CHIMNEY CONNECTION

Two basic types of chimneys are approved for use with solid fuel: Factory-built and

masonry. Factory-built chimney must comply with UL103HT standard.

Do not expect your stove or furnace to create draft. Draft is not a function of the

appliance. Draft is purely a function of the chimney. Modern stoves and furnaces

are much more airtight and efficient than those of the past; and, therefore require

greater draft. A minimum of .05, measured in water column (gauges to measure

chimney draft are readily available at stove shops and are economical to purchase

or rent) is required for proper drafting to prevent back-puffing, smoke spillage, and

to maximize performance.

Chimneys perform two functions - one of which is apparent: The chimney provides

a means for exhausting smoke and flue gases resulting from combustion of the fuel.

Secondarily, though, the chimney provides "Draft" which allows oxygen to be

continuously introduced into the appliance, so that proper combustion is possible.

As of April 1, 1987, all heaters and furnaces manufactured by United States Stove

Company should be installed using a factory built chimney that meets the "Type HT"

requirement of UL 103 (when a factory - built chimney is used).

IMPORTANT

*Size the chimney to the flue outlet on the stove. (6" outlet = 6" I.D. chimney)

*Avoid using elbows except as necessary (they reduce draft).

*Make sure all horizontal runs of connector pipe go up hill (1/4" elevation for each

horizontal foot).

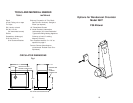

Fig. 5

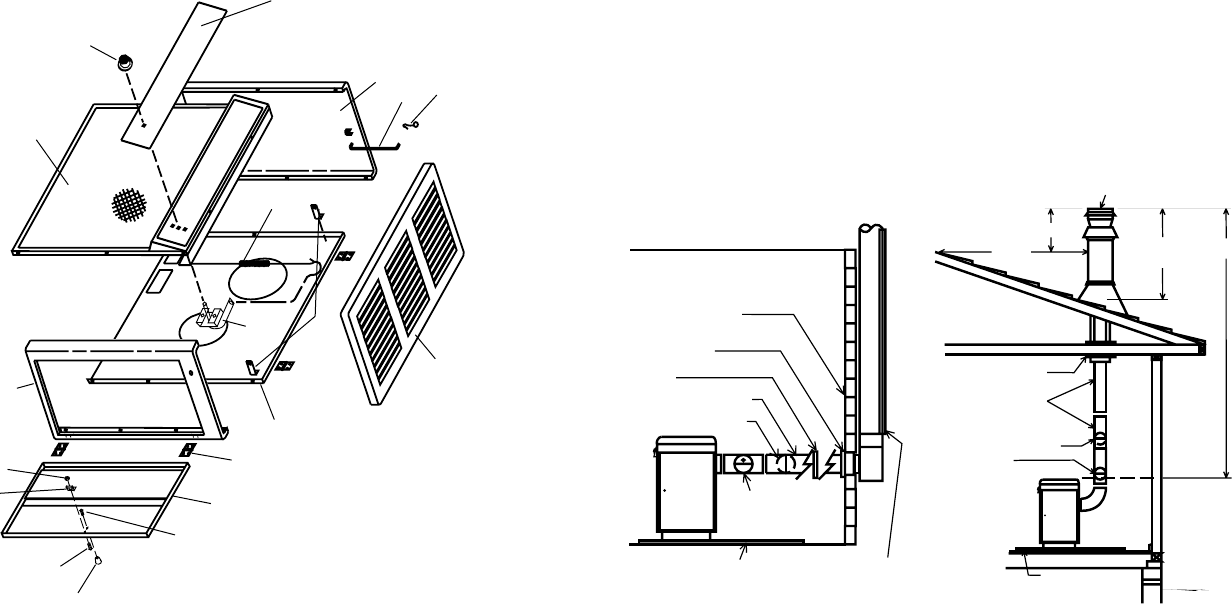

Fig. 6

516

PIPE

FLOOR PROTECTOR

REFER TO CHIMNEY

MANUFACTURERS PARTS

AND INSTRUCTIONS

2 FT MIN.

10 FT.

3 FT.

MIN.

CAST IRON DAMPER

BAROMETRIC

DRAFT CONTROL

(OPTIONAL)

11 FT. MIN.

CHIMNEY CAP MANDATORY

THIMBLE

COLLAR

CAST IRON DAMPER

PIPE

NON-COMBUSTIBLE

WALL

FLOOR PROTECTOR

CLASS A UL 103HT

CHIMNEY KIT INCLUDING

WALL THIMBLE.

BAROMETRIC

DRAFT CONTROL

(OPTIONAL)

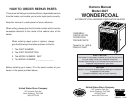

18

15

1

2

17

6

3

5

16

10

19

13

12

9

7

4

8

11

REPAIR PARTS

AUTOMATIC COAL BURNING CIRCULATOR HEATER

MODEL 2827 - EXTERIOR

14

W

O

N

D

E

R

C

O

A

L