aluminum

tape or mastic, including all take offs.

• Installed duct runs should be as straight as possi-

ble (if the duct runs are too long, reduced CFM

may result).

• If duct is exposed to unconditioned air, externally

insulated flex duct is highly recommended.

• Externally insulated flex duct can also be used for

noise reduction purposes.

• For best indoor air quality, do not use ductboard or

fiberglass inside of ducts.

Electricity:

• The unit must be plugged into a grounded 120V,

60Hz outlet.

Required Materials for Installation of Unit:

Items for 2500HV & 4000HV

Flex or rigid duct 6” round

(length as required)

Takeoffs Two 6”

Items for 6000V

Flex or rigid duct 10” round & 8” round

(length as required)

Takeoffs One 10” & One 8”

Items for 6500, 8500 & 10000

Flex or rigid duct 10” x 12”

(length as required)

Takeoffs Two 10”x12”

All Models

Aluminum tape or mastic as required

Misc. hanging materials - field provided

NOTE: Be sure to review ‘Rules for Safe Installation

and Operation’ on page 1 of this document before

start-up of this unit.

A

A

B

B

Air Handler/

Furnace

Air

Handler/Furnace

Filter

HEPA System

NOTE: This filtration system is an ADDITIONAL filter, and does NOT replace the existing air handler/furnace system filter.

Distance between

A and B should

be 6' to 16' for

best results

Distance between A and B should

be 6' to 16' for best results