Heating Element

(Sinuated Wire Shown)

1/2 in. (13 mm)

Ceramic Fiber

Insulation

Thermocouple

Mounting

Clamp

2 in.

(50 mm)

Thick Ceramic

Fiber Heater

Mounting

Legs

RAYMAX

®

1220 AND 2030

Raymax

®

1220 and

2030—Ideal For Many

Process Heating

Applications Requiring

"Hot Face" Temperatures

Easy to install and capable of high surface temperatures, the

RAYMAX

®

1220 and 2030 are ideal for many process heating

applications requiring "hot face" temperatures above 540

O

C

(1000

O

F).

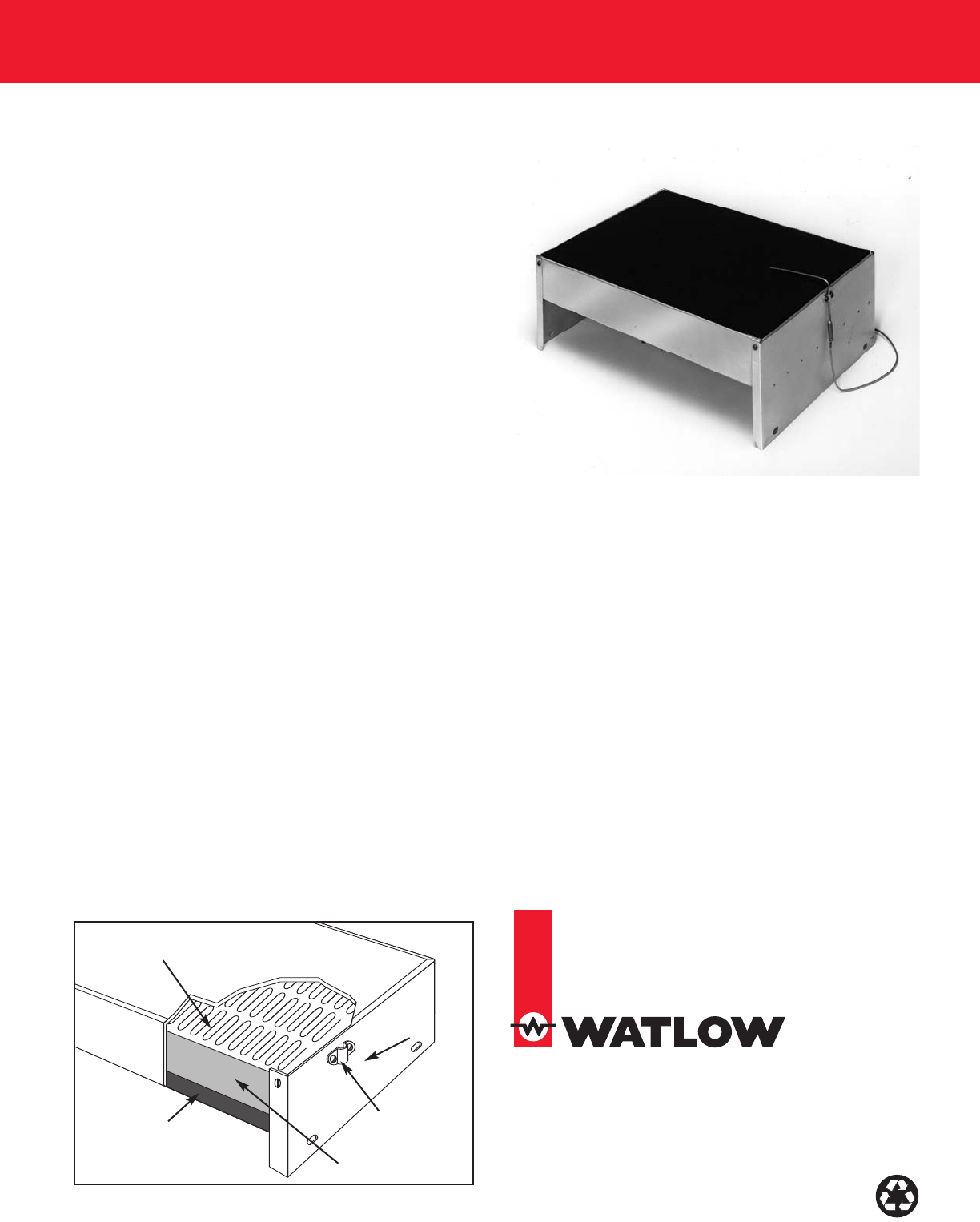

Each unit consists of a ceramic fiber heater mounted in a 2.5 inch

(64 mm) deep sheet metal case that provides thermal insulation.

The case includes post terminals for electrical connections and

provides a mounting system that can be used with virtually any

flat ceramic fiber unit, whether it is a stock, standard or a custom

size. Since any of the flat unit heating element configurations can

be used—exposed sinuated, embedded coil or foil elements—

watt density and temperature capabilities can be tailored to meet

specific radiant applications.

© 2005 Watlow Electric Manufacturing Company Printed in the USA on Recycled Paper, 15% Postconsumer Waste

Features and Benefits

Lightweight, low mass design

• Allows fast response to controls

High efficiency

• Results from high degree of self insulation with 2.5 inch

(64 mm) thick mounting case

Adaptable

• With any stock or standard sized flat ceramic fiber unit

Thermocouple mounting clamp

• Makes process system control easier

Aluminized steel case

• Handles temperatures up to 595

O

C (1100

O

F)

Special hot face heating patterns

• Designed specifically for applications using an etched foil

RAYMAX 1220

12001 Lackland Road

St. Louis, Missouri 63146 USA

Phone: +1 (314) 878-4600

F

AX: +1 (314) 878-6814

Inter

net: www

.watlow

.com

e-mail: info@watlow.com

STL-1220/2030-0805

Applications

•

Con

veyor furnaces

• High temperature vessel heating

• Tempering and annealing processes for glass, wire, ceramics

and metals

• Coating, curing and drying of inks, paints, plastics and films