EB120 Advanced Ethanol Boiler

11

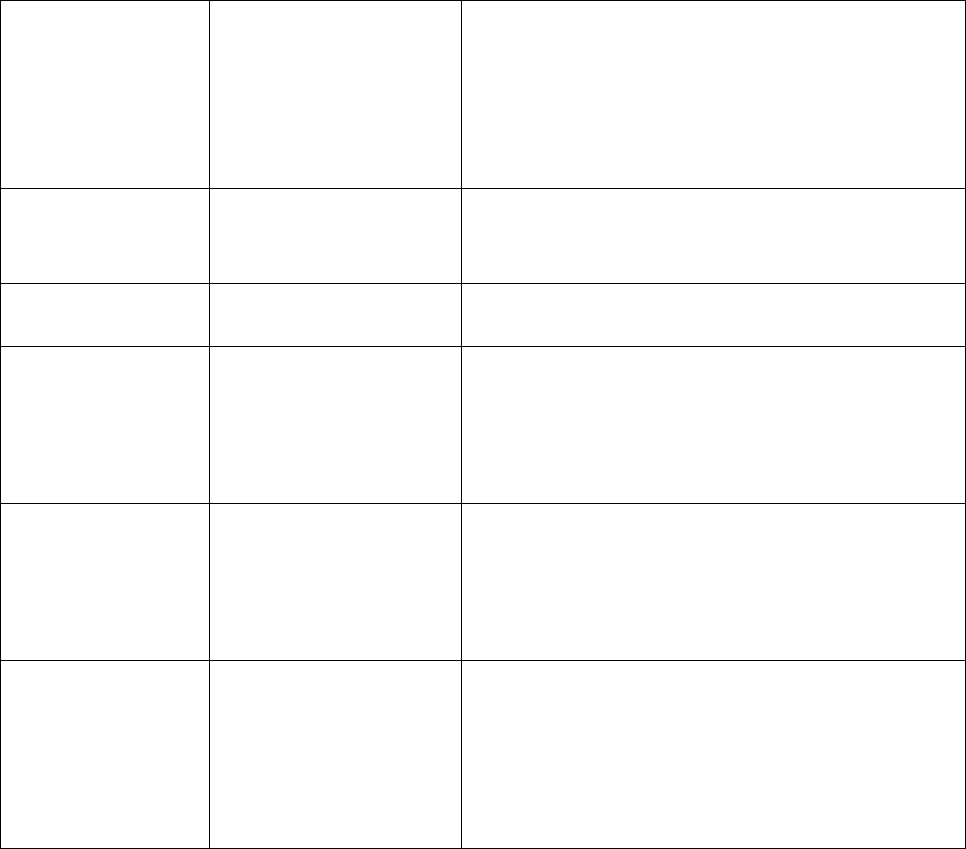

control panel is

normal, and

indicator LED for

heating is on, but

there is no steam

output

1. Main circuit board

2. Relay circuit board

3. Heating elements

* Change main circuit board

* Change relay circuit board

* Change heat elements

Temperature

displays “LC”

Check:

Beer level probe

connection

Check connection or change beer level probe.

Temperature

displays “HC”

Beer level probe detects

a short circuit

1. Check beer level probe connection

2. Check controller for short circuit

Turn off EB120, and

cooling water

continues to flow

through the system.

Check the proportional

solenoid control valve

1. Try turning the system on and off again, or

disconnect the system from the power

connection, and reconnect.

2. Check proportional valve. Clean it or change it

Unplug from power

supply, and cooling

water continues to

flow through the

system.

Check:

1. Water inlet valve

2. Circuit board

Change circuit board or water inlet valve

Turn off EB120, but

it continues to

operate.

Check:

f. Circuit board

g. Controller

h. Relays on accessory

circuit board

i. Water level probe

Unplug or disconnect the unit from power.

DO NOT CONTINUE TO USE WITHOUT FIRST

CONTACTING YOUR DEALER!

Chapter Six: Regular Use and Maintenance

The single biggest problem with boilers is the build up of scale resulting from dissolved solids within the beer.

Scaling can cause the heating elements to fail, the beer level sensors not to function, and premature failure of the

O-rings resulting in leaks from around the elements. The extent of the problem will vary according to the degree

of impurities in the beer.

* IMPORTANT NOTICE: DO NOT ATTEMPT TO RUN ANY MASH OR LIQUID WITH SUSPENDED

IMPURITIES DIRECTLY THROUGH THE EB120 WITHOUT FIRST STRAINING AND FILTERING.

DOING SO WILL CLOG THE BEER PUMP, SOLENOID VALVE, AND BOILER, AND WILL VOID

YOUR WARRANTY. WE RECOMMEND PRE-SCREENING WITH A FINE STAINLESS STEEL

SCREEN, THEN FILTERING WITH AT LEAST A 10-MICRON FILTER BEFORE ALLOWING YOUR

BEER TO BE PUMPED INTO THE EB120.

We also recommend descaling the boiler once every 50 to 100 hours of operation. To descale use a solution of

weak acid crystals (such as citric acid) mixed with water. Citric acid crystals are available in packets for descaling