RT-PRC001-EN8

Reference or Comparative Enthalpy

Measures and communicates humidity

while maximizing comfort control.

Sloped Drain Pans

Standard on every unit.

Standardized Components

Components are placed in the same

location on all Voyager units. Familiarize

yourself with one Voyager and you are

familiar with every Voyager.

Due to standardized components

throughout the Voyager line, contractors/

owners can stock fewer parts.

Supply and/or Return Air Smoke

Detector

With this option installed, if smoke is

detected, all unit

operation will be shut

down. Reset will be

manual at the unit.

Return Air Smoke

Detectors require

minimum allowable

airflow when used

with certain models.

Tool-less Hail Guards

Tool-less, hail

protection quality coil

guards shall be either

factory or field-installed for condenser

coil protection. This option protects the

condenser coil from vandalism and/or

hail damage.

Trane Communication Interface (TCI)

Available factory or field installed. This

module when applied with the ReliaTel™

easily interfaces with Trane’s Integrated

Comfort

TM

System.

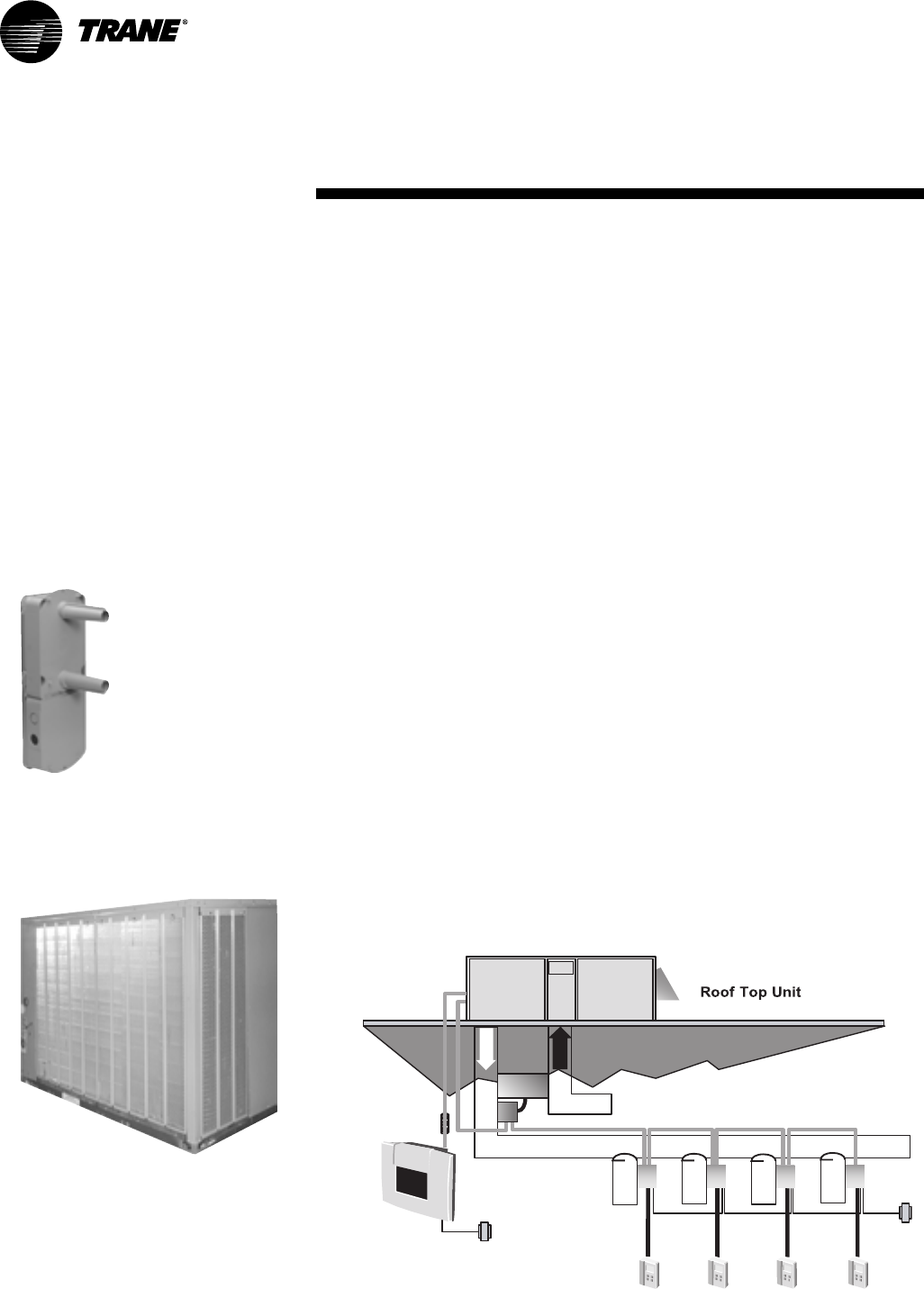

VariTrac

When Trane’s changeover VAV System

for light commercial applications is

coupled with Voyager, it provides the

latest in technological advances for

comfort management systems and can

allow thermostat control in every zone

served by VariTrac.

Ventilation Override Accessory

With the Ventilation Override Accessory

installed, the unit can be set to transition

to up to 3 different pre-programmed

sequences for Smoke Purge,

Pressurization, and Exhaust. The

transition occurs when a binary input on

the RTOM is closed (shorted). This would

typically be a hard wired relay output

from a smoke detector or fire control

panel. The ventilation override kit is

available as a field installed accessory.

Zone Sensors

Available in programmable, automatic

and manual styles.

Rigorous Testing

The fan and idler arm assembly designs

have been tested to over 300,000 cycles

each. Our combined cycle testing is now

over 7,000,000 cycles.

All of Voyager’s designs were rigorously

rain tested at the factory to ensure water

integrity.

Actual shipping tests were performed to

determine packaging requirements. Units

were test shipped around the country to

determine the best packaging. Factory

shake and drop tests were used as part

of the package design process to help

assure that the unit arrives at the job site

in top condition.

Rigging tests include lifting a unit into the

air and letting it drop one foot, assuring

that the lifting lugs and rails hold up under

stress.

We perform a 100% coil leak test at the

factory. The evaporator and condenser

coils are leak tested at 200 psig and

pressure tested to 450 psig.

All parts are inspected at the point of final

assembly. Sub-standard parts are

identified and rejected immediately.

Every unit receives a 100% unit run test

before leaving the production line to

make sure it lives up to rigorous Trane

requirements.

Voyager units incorporate either a one

piece top or the Trane-Tite-Top (T

3

). Each

part of the top (either two or three pieces)

overlaps in such a way that water cannot

leak into the unit. These overlapped edges

are gasketed and sealed to ensure

superior water integrity.

VariTrac™

Features and

Benefits