3

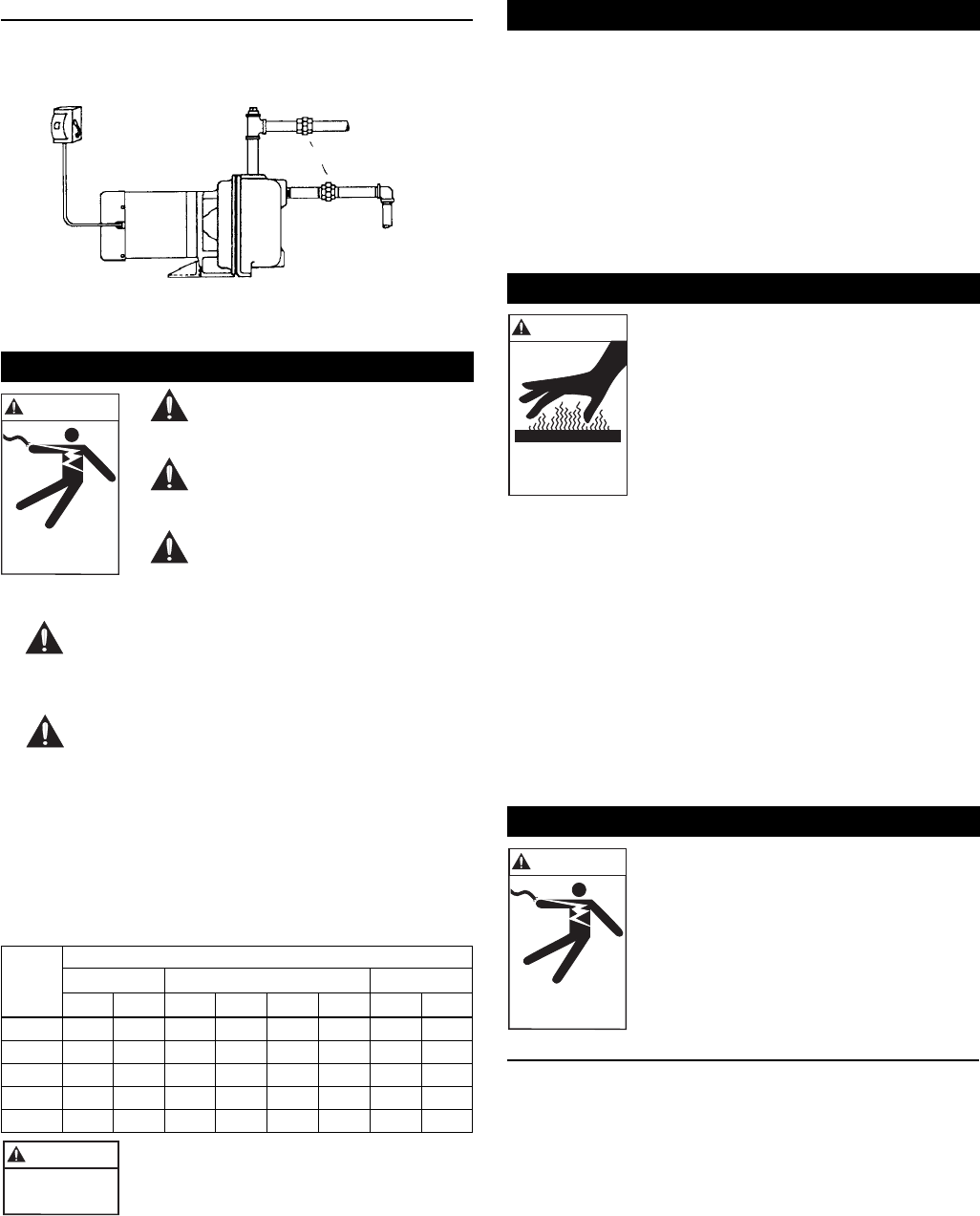

DISCHARGE

• Install a tee at the discharge connection of the pump.

The top opening of the tee is required for initial priming.

See Figure 1.

Figure 1

Wiring and Grounding

Install, ground and wire

according to local and National

Electrical Code requirements.

Install an all leg electrical power

disconnect switch near the

pump.

Disconnect electrical power

before installing or servicing

pump.

Electrical supply MUST match pump’s

nameplate specification. Incorrect voltage can

cause fire or damage to the motor and voids

warranty.

Motors without built-in protection MUST be

provided with contactors and thermal overloads

for single phase motors, or starters with heaters

for three phase motors. See motor nameplate.

• Follow motor manufacturer’s wiring diagram on the

motor nameplate or terminal cover carefully.

• Use only copper wire to motor and ground. The ground

wire MUST be at least as large as the wire to the motor.

Wires should be color coded for ease of maintenance.

RECOMMENDED MINIMUM WIRE SIZE

Distance from Service Entrance to Motor

HP 50 Ft. (15 m) 100 Ft. (30 m) 150 Ft. (46 m) 200 Ft. (61 m)

115 V 230 V 115 V 230 V 115 V 230 V 115 V 230 V

3

⁄4 12 14 10 14 8 14 6 12

1 12 14 8 14 8 12 6 12

1

1

⁄2 10 14 8 14 – 12 – 10

2 10 14 8 14 – 12 – 10

3 – 12 – 12 – 10 – 10

FAILURE TO PERMANENTLY

GROUND THE PUMP, MOTOR AND

CONTROLS BEFORE CONNECTING

TO ELECTRICAL POWER CAN

CAUSE SHOCK, BURNS, OR DEATH.

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Extreme heat can

cause personal injury

or property damage

PRIMING OPENING

FUSED OR

CIRCUIT BREAKER

DISCONNECT MEANS

SUCTION

UNION

WARNING

Hazardous voltage

can shock, burn or

cause death.

WARNING

Hazardous

voltage

Rotation

NOTICE: INCORRECT ROTATION MAY CAUSE

DAMAGE TO THE PUMP AND VOIDS THE

WARRANTY.

• Correct rotation is right hand, CLOCKWISE when

viewed from the motor end.

• Three phase unit rotation may be checked by removing

motor end cap or plug and observing rotation of motor

shaft. To reverse rotation, reverse any two of the three

motor leads.

Operation

OPERATION WITHOUT PRIME, OR

AGAINST A CLOSED DISCHARGE

VALVE, CAN GENERATE HOT

WATER OR STEAM CAUSING

INJURY OR PROPERTY DAMAGE.

NOTICE: DO NOT OPERATE PUMP

WITHOUT PRIME OR SEAL

DAMAGE WILL RESULT.

• Prime pump by filling pump and piping through opening

in top of tee with clean water. See Figure 1.

• Install pipe plug in top of tee using Teflon

TM

tape or

equivalent.

NOTICE: IF PUMP IS DRAINED OR SHUT OFF

DURING PRIMING PERIOD, CASING

MUST BE REFILLED BEFORE

RESTARTING PUMP.

• Start the pump and partially open discharge valve and

wait for system pressure to stabilize. If system pressure is

surging, or prolonged pressure drop is experienced, the

system may not be completely primed.

Maintenance

FAILURE TO DISCONNECT

ELECTRICAL POWER BEFORE

ATTEMPTING ANY MAINTENANCE

CAN CAUSE SHOCK, BURNS OR

DEATH.

• No lubrication is required on pump.

For motor lubrication, refer to and

follow manufacturer’s instructions.

SEASONAL SERVICE

• To REMOVE pump from service, remove all drain plugs

and drain all piping.

• To RETURN pump to service, replace all drain plugs

using Teflon

TM

tape or equivalent.

• Reconnect suction line if removed, examine union and

repair if necessary.

• Reprime and operate pump following all instructions

and warnings in the “OPERATION” section of manual.