INSTALLATION OF A STANDARD WALL

PUSH BUTTON

If desired, a standard wall push button may be installed

and connected to your operator. A standard wall push

button is not included in your hardware package, it can

be purchased from your professional installing dealer or

a door bell button [without light] can be substituted.

The operating parameters for the standard wall push

button are outlined on a page that follows to see if that

mode of operation is right for you. The Super Station is

included with this operator and the manufacturer rec-

ommends its installation as the Super Station will pro-

vide full control over the garage door at all times.

STEP 1: After determining a suitable location,

usually near the access door and

at least 5 feet above

the floor to prevent use by children, use the standard

wall push button as a guide to mark the mounting holes.

Drill holes for drywall anchors or screws. NOTE: Do

not mount directly to masonry walls. Use backer board.

STEP 2: A length of 2-conductor, #22 gauge wire (or

heavier) is required to connect the standard wall push

button to the garage door operator. Strip approximately

2” of the wire jacket from one end and 1/2” of

insulation from each wire. Carefully connect one wire

to each of the two terminals. Carefully tuck the loose

wires into the case and mount the unit using appropriate

screws.

STEP 3: Run the wire from the standard wall

pushbutton to the operator, supporting it at 18” intervals

with suitable staples. Leave a sufficient length to make

the necessary connections to the operator terminal strip.

WARNING: SOME LOCAL BUILDING CODES

DO NOT ALLOW SURFACE WIRING. BE SAFE

AND CHECK WITH YOUR LOCAL BUILDING

INSPECTOR FIRST.

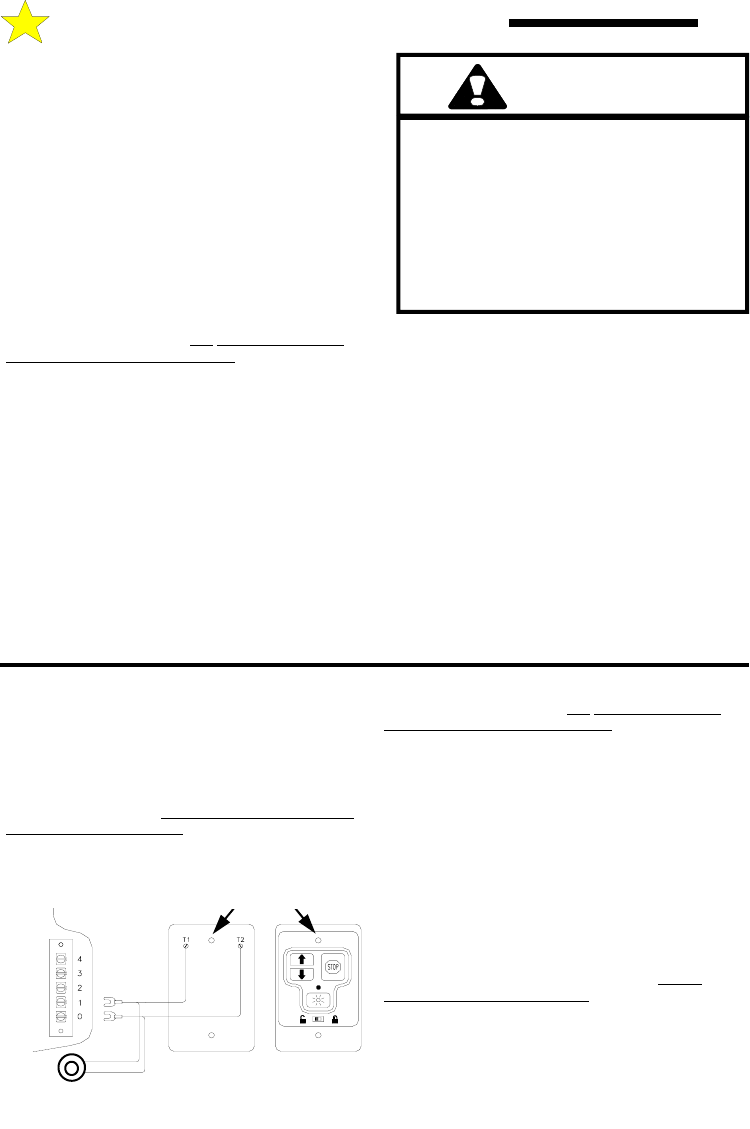

STEP 4: Ensure power is OFF to the operator or

disconnect the power from the operator. Strip

approximately 4” of jacket from the end of the wire and

1/2” insulation from each wire. Connect to terminals 0

and 1 as shown in the illustration below. Support the

wire near the operator with wire ties.

Step 5: Install the Control Button Warning Label

supplied with your opener near the standard wall push

button (see illustration next page).

WARNING

A CHILD OPERATING THE DOOR

CONTROLS RISKS INJURY — OR DEATH

— TO HIMSELF (HERSELF) AND OTHERS.

DO NOT ALLOW CHILDREN TO OPERATE

ANY DOOR CONTROLS.

MOUNT THE PUSHBUTTON AT LEAST 5

FEET FROM THE FLOOR, OUT OF REACH

OF CHILDREN.

INSTALLATION OF THE SUPER STATION

The Super Station (Deluxe Wall Pushbutton Station) is

a 7 function station designed to work with and

maximize the functionality of your garage door opener.

Connection to any other opener may damage the opener

and/or the Super Station. Only connect one Super

Station to each opener. Do not connect more than one

Super Station to an Opener.

STEP 1:

After determining a suitable location,

usually near the access door and

at least 5 feet above

the floor to prevent use by children, use the Super

Station as a guide to mark the mounting holes. Drill

holes for drywall anchors or screws. NOTE: Do not

mount directly to masonry walls. Use backer board.

The Super Station is also designed to be mounted

directly to a standard single electrical box.

STEP 2: A length of 2-conductor, #22 gauge wire (or

heavier) is required to connect the Super Station to the

garage door opener. Strip approximately 6” of the wire

jacket from one end and 1/2” of insulation from each

wire. Carefully connect one wire to each of the two

terminals indicated, noting which color is connected to

which terminal. Tighten screws, being careful that no

wires are allowed to touch any other terminal or any

other conductive part of the circuit board. Do not

overtighten the terminal screws.

STEP 3: Push the wire jacket into one of the two

notches provided at the ends of the housing, allowing a

maximum of 1/8” inch of the jacket inside the case (too

much will make mounting difficult). Carefully tuck the

loose wires into the case and mount the unit using the

screws provided.

BACK

STANDARD WALL

PUSH BUTTON

108387

SUPER STATION

DELUXE WALL PUSH

BUTTON

MOUNTING

HOLES

CONTROL AND AUXILIARY EQUIPMENT

10