1

GENERAL PLUMBING

FOR SOLVENT WELD CONNECTIONS

Rigid or fl exible PVC pipe can be used. Pipe ends

should be clean and free of any fl ash caused by the

cutting operation. Be sure that the proper adhesive is

used on the type of pipe specifi ed.

Recommended Adhesives- These are examples only

and are not intended to restrict brands.

NOTE: A Primer will assure that adhesives joints are

superior. Sureguard P-3000 has a purple tracer to qualify

in areas where codes specify a primer must be used.

CAUTION- We recommend that you consider

climatic conditions when applying adhesives. Certain

atmospheric situations, such as high moisture content,

make the adhesive action of certain glues less effective.

Check the manufacturer’s instructions.

FOR THREADED CONNECTIONS

Use only Tefl on tape or equivalent on threaded

plumbing connections. Other pipe compounds

may damage threads. We do not recommend the

use of silicone or petroleum based compounds.

DO NOT OVER TIGHTEN! HAND TIGHTEN PLUS 1/2

TURN IS SUFFICIENT.

PUMP PLUMBING

All S & J Series pumps are union connected allowing

quick and easy service without disturbing the plumbing.

Two different plumbing confi gurations are available

offering 1-1/2” suction connection and either 1-1/2”

discharge or 1” tee discharge. These union packages

must be ordered separately. Avoid using a suction pipe

smaller than pump connection.

To maximize the 100% drain feature, keep the piping as

straight and short as possible, and slope horizontal runs

so water drains away from pump. The suction line must

be installed at an elevation below the water level when

the tub is fi lled to guarantee fl ooded suction.

ELECTRICAL DATA

Refer to information on motor nameplate for electrical

service data. All motors should have fused disconnect

switch or circuit breaker. Be sure wire size is suffi cient

for HP and distance from power source. Wiring should

be done in accordance with applicable codes by

competent electrician. We recommend the installation of

a ground fault circuit interrupter for maximum safety.

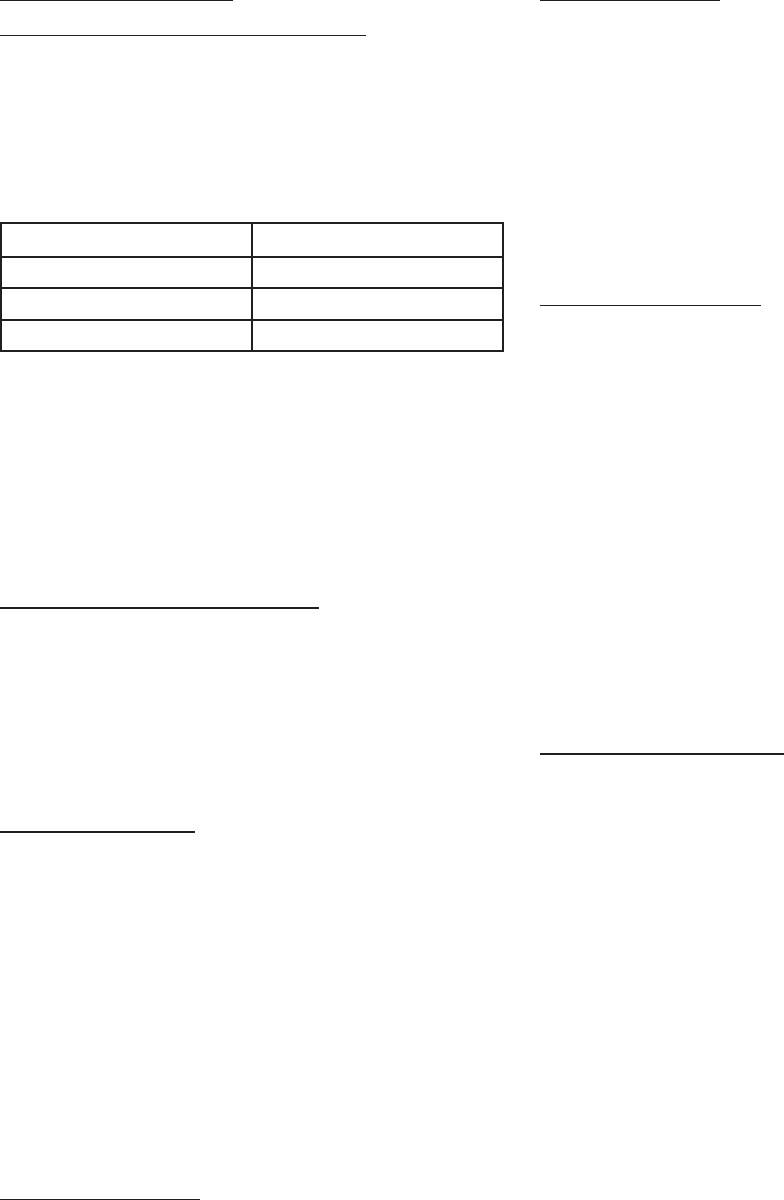

PVC-PVC JOINT PVC-ABS JOINT

Uni-weld Pool-Tite 2000 Uni-weld Pool-Tite 2000

Suregard Flex 20 Suregard Weld-all No. 5

IPS Weld-on 705 IPS Weld-on 794

PUMP START UP

Fill tub to desired level making sure that suction fi ttings

and jets are below water level. Start pump and open all

suction and discharge line valves.

After about 10 minutes of operation, check the return

fi ttings for air bubbles. A continuous fl ow of air indicates

leaks in the suction line. Locate and correct any

leaks immediately.

CAUTION- Do not operate pump with closed suction

or discharge valves.

TWO-SPEED PUMPS

Two-speed models are recommended in a swimming

pool when high speed is needed for maximum fi ltration

at peak periods and whenever turbidity levels are high.

At other times, switch to low speed. For backwashing

and vacuuming, high speed is required.

In spa and hot tubs, use high speed to atain full

performance in the hydro-therapy mode. At other times,

such as fi lter/heat cycle mode, use low speed. Low

speed provides suffi cient fl ow to activate most spa

heaters and provides suffi cient fl ow for fi ltration.

In jetted tubs, use high speed to attain full performance

in the hydro-therapy mode and use low speed for

desired low fl ow conditions.

NOTE: Two-speed pumps must be in high speed

mode to prime.

PUMP MAINTENANCE

1. Motors are self-lubricating-- no lubrication is required.

2. Clean Hair & Lint Strainer if you have a pump with

strainer body.

3. Visually inspect motor for blockage of air vents

on motor shell. Remove any debris after shutting

off breaker.

4. Shaft seals may become worn and must be replaced

if leakage is observed.

SERVICE AND REPAIR PARTS

Refer all service to your local dealer as his knowledge

of your equipment makes him the best qualifi ed source

of information. Order all repair parts through your

dealer. Give the following information when ordering

repair parts.

1. Unit nameplate data

2. Description of part