Product Data Document

1660DS-7c

July 17, 2007 - Page 1

Website: www.EmersonProcess.com/Remote

Remote Automation Solutions

Bristol

®

ControlWave

®

XFC

Gas Flow Computer

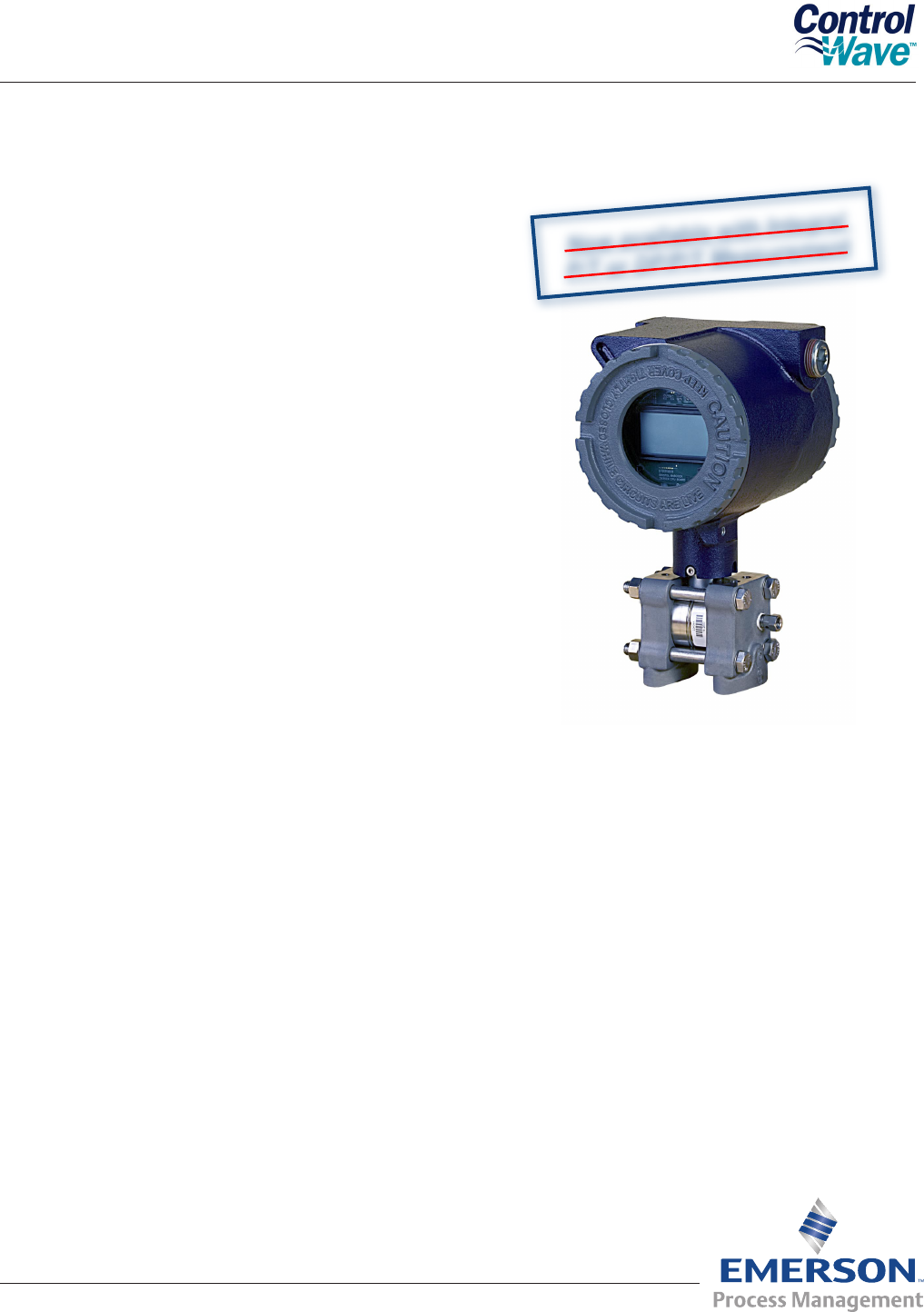

ControlWave XFC comes in a very compact,

explosion-proof package. Smart DP/P sen-

sor assembly is shown in this photo.

Now available with Integral

P/T or DP/P/T Measurement

Bristol® ControlWave® XFC, from Emerson Pro-

cess Management is a cost effective, competitive

solution when requirements call for a chart replace-

ment or ow computer in a compact, explosion-

proof package.

Additionally, ControlWave XFC provides extended

capabilities, such as a second meter run or plunger

lift control, while maintaining the convenience and

simplicity of an integrated, explosion-proof installa-

tion.

ControlWave XFC Overview

Hardware/Packaging Features

Smart, gauge pressure or DP/P sensor

assembly can be removed and replaced,

independently of the "top end" assembly.

Precision RTD interface provides very accurate

process temperature measurement.

Wide, 6.0 to 30.0 Vdc operating input voltage

range works with a broad range of power

sources.

Very low power consumption minimizes costs of

solar/battery power systems.

Three serial communication ports are standard.

Optional I/O includes 2 DI, 2 High-speed

Counter inputs and 4 DO as well as an

additional 3 AI and 1 AO.

Integral 2-line LCD operates in a continuous

cycle mode.

Operating temperature range is -40 to 176ºF

(-40 to 80ºC).

Class I, Division 1 (explosion-proof) and

Division 2 NI approved.

Readily integrates with Emerson’s Bristol 2808

and 3808 MVT low power transmitters for

explosion-proof installations.

•

•

•

•

•

•

•

•

•

•

Firmware/Software Features

ControlWave XFC is pre-programmed to meet

API 21.1 requirements for a two-run metering

station with networking via BSAP or Modbus.

PC web style menu pages are pre-congured

for all user operations.

Using our ControlWave Designer, IEC 61131-3

programming environment, any user or third

party can modify the standard application or

create a completely customized program—and

full support from Emerson is available, every

step of the way.

Additional, standard application programs will

be introduced on a continual basis.

•

•

•

•