PURGING PROCEDURES

Connect the refrigerant pipes (both liquid pipe and the gas pipe) between the indoor

and the outdoor unit.

Remove the service port cap of the stop valve on the side of the outdoor unit gas

pipe. (The stop valve will not work in it initial state fresh out of the factory (totally

closed with cap on).)

Connect the gauge manifold valve and the vacuum pump to the service port of the

stop valve on the gas pipe side of the outdoor unit.

Run the vacuum pump. (Vacuumize for more than 15 minutes.)

Check the vacuum with the gauge manifold valve, then close the gauge manifold

valve, and stop the vacuum pump.

Leave as it is for one or two minutes. Make sure the pointer gauge manifold valve

remains in the same position. Confirm that the pressure gauge shows–0.101 Mpa

[Gauge] (–760 mmHg).

Pipe length exceeding 7 m

Charge the prescribed amount

of gas. (refer to 3)

Remove the gauge manifold valve quickly from the service port of the stop valve.

After refrigerant pipes are connected and evacuated, fully open all stop valves on

both sides of gas pipe and liquid pipe.

Operating without fully opening lowers the performance and this causes trouble.

Tighten the cap to the service port to obtain the initial status.

Retighten the cap.

Leak test

*Close

*Open

Hexagonal wrench

Stop valve

*4 to 5 turns

Stop valve

(or the vacuum

pump with the

function to

prevent the

back flow)

Gauge manifold

valve (for R410A)

Pressure gauge

(for R410A)

Compound pressure

gauge (for R410A)

-0.101MPa

(-760 mmHg)

Handle

Low

Handle High

Window

Charge hose

(for R410A)

Vacuum

pump

Adapter for

preventing

the back flow

Charge hose

(for R410A)

Service port

Stop

valve

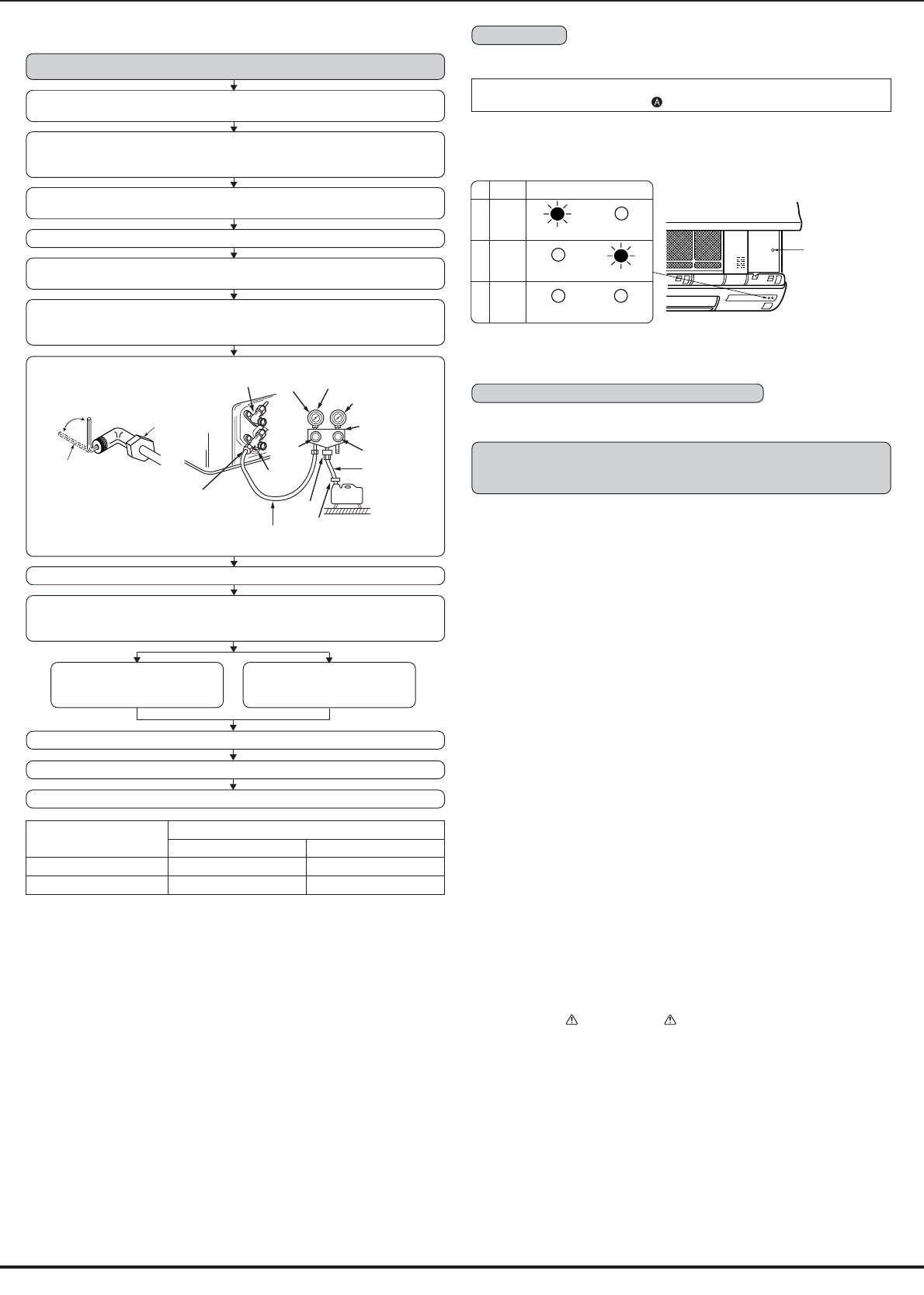

EMERGENCY

OPERATION switch

Mode Operation Indicator lamp

1

COOL

(Light) (Off)

2

HEAT

(Off) (Light)

3

STOP

(Off) (Off)

6-4 PURGING PROCEDURES·LEAK TEST

PROCEDURE

•

Press the EMERGENCY OPERATION switch.

1 Press it once, and after test run for 30 minutes the EMERGENCY COOL MODE starts.

If the left side lamp of the operation indicator blinks every 0.5 seconds, inspect the

indoor/outdoor unit connecting wire

for mis-wiring.

2 Press it once more, and the EMERGENCY HEAT MODE starts.

3 Press it once more, and the operation stops.

(The operation mode changes in order of 1 ~ 3 every time the EMERGENCY

OPERATION switch is pressed.)

•

In starting the heating operation, indoor unit fan may not operate to prevent blowing

cool air. Please wait for a few minutes until the temperature of heat exchanger rises and

warm air blows out.

Checking the remote (infrared) signal reception

Press the ON/OFF button on the remote controller and check that an electronic sound is

heard from the indoor unit. Press the ON/OFF button again to turn the air conditioner off.

If the indoor unit is operated with the remote controller, both the test

run and the emergency operation are released by commands from

the remote controller.

•

Once the compressor stops, the restart preventive device operates so the compressor

will not operate for three minutes to protect the air conditioner.

6-6 EXPLANATION TO THE CUSTOMER

•

Using the OPERATING INSTRUCTIONS, explain the following to the customer, how to

control temperature, how to remove the air filters, how to remove or put the remote

controller in the remote controller holder, how to clean, precautions for operation, etc.

•

Recommend the customer to read the OPERATING INSTRUCTIONS carefully.

6-7 CHECKING AFTER INSTALLATION

After finishing the installation, check the following items and mark the next to each item.

Is the specified power supply voltage used?

Is the power line equipped with the circuit breaker?

Have the ends of the indoor/outdoor connecting wire been properly inserted into the

terminal blocks?

Has the indoor/outdoor connecting wire been secured firmly?

Are the power supply cord and indoor/outdoor connecting wire connected directly to

the units (no intermediate connections)?

Is the earth wire longer than the other wires so that it will not become disconnected

when tension is applied?

Is the earth wire connected properly?

Are the pipes designed for use with R410A or do they have the specified thickness?

Has the leak test been carried out for the pipe connections?

Has air purging been carried out?

Are the stop valves open fully?

Is the drain hose properly installed?

Has water been poured through the drain hose to confirm proper drainage?

Are the pipes at the rear of the unit bundled with felt tape (for left and left-rear piping

only)?

Can the installation location bear the weight of the unit and not amplify its vibration or

noise?

Is the area under the unit free of objects that block the air outlet?

Are the vertical and horizontal vanes closed securely?

Is the front panel installed securely?

Has the test run been carried out?

Has the drain work been performed properly and are there no bubbling sounds?

Have all of the

WARNING and CAUTION items in “1. THE FOLLOWING

SHOULD ALWAYS BE OBSERVED FOR SAFETY” been checked?

6-8 EXPLANATION TO THE CUSTOMER

•

Using the OPERATING INSTRUCTIONS, explain the following to the customer, how to

control temperature, how to remove the air filters, how to remove or put the remote

controller in the remote controller holder, how to clean, precautions for operation, etc.

•

Recommend the customer to read the OPERATING INSTRUCTIONS carefully.

6-5 TEST RUN

•

Before performing the test run, recheck any wrong wiring.

Wrong wiring prevents normal operation or results in blown fuse disabling operation.

•

The test run can be started by pressing EMERGENCY OPERATION switch. When the

EMERGENCY OPERATION switch is once pressed, the unit will start the test run

(continuous operation) for 30 minutes.

A thermostat does not work during this time. After 30 minutes the unit will start the

EMERGENCY OPERATION at a fixed temperature setting of 24°C in COOL MODE or

HEAT MODE.

•

Perform test run in the following procedure.

140 to 180

200 to 300

Tightening torque

N·m kgf·cm

Cap for service port

Cap for stop valve

13.7 to 17.7

19.6 to 29.4

Pipe length up to 7 m

No gas charge is needed.