26

Part Number PLUS-E017-A/1206

PLUS LINE

Indirect-Fired Water Heaters – Series 3

Install system water piping (space heating) (continued)

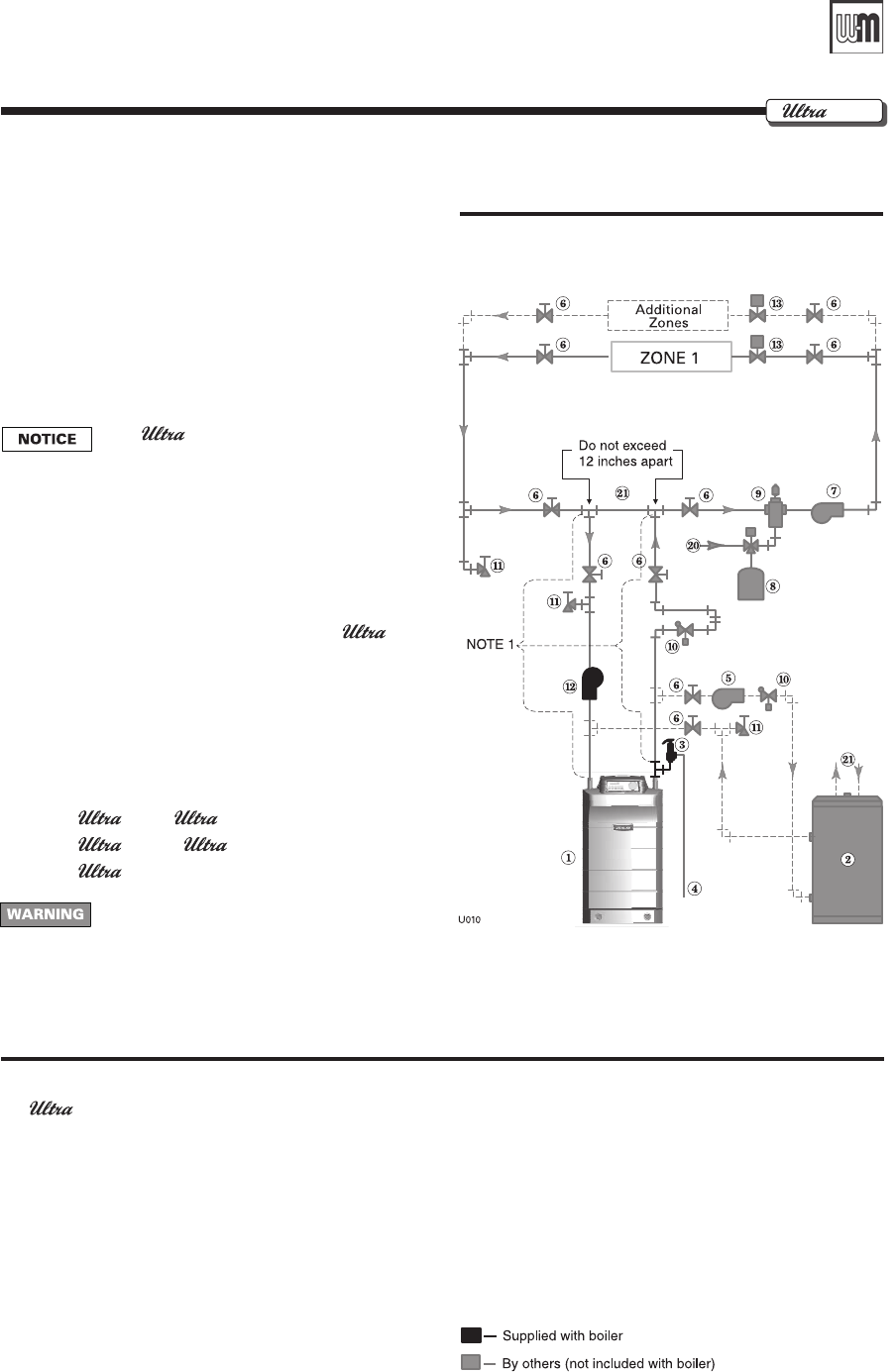

Figure 12 Zone valve zoning plus optional water

heater piping

Zoning with zone valves

1. Connect boiler to system as shown in Figure 12

when zone valve zoning. The primary/secondary

piping shown ensures the boiler loop will have suf-

ficient flow. It also avoids applying the high head

of the boiler circulator to the zone valves.

2. Connect water heater (domestic hot water) pip-

ing to indirect storage water heater as shown in

Section A of this manual.

The PhD Control Module turns off

space heating during water heater heat-

ing. The boiler circulator will turn off,

preventing hot water from circulating to

the system. The flow/check valve shown

on the boiler outlet piping prevents grav-

ity circulation in the boiler loop during

water heater heating.

3. Controlling the system circulator

a. To cycle the system circulator from the PhD

control module, add a circulator relay wired to the

boiler circulator terminals as shown on page 30.

Legend Figure 12

1 boiler

2 PLUS-Line indirect water heater

3 Boiler relief valve (see boiler manual for piping details)

4 Boiler relief valve discharge piping (see boiler manual for

details)

5 Water heater circulator (see page 7 for suggested

sizing)

6 Isolation valves

7 System circulator

8 Diaphragm (or bladder) type expansion tank (see page 3

for piping of closed-type expansion tank, if used)

9 Air separator [with automatic air vent only on systems

using diaphragm (or bladder) type expansion tank]

10 Flow/check valves (with weighted seats to prevent gravity

circulation)

11 Purge/drain valves

12 Boiler circulator

13 Zone valves, typical

20 Make-up water supply

21 Primary/secondary connection

NOTE 1: To ensure adequate flow rate through the

boiler, use the following pipe size on all

boiler loop piping (connecting boiler to and

from the primary/secondary connection,

item 21):

-80 or -105 – 1” or larger.

-155 or -230 – 1¼” or larger.

-310 – 1½” or larger.

Use at least the minimum piping size

above and pipe the boiler using only pri-

mary/secondary piping as shown. Failure

to follow these guidelines could result in

system problems.

B1

Gas