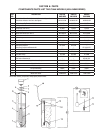

4-1

SECTION 4: SERVICE INSTRUCTIONS

Problem Cause Solution

1) Hard water, (unit NOT using salt;

liquid level in brine tank NOT too

high).

A. Electrical service to unit interrupted. A. Assure permanent electrical service (check fuse, plug,

pull chain or switch.)

B. Timer not working. B. Replace timer motor.

C. Timer improperly set. C. Increase frequency of regeneration and/or salt setting.

D. Safety brine valve not opening. D. Replace safety brine valve.

E. Salt “bridged” in brine tank. E. Breakup salt.

2) Hard water, (unit using salt; liquid

level in brine tank NOT too high).

A. Bypass open. A. Close bypass (replace if necessary).

B. Timer improperly set. B. Increase frequency of regeneration, or reset timer if

needed.

C. No salt in brine tank. C. Add salt; maintain above water level.

D. Excessive water usage. D. Increase frequency of regeneration and/or salt setting

(See HOW TO SET TIMER).

E. Unit installed backwards. E. Reinstall unit.

F. Unit undersized F. Replace with larger unit.

3) Liquid level in brine tank TOO

high.

A. Brine valve not closing. A. Replace brine valve.

B. Salt setting too high. B. Reset timer.

C. Injector screen plugged. C. Clean injector and screen.

D. Drain line frozen, plugged or restricted. D. Free drain.

E. Salt "mushed" or sand from salt plugging

bottom of brine tank.

E. Clean out brine tank (See Instructions).

F. Incorrect brine line fl ow control (BLFC). F. Replace with correct fl ow control (See Specifi cations).

4) System regenerates at wrong

time-of-day.

A. Power outage occurred. A.

Reset timer.

5) Water continuously fl ows to

drain.

A. Foreign material in control valve. Remove piston assembly and inspect bore; remove

foreign material and check control in various regen-

eration positions.

B. Internal control leak. Replace seals and/or piston assembly.

C. Control valve jammed in brine or backwash

position.

Replace piston, seals and spacers.

6) Water tastes salty. A. Salt setting too high. A. Reset program cycle.

B. Cyclone (distributor) tube too short. B. Replace.

7) White spots on glassware and

dark surfaces.

A. Sodium residual resulting from water having

very high hardness or total dissolved solids

(TDS).

A. Installation of additional water treatment equipment

such as reverse osmosis or demineralization.

8) Low water pressure (low fl ow

rate).

A. Iron build-up in line to water conditioner. A. Clean line to water conditioner.

B. Iron build-up in water conditioner. B. Clean control and add Iron-X Mineral Cleaner to resin

bed; increase frequency of regeneration.

C. Well pumping sand. C. Install sand trap.

D. Pump losing capacity. D. Contact pump repair service.

9) “Rotten egg” smell (from hot

water ONLY).

A. Magnesium rod in water heater. A. Replace with aluminum rod or remove.

10) “Rotten egg” smell (from both

hot and cold water).

A. Hydrogen sulfi de ("sulfur") in water supply. A. Install Sulfur Reduction System.

B. Bacterial iron in water supply. B. Install Chem-Free Iron Reduction System.

C. Algae in water supply. C. Pour approximately 1/2 cup laundry bleach into brine

well just before regeneration as frequently as neces-

sary.

11) Loss of resin through drain line. A. Air in water system. A. Assure that well system has proper air eliminator

control; check for dry well condition.

B. Incorrect Drain Line Flow Control (DLFC). B. Replace with correct DLFC.