STRYKER VAV USER GUIDE

62-2030—01 18

Setpoint Configure the setpoints to be used by the loop in different occupancy modes. Configure the

minimum and maximum reset values to be used and the corresponding reset sensor values.

Reset value to be added to the setpoint is calculated by the controller as a value between min max

reset values in proportion to the reset sensor value.

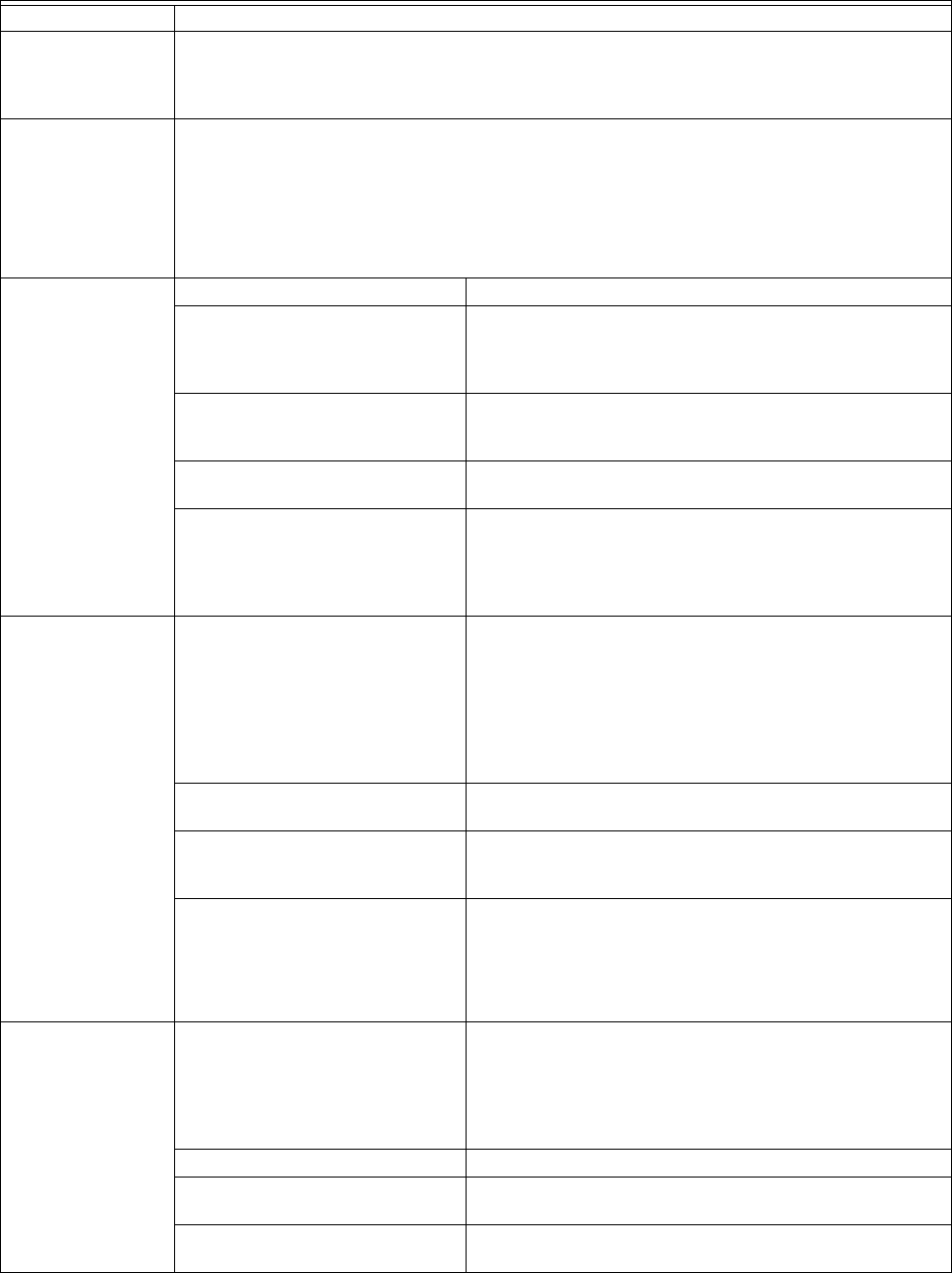

Control Parameters Parameters that affect the output and the loop behavior can be configured. Below are the

configurable parameters and its descriptions.

NOTE: If derivative time is set to zero, it disables derivative action.

NOTE: Modulating output threshold value for activating the Auxiliary output can be con-

figured to control the auxiliary output based on the value of PID loops modulating

output.

Control Parameters Configurable Parameters Description

Throttling range This is the proportional change in the sensed variable

required to change the control output from 0 to 100 percent.

This needs to be configured in the engineering unit of the

main input sensor

Integral time This determines the integral gain of the PID loop. The

greater the time in seconds, the less the integral change per

second. A setting of 0 eliminates the integral function.

Derivative time Determines the derivative gain in a PID loop. The greater the

time in seconds, the greater the derivative effect per second

PID action Direct Acting or Reverse Acting selection determines the

behavior of the loop output. In a direct acting control loop the

output increases as the input sensor value rises above the

setpoint. In a reverse acting control loop the output

increases as the input falls below the setpoint.

Control Parameters Aux DO action This determines the Aux DO behavior. The Aux output can

be configured for either continuous or intermittent operation.

This selection applies to occupied and standby modes only.

Unoccupied is always intermittent. In continuous operation

the output is continuous, regardless of the operation of the

other outputs of the loop. In intermittent operation the output

is on only when the modulating output of the loop is greater

than 0 or at least one of the staged outputs is on.

Modulating control for Aux This option allows the Aux DO to be controlled based on the

value of the loops modulating output.

Modulating output threshold for Aux Modulating output threshold value for controlling the

Auxiliary output. The Aux DO is activated if the PID

modulating output is greater than the threshold value

Aux output minimum off time The auxiliary digital output minimum off time.

NOTE: When staged outputs are configured this value

must be configured to be less than (Cycler and

stager interstage minimum on time - Aux output

run on time).

Control Parameters Aux output run on time The auxiliary digital output run-on time. A value of 0 disables

the run-on time. This is typically used when the AuxDo is

configured for intermittent operation.

For example, If the AuxDO is controlling the fan, this

parameter can be used to keep the fan running for certain

duration after the cooling or heating process has stopped.

Minimum off time This is the minimum off time for the staged outputs

Cycler and stager interstage

minimum on time

This is minimum amount of time a lower numbered stage

must be on before the next stage can turn on.

Minimum on time This is the minimum on time for the Aux DO and staged

outputs

Table 11. Accessory Loop Fields. (Continued)

Name Definition