MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 14 of 28 flowserve.com

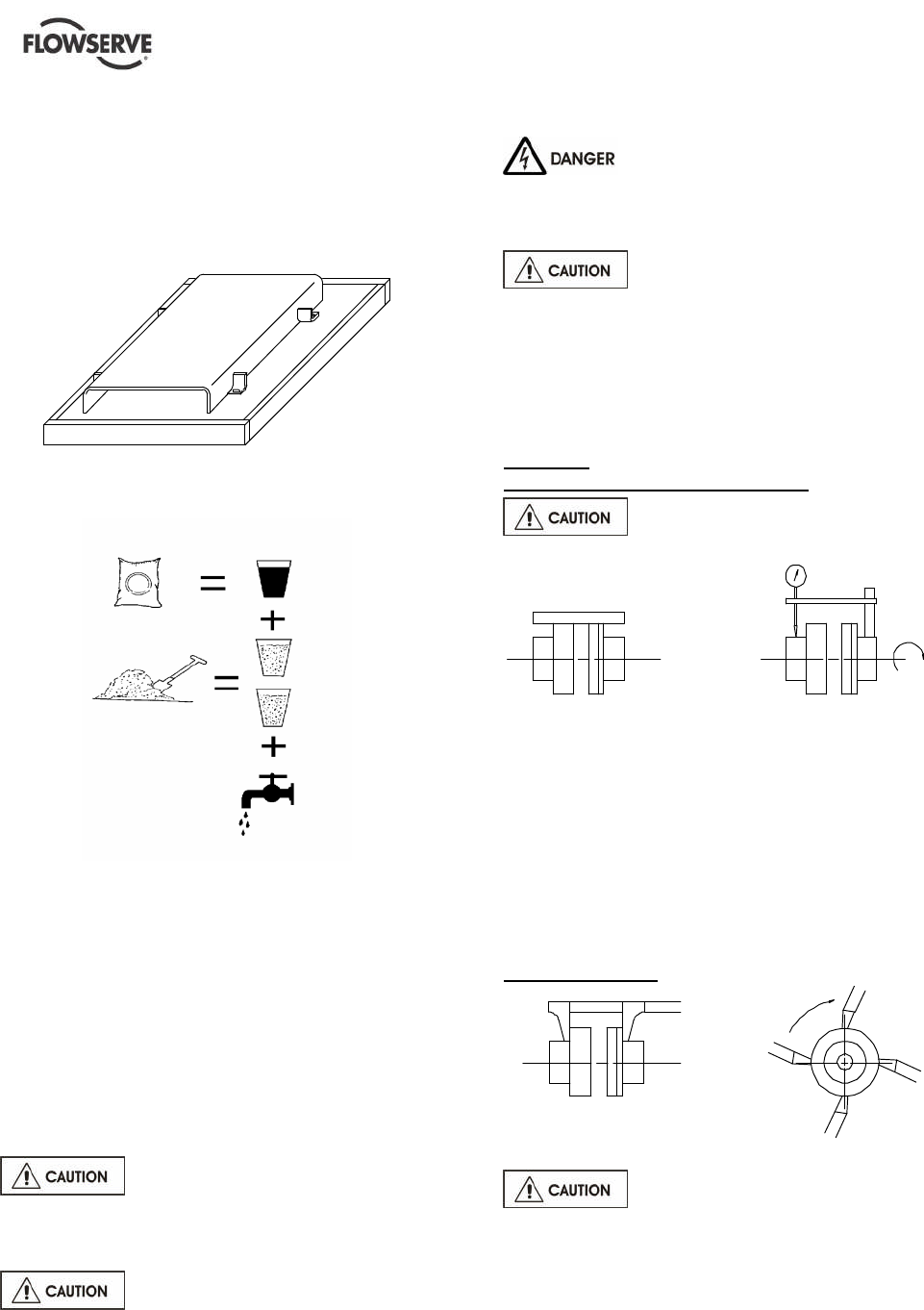

4.3 Grouting

4.3.1 Base plate grouting

a) Prepare the site for grouting. Before grouting

clean the foundation surface thoroughly and

provide external barriers as shown:

b) Prepare grouting product (concrete, resin) in

accordance with manufacturers' instructions.

c) Use grouting products with anti-shrinking

components.

d) To grout up to the required level. Polish

surfaces. Take necessary precautions to avoid

air bubbles.

e) Lay-down the barrier, break external angles,

and polish the different surfaces.

f) After grout starts to cure, definitively tighten

anchor bolts.

g) Control the alignment such as described as

follows.

4.4 Initial alignment

Before connecting the couplings

verify the motor rotation direction.

4.4.1 Thermal expansion

The pump and motor will normally

have to be aligned at ambient temperature and

should be corrected to allow for thermal expansion

at operating temperature. In pump installations

involving high liquid temperatures, the unit should

be run at the actual operating temperature, shut

down and the alignment checked immediately.

4.4.2 Alignment methods

Ensure pump and driver are isolated

electrically and the half couplings are

disconnected. Ensure that the pump pipework,

suction and discharge, is disconnected.

The alignment MUST be checked.

Although the pump will have been aligned at the

factory it is most likely that this alignment will have

been disturbed during transportation or handling. If

necessary, align the motor to the pump, not the

pump to the motor.

Alignment

Parallelism and concentricity check:

Check the alignment at three or

four points, before piping assembly.

with a rule with a comparator

Admissible margin for a motor with roller bearings

with European couplings:

= 0.15 mm parallel checking

= 0.1 mm angular checking

For US supplied couplings values to be used are:

= 0.02 in. parallel checking

= 0.05 in. angular checking

Check the couplings manual for further details.

Angular checking:

with a sliding rule with a caliper gauge

The alignment will be definitive only

after pipe connection (see § 4.5.4).

If necessary, improve the machine alignment:

Complete unit mounted on common base plate:

The machines are first aligned accurately in our

workshops. Usually, any misalignment observed

on site is due to a wrong adjustment under the

base plate (disturbed during transport or because

of forces exerted by the piping).