The Vert-I-Pak A series units must be installed with a free

return air configuration. The table below lists the indoor

airflow at corresponding static pressures. All units are rarted

at low speed.

The Vert-I-Pak units are designed for either single speed or

two fan speed operation. For single speed operation refer to

the airflow table below and select the most appropriate CFM

based on the ESP level. Connect the fan output from the

thermostat to the unit on either the GL terminal for low speed

or to the GH terminal for high speed operation.

For thermostats with two-speed fan outputs connect the low

speed output to the unit GL terminal and the high speed

output to the GH terminal.

Ductwork Preparation

Indoor Airflow Data

Fresh Air Door

If flex duct is used, be sure all the slack is pulled out of the

flex duct. Flex duct ESP can increase considerably when

not fully extended. DO NOT EXCEED a total of .30 ESP, as

this is the MAXIMUM design limit for the VERT-I-PAK

A-Series unit.

The Fresh Air Door is an “intake” system. The fresh air door

opened via a slide on the front of the chassis located just

above the indoor coil. Move the slide left to open and right

to close the fresh air door. The system is capable of up to 60

CFM of fresh air @ ~.3” H20 internal static pressure.

IMPORTANT: FLEX DUCT CAN COLLAPSE AND

CAUSE AIRFLOW RESTRICTIONS. DO NOT

USE FLEX DUCT FOR: 90 DEGREE BENDS, OR

UNSUPPORTED RUNS OF 5 FT. OR MORE.

EXAMPLE: Measured voltage to unit (heaters) is 230 volts.

Measured Current Draw of strip heaters is 11.0 amps.

230 x 11.0 = 2530

2530/1000 = 2.53 Kilowatts

2.53 x 3413 = 8635

Supply Air 95

°

F

Return Air 75

°

F

Temperature Rise 20

°

20 x 1.08 = 21.6

8635

= 400 CFM

21.6

1 ½ TON SYSTEM ( 18,000 Btu)

Operating on high speed @ 230 volts with dry coil

measured external static pressure .10

Air Flow = 450 CFM

In the same SYSTEM used in the previous example but

having a WET coil you must use a correction factor of

.95 (i.e. 450 x .95=428 CFM) to allow for the resistance

(internal) of the condensate on the coil.

It is important to use the proper procedure to check

external

Static Pressure and determine actual airfl ow. Since in

the case of the VERT-I-PAK, the condensate will cause

a reduction in measured External Static Pressure for the

given airfl ow.

It is also important to remember that when dealing with

VERT-l-PAK units that the measured External Static

Pressure increases as the resistance is added externally

to the cabinet. Example: duct work, fi lters, grilles.

Checking Approximate Airfl ow

If an inclined manometer or Magnehelic gauge is not

available to check the External Static Pressure, or the

blower performance data is unavailable for your unit,

approximate air fl ow call be calculated by measuring the

temperature rise, then using tile following criteria.

KILOWATTS x 3413

= CFM

Temp Rise x 1.08

Electric Heat Strips

The approximate CFM actually being delivered can be

calculated by using the following formula:

DO NOT simply use the Kilowatt Rating of the heater (i.e.

2.5, 3.4, 5.0) as this will result in a less-than-correct airfl ow

calculation. Kilowatts may be calculated by multiplying

the measured voltage to the unit (heater) times the

measured current draw of all heaters (ONLY) in operation

to obtain watts. Kilowatts are than obtained by dividing

by 1000.

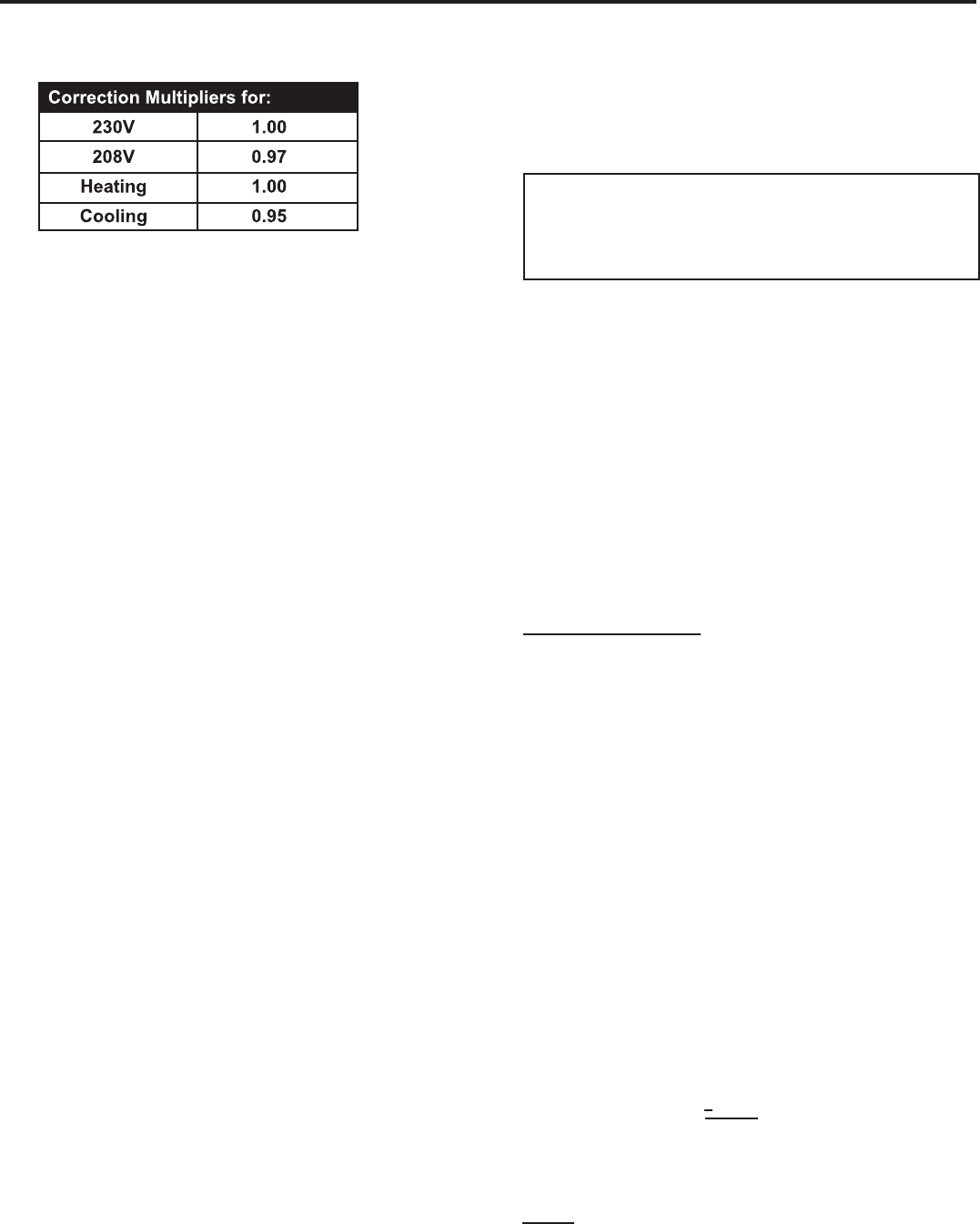

Explanation of charts

Chart A is the nominal dry coil VERT-I-PAK CFMs. Chart

B is the correction factors beyond nominal conditions.

Correct CFM (if needed):

Chart B – Correction Multipli

ers

16