26

5/32” GAP

ELECTRODE

NOZZLE

0-1/16”

5/16” ABOVE CL

air, to a larger number (clockwise) for more air.

Tighten the lock nut after completing the adjust-

ment. For best results, use instruments to

measure between 8-9% CO

2

after the combus-

tion air has been adjusted.

Oil Gun Only

It is recommended that the CO

2

and Smoke

levels should be measured for maximum per-

formance. CO

2

readings should be 10-11% for

66,000 BTUH furnaces and 12-13% for 86,000

BTUH furnaces. The Smoke should be N0. 0 on

the Bacharach Scale, and 0 to 0.02 negative

draft over fire.

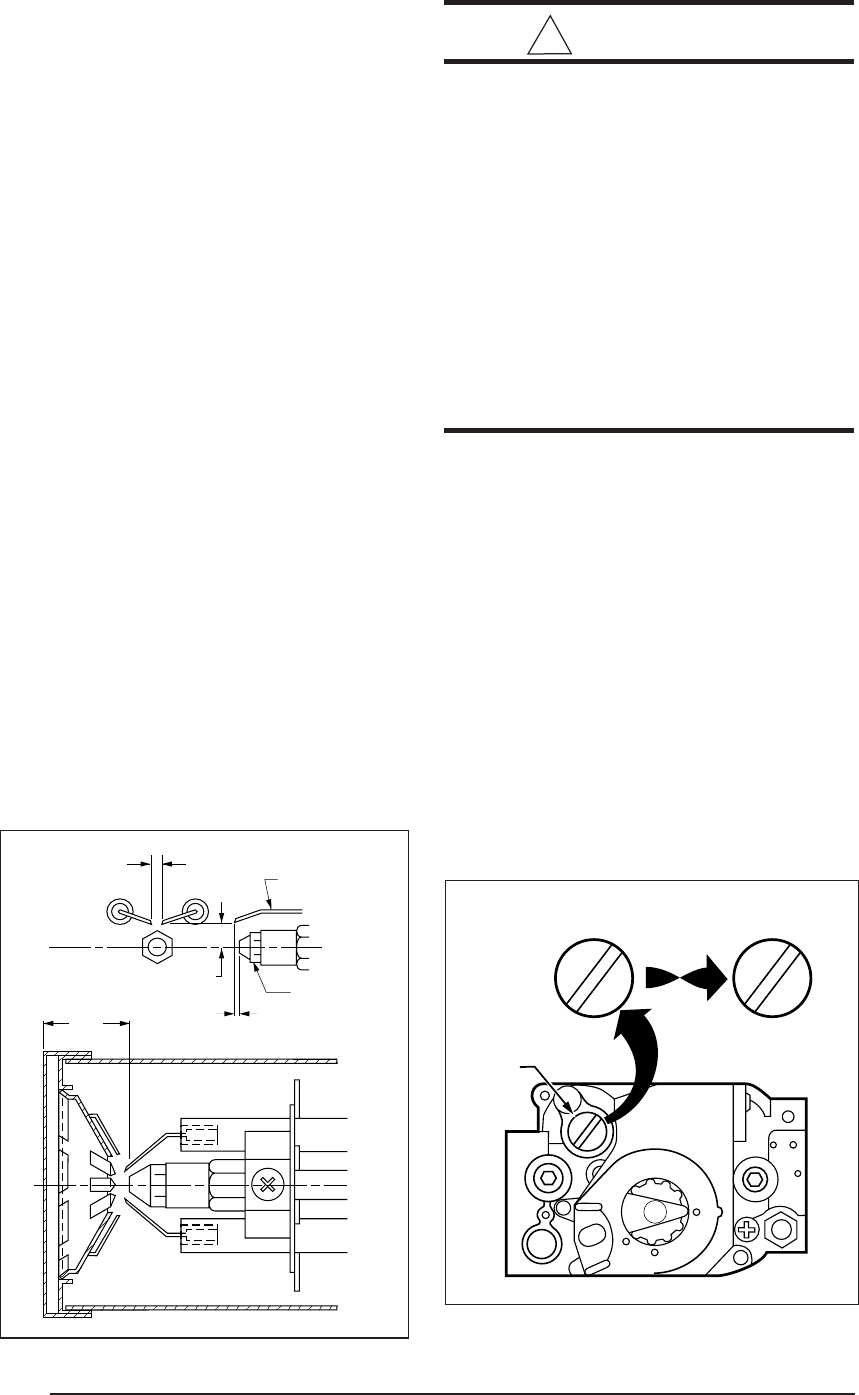

Electrode Setting (Oil Gun Only)

Poor ignition of the oil spray may result if the

electrodes are not adjusted as shown in Figure

32. Do not permit any electrodes to be grounded

to any surface.

Switching the Honeywell R7184 Ignition

Control between Interrupted and Intermit-

tent Duty (Oil Gun Only)

The Honeywell oil primary control can be

switched between interrupted and intermittent

ignition control. To switch from interrupted duty

(Factory set) to intermittent duty, remove the

igniter wire from the blue control wire. Attach the

burner motor and igniter wire to the orange

control wire. Cap and reseal the orange control

wire. Cap and isolate the blue control wire.

!

CAUTION:

• Combustion air adjustment must be

made only by a qualified technician.

Improper air adjustment may cause

unsafe operation, explosion and/or

fire asphyxiation.

• If the input to the furnace is too great

because of excessive gas pressure,

wrong size nozzle or orifice, high alti-

tude, etc., the burner flame will be

sooty and can produce carbon mon-

oxide, which could result in unsafe

operation, explosion and/or fire or

asphyxiation.

GAS CONVERSION

This gas fired heating appliance was shipped

from the factory for use with natural gas. How-

ever, the appliance can be converted for use

with LP gas. Use the following procedure for

gas conversion of the burner.

ATMOSPHERIC AND DIRECT IGNITION

FURNACES

a. Follow the instructions to “Turn Off Gas to the

Appliance.”

b. Disconnect the gas pipe union and the elec-

trical wires connected to the gas valve.

c. Remove the pilot tube and thermocouple

from the gas valve (M1G*).

1 3/8”

Figure 32. Oil Gun electrode Position

Figure 33. Convertible Pressure

Regulator Cap

PRESSURE

REGULATOR

CAP

M11678

N

A

T

N

A

T

L

P

L

P

N

A

T

N

A

T

OR

OTHER SIDE

OF CAP

Honeywell

Valve