Torque Instruct

ions

Torque Instructions

If fluid cover o

r manifold fasteners have been

loosened, it i

s important to torque them using the

following pro

cedure to improve sealing.

NOTE: Fluid cover and manifold fasteners have a

thread-locking adhesive patch applied to the threads.

If this patch is excessively worn, the fasteners may

loosen during operation. Replace screws with new

ones or apply medium-strength (blue) Loctite or

equivalent to the threads.

NOTE: Always completely torque fluid covers before

torquing manifolds.

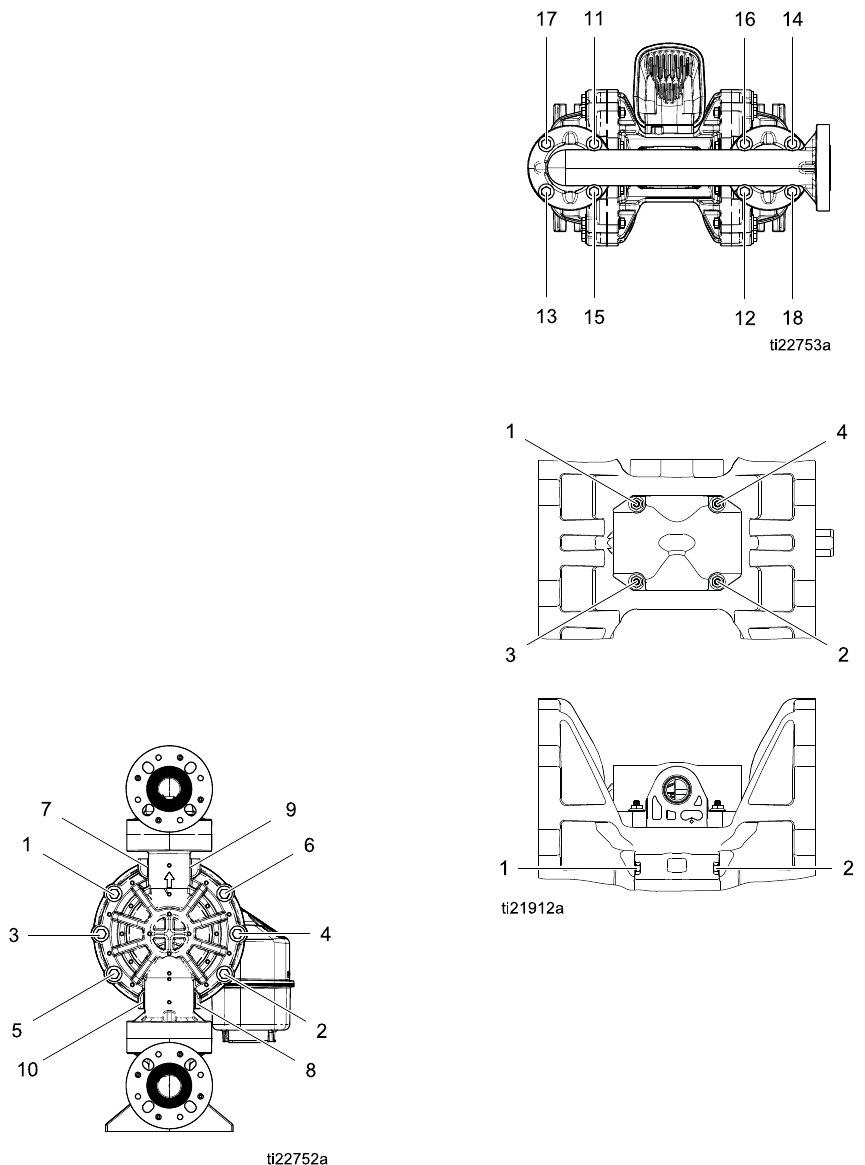

1. Start all fl

uid cover screws a few turns. Then, turn

down each s

crew just until head contacts cover.

2. Turn each s

crew by 1/2 turn or less working in a

crisscro

ss pattern to specified torque.

3. Repeat fo

r manifolds.

Fluid cover and manifold fasteners: 190to220

in-lb (21 to 25 Nm)

4. Retorque the air valve fasteners in a crisscross

pattern to the specified torque.

Air valve fasteners: 45to55in-lb(5to6Nm)

5. Retorque the pilot valves to the specified torque.

Do not overtorque.

Pilot v

alves: 20to25in-lb(2to3Nm)

Fluid Cover Screws

Inlet and Outl

et Manifold Screws

Air Valve Screws and Pilot Valves

3A2889A 19