4

Installation and Operations Manual

the area above the unit cooler must be sealed or exposed in such a way

to facilitate hand cleaning without the use of tools. When lagging or

bolting the unit ush to the ceiling, seal the joint between the top and

the ceiling with an NSF listed sealant and ends of open hanger channels

must be sealed to prevent accumulation of foreign matter.

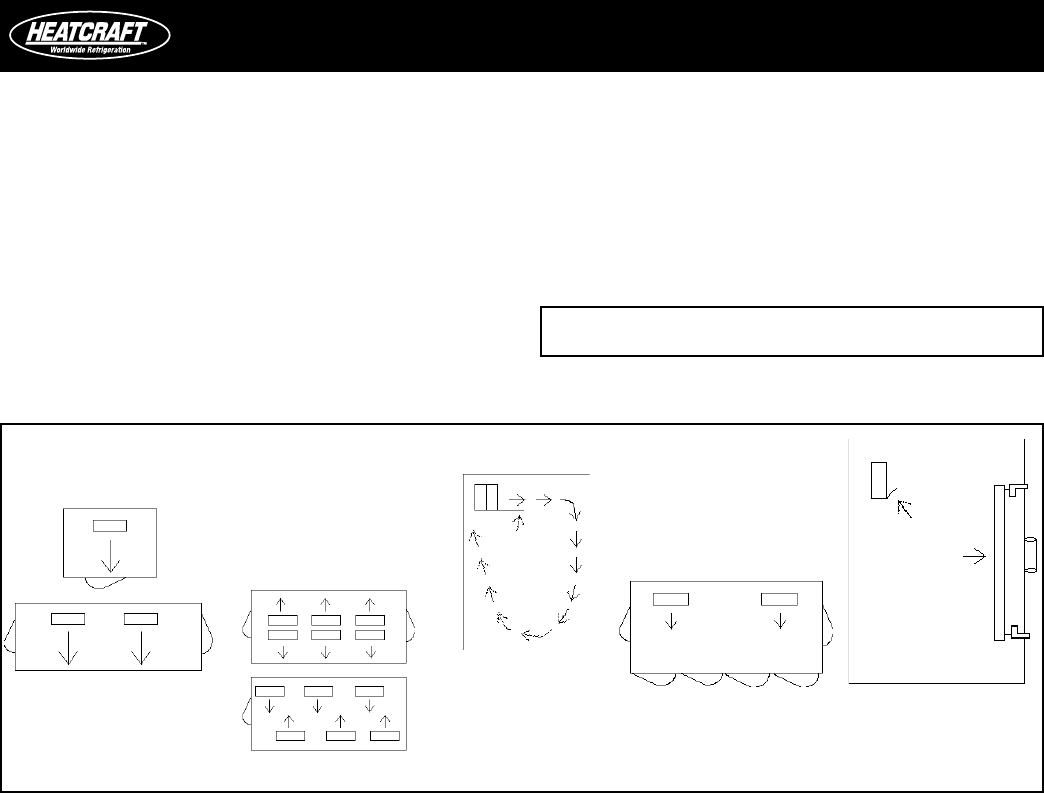

When locating unit coolers in a cooler or freezer, refer to Figures 1

through 4 for guidelines.

Unit Cooler Mounting

Most evaporators can be mounted with rod hangers, lag screws, or

bolts. Use 5/16" bolt and washers or rod for up to 250 pounds, 3/8"

for up to 600 pounds and 5/8" for over 600 pounds. Care should be

taken to mount the units level so that condensate drains properly.

Note that some unit cooler designs achieve drain pan slope by using

dierent height mounting brackets. In this situation, the top of the

mounting brackets should be level. Adequate support must be

provided to hold the weight of the unit.

When using rod hangers, allow adequate space between the top of

the unit and the ceiling for cleaning. To comply with NSF Standard 7,

Figure 4. Large Coolers and Freezers Placement.

Elevation view of glass display

door cooler or freezer. Be sure

air discharge blows above, not

directly at doors. Provide bae if

door extends above blower level.

Glass

Display

Door

Bae

Where one wall evaporator

mounting is satisfactory.

Cooler or Freezers

where one wall will not

accommodate all required

evaporators or where air

throw distance must be

considered.

Baed Unit - Allow sucient

space between rear of Unit Cooler

and wall to permit free return of

air. Refer to Figures 1 through 3

(page 3) for proper space.

Cooler or Freezer with Glass

Display Doors

NOTE: Always avoid placement of Unit Coolers direct above

doors and door openings.

Defrost Troubleshooting

Fan Motor

If the motor does not operate or it cycles on thermal overload, remove

motor leads from terminal block and apply correct voltage across the

leads. If motor still does not operate satisfactorily, it must be replaced.

Before starting the unit, rotate fan blades to make sure they turn freely

and have sucient clearance.

Fan Delay & Defrost Termination Control

This control is a single pole double throw switch. The red lead wire

is wired to common. The black wire is wired in series with the fan

motors. The brown wire is wired in series with the defrost termination

solenoid in the timer. The brown and red contacts close and the black

and red contacts open when the temperature is above 55

º

F. The black

and red contacts close and the brown and red contacts open when

the temperature is below 35

º

F.

On initial “pull down” of a warm box the fan will not start until

the coil temperature reaches approximately 35

º

F. If the box is still

comparatively warm (60

º

F) when the fan starts, then blowing this

warm air over the coil may cause it to warm up to 55

º

F and thus stop

the fan. Therefore, the fan may recycle on initial “pull down.” This

control cannot be adjusted.

If the fan motor fails to start when the control is below 35

º

F, disconnect

the fan motor leads and check the motor as described for fan motors.

Also check whether current is being supplied at “N” and “4” from the

timer. The fan delay control must be below 35

º

F when checking for

a closed circuit.

Defrost Heater

If unit shows very little or no defrosting and does not heat, disconnect

heater and check to nd if it is burned out. To test, apply correct voltage

across heater or use continuity ashlight battery tester.

Drain Pan

If drain pan has an ice build-up, drain line may be frozen. The

drain line should be pitched sharply and exit cabinet as quickly as

possible. Sometimes location and ambient at the drain outside of

cabinet may cause freeze-up. A drain line heater may be required

to correct the freeze-up. Any traps in the drain line must be located

in a warm ambient.