7

Remove connecting rod (conrod) screws, and push the front of the conrod parts forward as far as possible into the crosshead

guide.

Important! Conrods are marked for identification. Do not twist conrod halves. When reassembling, conrods are to be fitted

back onto the shaft journals in their exact original position.

Turning the crankshaft gently, tap it out carefully to one side using a rubber hammer.

Important! Do not bend conrod shafts. Check the running surface of the shaft and conrods as well as the shaft seal rings

and tapered roller bearings.

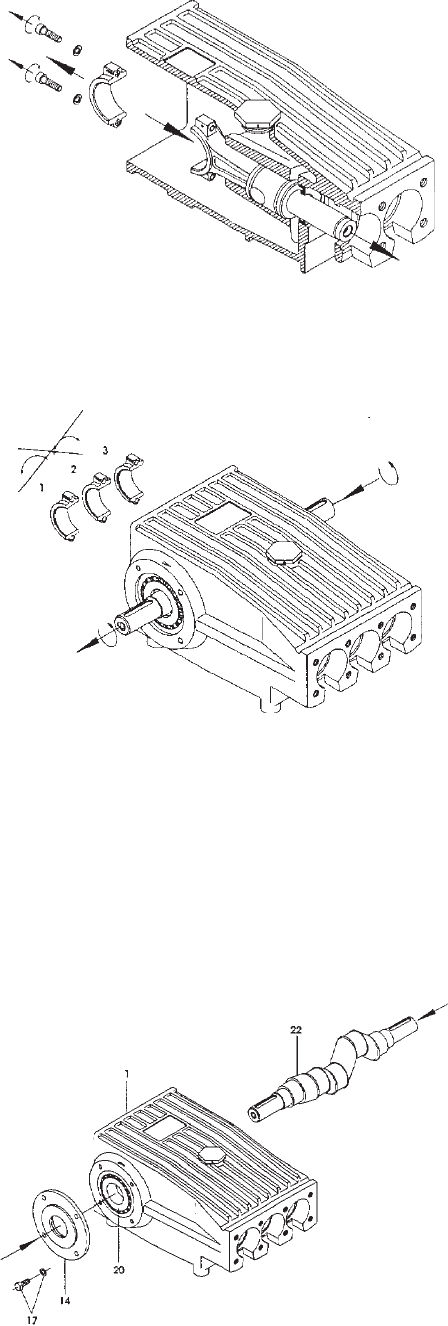

To Reassemble Gear End

Using a soft tool, press in outer bearing ring on one side of the crankcase until its outer edge sits evenly on the bearing bore.

Then screw on bearing cover together with shaft seal ring and O- ring. Insert shaft through the bearing hole on the opposite

side. Press in outer bearing ring and tension inwards with bearing cover, keeping the shaft in vertical position and turning it

slowly so that the tapered rollers of the bearing sit evenly on the outer bearing ring. Adjust axial bearing clearance to at least

0.1mm and maximum 0.15mm by placing fitting discs (20A) under one of the bearing covers.

Important! After assembly has been completed, the shaft should turn easily with very little clearance. Tighten conrod

screws to 26 Ft.-lbs. (35 Nm).