Operation

14 311826C

5. Cycle the pump slowly until all air is pushed out and

the pump and hoses are fully primed. Release the

gun trigger and lock the trigger safety latch. The

pump should stall against pressure when the trigger

is released.

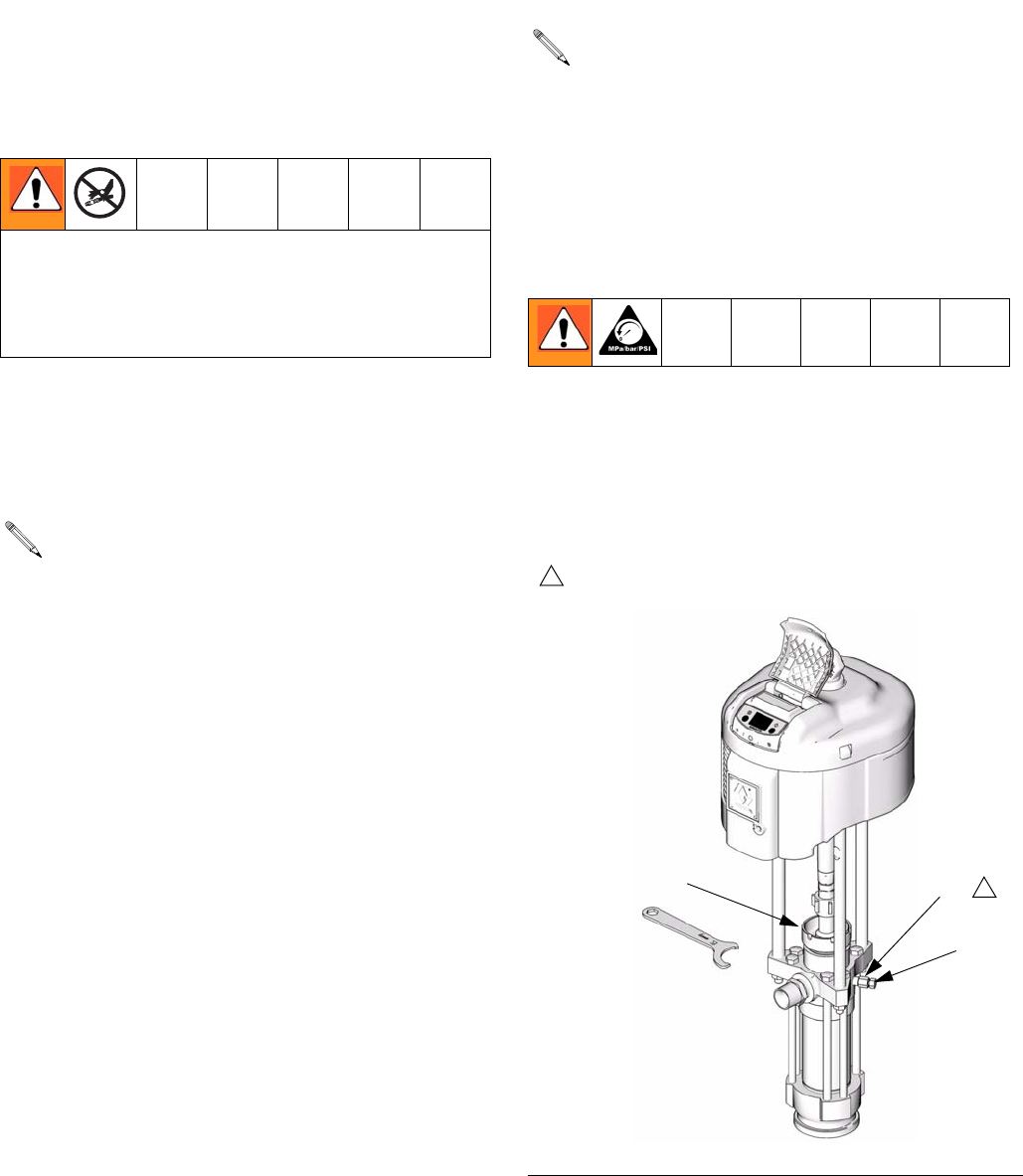

6. If the pump fails to prime properly, open the bleeder

valve plug (AB) slightly. Use the bleed hole as a

priming valve until the fluid appears at the hole. See

F

IG. 3. Close the plug (AB).

7. With the pump and lines primed, and with adequate

air or hydraulic pressure and volume supplied, the

pump will start and stop as the gun is opened and

closed. In a circulating system, the pump will speed

up or slow down on demand, until the air or hydrau-

lic supply is shut off.

8. Always use the lowest air or hydraulic pressure nec-

essary to get the desired results. Higher pressures

cause premature tip/nozzle and pump wear.

a. For air-powered pumps, use the air regulator (F)

to control the pump speed and fluid pressure.

b. For hydraulic-powered pumps, use the fluid

pressure gauge (F) and flow control valve (G) to

control the pump speed and the fluid pressure.

9. Never allow the pump to run dry of the fluid being

pumped. A dry pump will quickly accelerate to a

high speed, possibly damaging itself.

Shutdown

Relieve the pressure, page 13. Stop the pump at the

bottom of its stroke to prevent fluid from drying on the

exposed displacement rod and damaging the throat

packings.

Do not use your hand or fingers to cover the bleed hole

on the underside of the bleeder valve body (AA) when

priming the pump. Use a wrench to open and close the

bleeder plug (AB). Keep your hands away from the

bleed hole.

When changing fluid containers with the hose and

gun already primed, open the bleeder valve plug

(AB), to assist in priming the pump and venting air

before it enters the hose. Close the bleeder valve

when all air has been eliminated.

If your pump accelerates quickly, or is running too

fast, stop it immediately and check the fluid supply.

If the supply container is empty and air has been

pumped into the lines, refill the container and prime

the pump and the lines with fluid, or flush and leave

it filled with a compatible solvent. Be sure to elimi-

nate all air from the fluid system.

FIG. 3. Bleeder Valve and Wet-Cup

TI8364a

AB

AA

AC

Bleed hole must face down.

1

1