SUGGESTIONS FOR BURNING ANTHRACITE COAL

1. With coal it is important to maintain a

clean chimney. The chimney connector

and chimney should be inspected at least

twice monthly during heating season.

2. Keep the grate clear of ash and cinders.

Use the shaker grate to keep the ashes

from building up in the firebox.

3. Do not operate the unit with the ash

door, feed door, or cabinet door open.

4. Anthracite coal burns with a short, blue

flame with the coals having a glowing, red

color. Before adding coal, when starting

the fire, have a good hot log fire burning.

5. After having a log fire burning, add

small amounts of coal until a bed of coal is

built up.

6. A draft reading of -.05 to -.06 in w.c. is

required for anthracite to burn.

The draft wheel located on the feed door should be opened when burning coal. The

draft wheel provides a source of secondary air that is needed when burning coal.

Secondary air is needed because when coal burns, it gives off large quantities of

volatile gases that need additional air before complete combustion can occur. This

draft wheel may be adjusted to give the best performance depending on the

particular needs of the user.

TROUBLE SHOOTING TIPS FOR MODEL 2827

LIST OF PROBLEMS POSSIBLE CAUSE SOLUTION

1. Smoking when feed A) Insufficient Draft. A) Set Thermostat high

door is open. B) Clogged chimney or B) Clean Chimney

chimney connector. C) Add raincap to chimney

2. Flame spillage when A) Insufficient Draft. A) Set Thermostat high

feed door is open. B) Smothering fire when B) Add fuel so as not to

adding fresh fuel. smother fire.

3. Creosote build-up A) Burning green wood A) Burn only seasoned

wood.

B) Thermostat setting too B) Set thermostat higher to

low type fuel. attain higher fuel temp-

eratures. This will aid in

preventing build-up of

creosote.

4. Heater does not heat. A) Wood not seasoned A) Allow wood to season

in

a dry, well ventilated

area for 6 months.

B) Blower control set too B) Set blower control to a

low. higher temperature.

C) Insufficient flue draft. C) Set flue draft

(See Page 9)

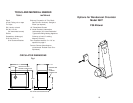

RULES FOR CONNECTOR PIPE INSTALLATION

1. The crimped end of the stovepipe fits

inside the heater flue collar. Install addi-

tional pipe and elbow with the CRIMPED

END TOWARD THE HEATER. This will

allow any condensation in the flue to run

back into the heater.

2. Slope any horizontal pipe upward

toward the chimney at least 1/4 inch for

each foot of horizontal run.

3. You must have at least 18 inches of

clearance between any horizontal pip-

ing and the ceiling.

4. The pipe cannot extend into the

chimney flue. (Fig. 8)

5. Seal each connector pipe joint with

furnace cement. Also seal the pipe at

the chimney.

6. Use 3 Sheet Metal screws at each

joint to make the piping rigid.

7. It is recommended that no more than

two 90 degree bends be used in the

stovepipe installation as more than two

may decrease the amount of draw and

possible, use only corrugated (non-ad-

justable) elbows. They are much more

airtight.

8. The chimney connector must not

pass through an attic or roof space,

closet, or any concealed space, or floor,

ceiling, wall or combustive construction.

12

C

L

O

S

E

D

O

P

E

N

Fig. 11

RIGHT WRONG WRONG

Fig. 8

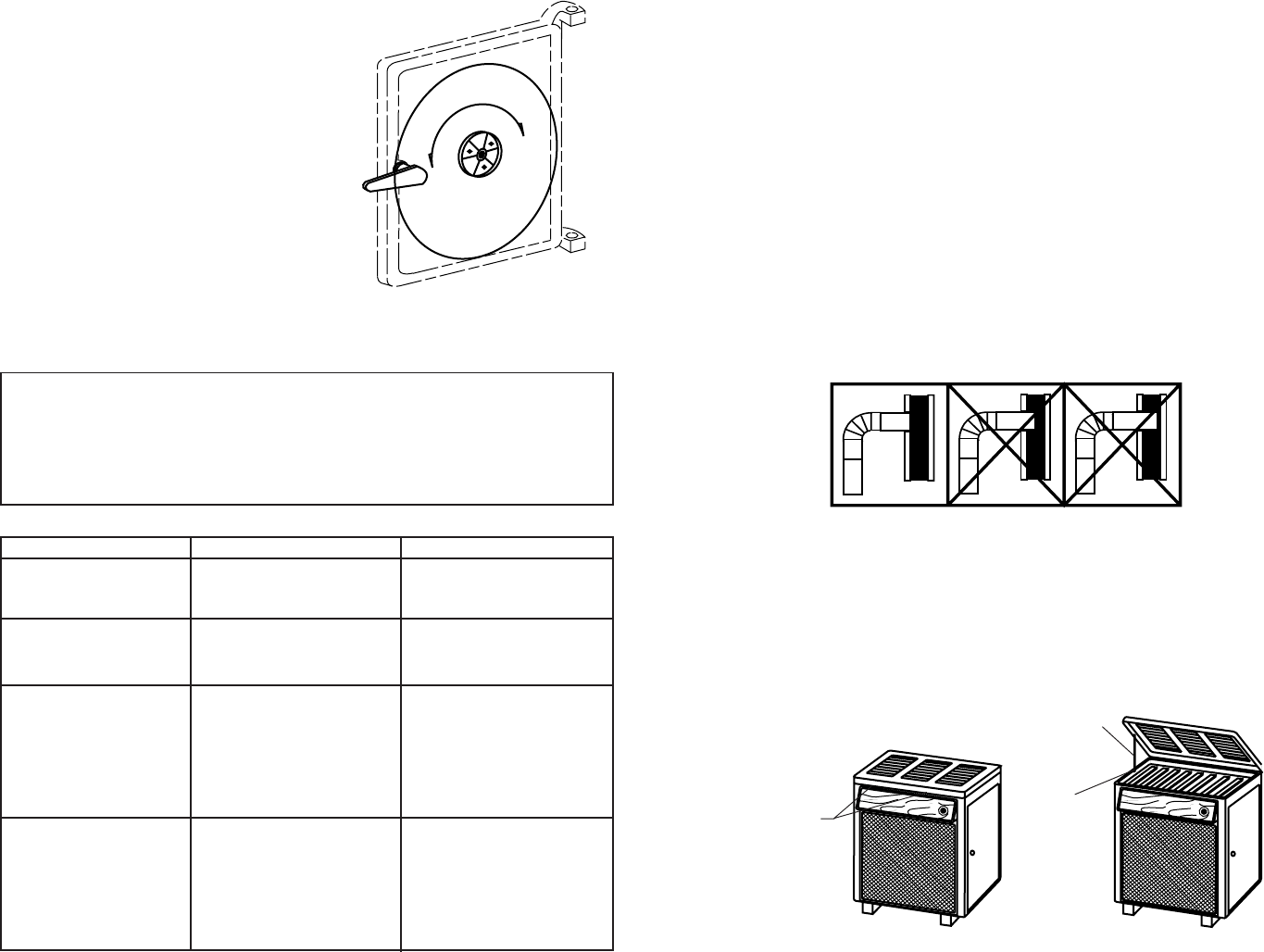

HOW TO LIFT THE TOP

CAUTION - DO NOT OPEN OR CLOSE TOP WHEN HEATER IS HOT!

To open, grasp TOP at front and lift all the way, then gently lower the TOP

SUPPORT ROD latches to hold the TOP (Fig. A).

To close, lift TOP until the TOP SUPPORT ROD is unlatched. Pull the ROD

forward and lower the TOP (Fig. B).

WONDERCOAL

WONDERCOAL

GRASP TOP

HERE

TO OPEN

SUPPORT ROD

TOP

SUPPORT

SEAT

Fig. 9

A

B

9