12

DX 845 W / DX 865 / DX 985 / TitanEnergy / TitanEnergy X

GB

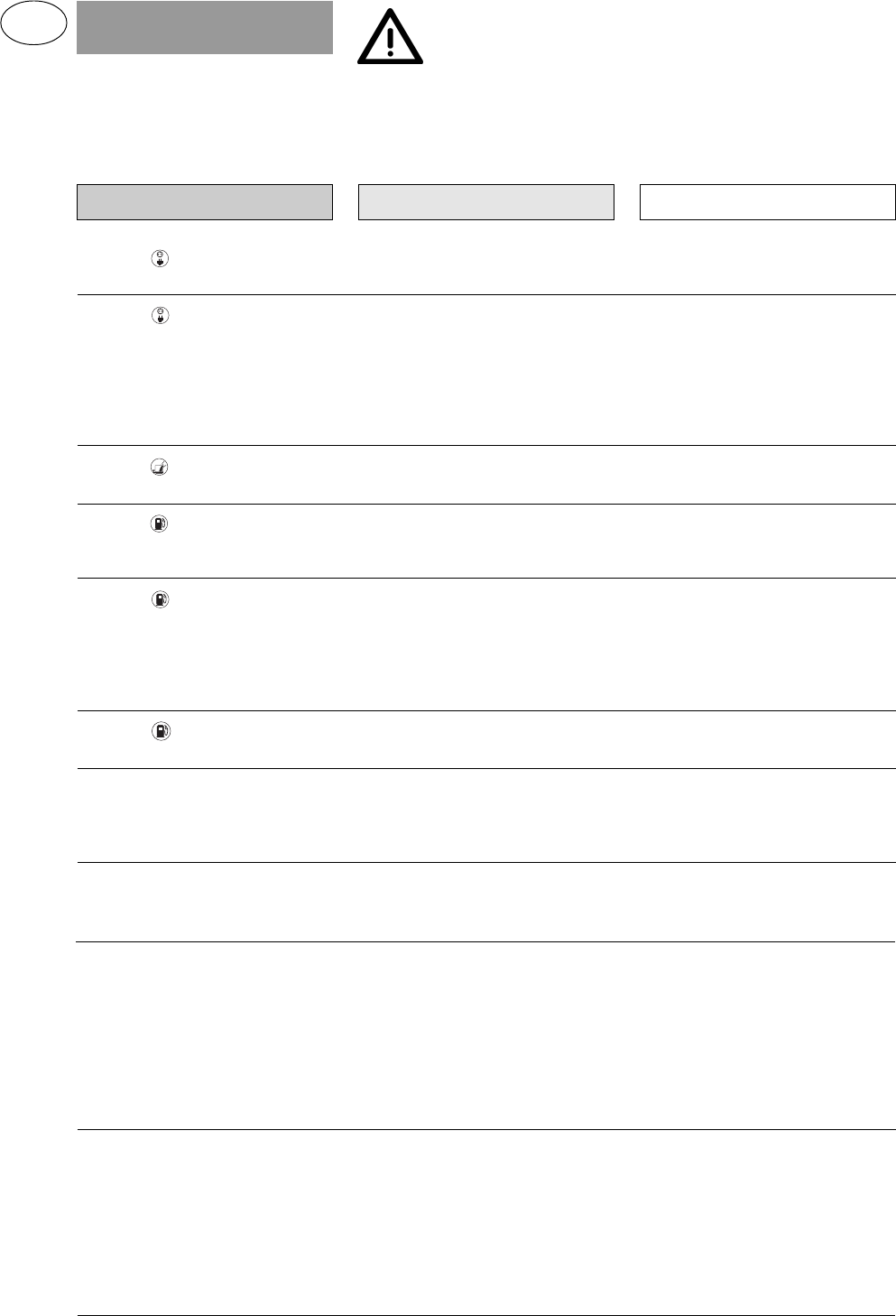

CAUSE REMEDY

‡ Display does not light up,

machine does not start

‡ Display

flashes rapidly (5x per

second), motor has cut out and will

not start again

‡ Display

is lit continuously

‡ Display

is lit continuously

‡ Display

flashes slowly (1x per

second)

‡ Display

flashes rapidly (5x per

second), burner will not start again

‡ Machine stops and starts intermit-

tently with the trigger gun open

‡ Machine stops and starts intermit-

tently with the trigger gun closed

‡ Pressure too low

‡ Cleaning agent is not drawn in

> Fault in the mains cable

> Motor overheated

> Anti-Stone concentrate container

empty

> Fuel tank empty

> Contamination or water in fuel

> Burner sooted

> Inadequate water inlet

> Cleaning agent tank empty

> Pressure and volume controller or

VarioPress trigger gun set too low

> Flame sensor sooted

> Fault in ignition or fuel system

> High-pressure nozzle soiled

> Machine scaled

> Trigger gun leaking

> High-pressure hose, high-pressure

screw fitting or pipework leaking

> Cleaning agent tank empty

> High-pressure nozzle worn

> Pressure and volume controller or

VarioPress trigger gun set too low

> Filter in water inlet clogged

> High-pressure pump drawing in air

> Suction or pressure valve of high-

pressure pump soiled or defective

> Cleaning agent tank empty

> Sludge in cleaning agent tank

> Suction valve at cleaning agent

inlet soiled

ð Have electrical connection checked

ð Clean or replace clogged high-

pressure nozzle

ð Set the VarioPress control knob

on the trigger gun to a higher

pressure

ð Possible phase failure; have

electrical connection checked

ð Top up anti-scale concentrate

container

ð Top up fuel tank

ð Clean fuel tank and pipework

ð Have burner setting checked

ð Use water hose with at least 1/2"

diameter, clean filter in water inlet

ð Top up cleaning agent tank

ð Set pressure and volume controller

or VarioPress control knob on the

trigger gun to a higher pressure

ð Remove and clean

ð Call service technician

ð Clean or replace high-pressure

nozzle

ð Descale according to the instruc-

tions

ð Inspect the trigger gun

ð Retighten screw fittings, replace

high-pressure hose or pipework

ð Top up cleaning agent tank

ð Replace high-pressure nozzle

ð Set pressure and volume controller

or VarioPress control knob on the

trigger gun to a higher pressure

ð Clean filter

ð Repair leaks

ð Clean or replace valves

ð Top up cleaning agent tank

ð Clean cleaning agent tank

ð Remove suction valve and clean or

replace

TROUBLESHOOTING

Before working on the machi-

ne, remove the mains lead

plug and depressurise the

machine.

1)

Option / model variants

FAULT