17

Leak test:

1. Mix a 50-50 solution of water and dish soap.

2. Light appliance- see lighting instructions on page

22 of this manual or on the stove’s rating plate.

3. Brush or spray all joints and connections with the

soapy water solution.

4. If bubbles appear at any connection or seam or a

gas odor is detected immediately turn gas control

knob to the OFF position.

5. Tighten or reconnect the leaking joint and retest

for any gas leaks.

Gas Pressure

It is important that the correct pressure is estab-

lished at the time of the installation. Proper gas

pressure provides a consistent flow of gas to the

appliance and is instrumental in checking for gas

leaks. The gas control valve on the stove is equipped

with pressure test points for gauge connections. The

gauge connections are located on the front of the

valve under the On/Off/Pilot- knob. See Fig. 18.

Gauge connections are identified by:

•E for inlet or supply pressure ( the amount of gas

coming to the valve.)

•A for manifold pressure (the amount of gas that

is coming out of the valve to the burner.)

ALWAYS TEST PRESSURES WITH VALVE CONTROL

KNOB SET ON HIGH.

Gas Connection

NOTE: IF THE OPTIONAL BLOWER KIT (# 129161) IS

TO BE INSTALLED ON THE STOVE AT THE TIME OF THE

INSTALLATION OR IN THE FUTURE, THE GAS SUPPLY

LINE SHOULD BE INSTALLED AS CLOSE TO THE FLOOR

AS POSSIBLE. USE OF A 90° ELBOW DIRECTLY OFF THE

VALVE TO ALLOW FOR ADEQUATE CLEARANCE FOR

THE BLOWER. See Figure 15.

The gas supply line connection is made to the

valve just inside the left rear leg. The Gas supply line

should be 3/8" or 1/2" diameter, or the appropriate

size to provide sufficient gas pressure to the valve

regardless of the input setting.

The use of Flexible Gas Appliance Connectors is

acceptable in many areas in the U.S., however,

Canadian methods vary depending on local code.

ALL INSTALLATIONS MUST COMPLY WITH LOCAL

CODE OR IN THE ABSENCE OF LOCAL CODE, MUST

COMPLY WITH THE MOST RECENT EDITION OF THE

NATIONAL FUEL GAS CODE ANSI Z223.1/NFPA 54 OR

CAN-B149.

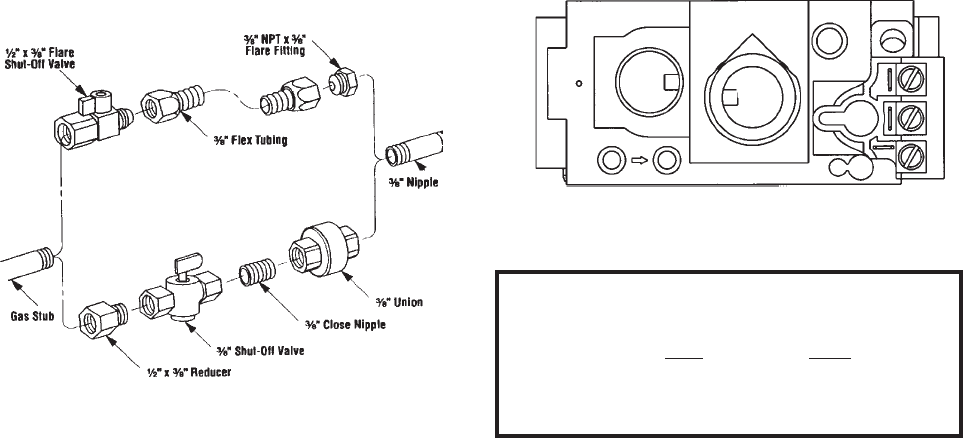

All codes require a gas shutoff valve (gas cock)

and union to be installed in the supply line and in

the same room as the appliance for servicing and

maintenance. See Figure 17.

T-handle gas cocks are required in Massachu-

setts in compliance with Code 248 CMR.

Secure all joints tightly using appropriate tools

and sealing compounds (for propane units be sure to

use compounds that are propane resistant). Turn on

gas supply and test for gas leaks using a soapy water

solution. Never use an open flame to check for

leaks.

Figure 17. Gas supply valve types and fittings.

INLET GAS PRESSURES

(inches water column)

MIN MAX

NATURAL GAS 5.0 WC 7.0 WC

PROPANE 11.0 WC 13.5 WC

Figure 18. Inlet and Manifold pressure test points.

EA

Control Valve