5

VENT PIPE AND DRAFT HOOD SIZES

Refer to Chart 3 to properly size the flue pipe. If the flue pipe exceeds 10’ in length

(including elbows), use the next larger diameter flue pipe and draft hood. If a draft regulator is

required, any Canadian Standards Association (CSA) or Underwriter’s Laboratory (UL) listed

double swing draft regulator must be used.

A movable internal damper is not permitted on gas

installations.

When the burner is used as a conversion burner, draft over fire should be maintained

as –0.02” W.C. by adjusting the regulator when the burner is fired. The installer should follow the

barometric draft regulator manufacturer’s instructions for complete details for installations and

adjustments. The vent pipe should extend only to (but not beyond) the inside wall of the chimney.

The sizing below does not apply on any factory listed packaged units.

Chart 3: Vent Pipe Sizing

Input per Hour

Draft Hood and Flue Pipe Sizes

Up to 120,000 BTU

5” diameter

120,000 to 160,000 BTU

6” diameter

160,000 to 250,000 BTU

7” diameter

INSTALLING THE BURNER

If the burner being installed is a conversion burner, use a prefabricated chamber or build a

firing chamber that can withstand 2000

o

F (See Chart 2 on page 3). Measure the boiler or furnace

mounting plate to determine the flame tube insertion required. Deduct ¼” from the total length

and tighten the flange on the flame tube with the deducted insertion depth. The ¼” deduction will

prevent the tip of the flame tube from burning off. Install the burner on the unit and then tighten

the nuts on the flange so that the burner is permanently secured. Seal off any free openings with

high temperature cement.

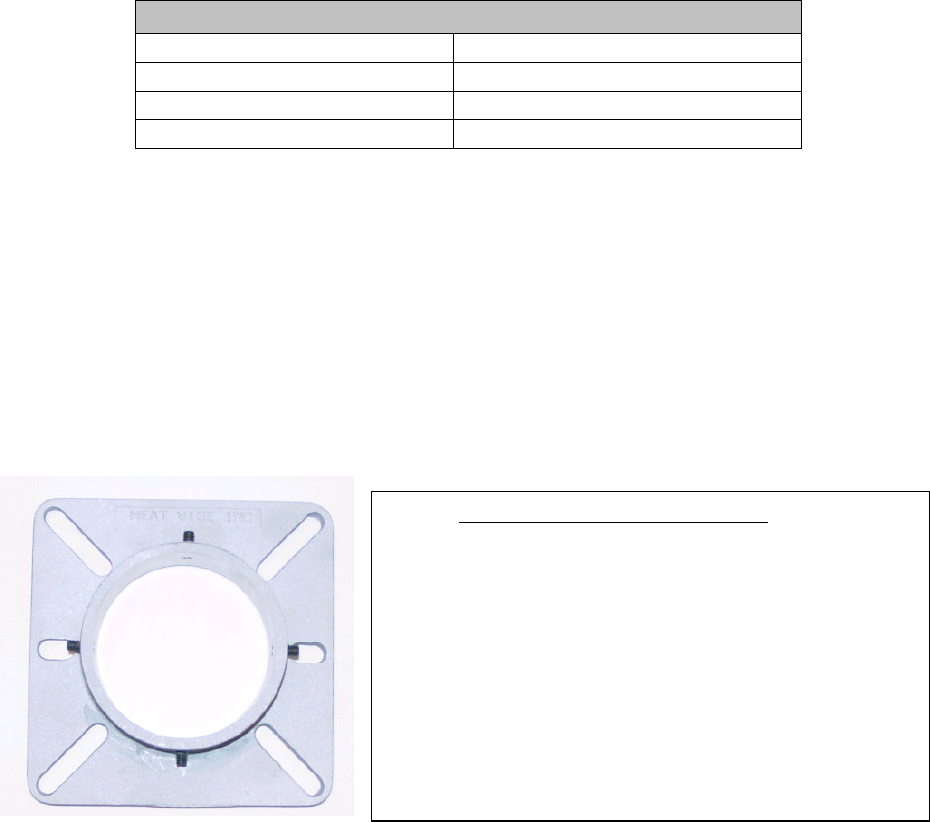

Refer to the pictures below to determine which flange is installed on the SU-2A

Picture 1: STANDARD FLANGE:

Install the gasket and the Standard flange to the

boiler. Tighten the bolts. Measure the boiler or furnace-

mounting plate to determine the flame tube insertion depth

required and make a mark on the tube (with a marker or

screwdriver). Deduct ¼” from the total length and tighten

the flange on the flame tube with the deducted insertion

depth. The ¼” deduction will prevent the tip of the flame

tube from burning off. Slide the blast tube into the boiler to

the proper depth and tighten the four ¼”-

20 setscrews. Seal

off any free openings with either high temperature cement

or high temperature silicone.