292043-UIM-B-0707

8 Unitary Products Group

LOW VOLTAGE CONTROL CONNECTION

The 24 volt power supply is provided by an internally wired low voltage

transformer which is standard on all models. However, if the unit is con-

nected to a 208 volt power supply the low voltage transformer must be

rewired to the 208 volt tap. See the unit wiring label.

Field supplied low voltage wiring can exit the unit on the top right hand

corner or the right hand side panel (see Fig. 5, item K).

Install a 7/8" plastic bushing in the selected hole and keep low voltage

wiring as short as possible inside the control box.

The field wiring is to be connected at the screw terminals of the control

board. Refer to Figure’s 12 and 13.

NOTE: All wiring must comply with local and national electrical code

requirements. Read and heed all unit caution labels.

NOTE: It is possible to vary the amount of electric heat turned on during

the defrost cycle of a heat pump. Standard wiring will only bring on 5

KW of electric heat during defrost see Table 6 and Figures 12 and 13 for

alternate staging.

LINE POWER CONNECTIONS

Power may be brought into the unit through the supply air end of the

unit (top when unit is vertical) or the left side panel. Use the hole appro-

priate to the unit's orientation in each installation to bring conduit from

the disconnect. The power lead conduit should be terminated at the

electrical control box. Refer to Tables 4, 8 & 10 for wire requirements.

Also see Figure 10.

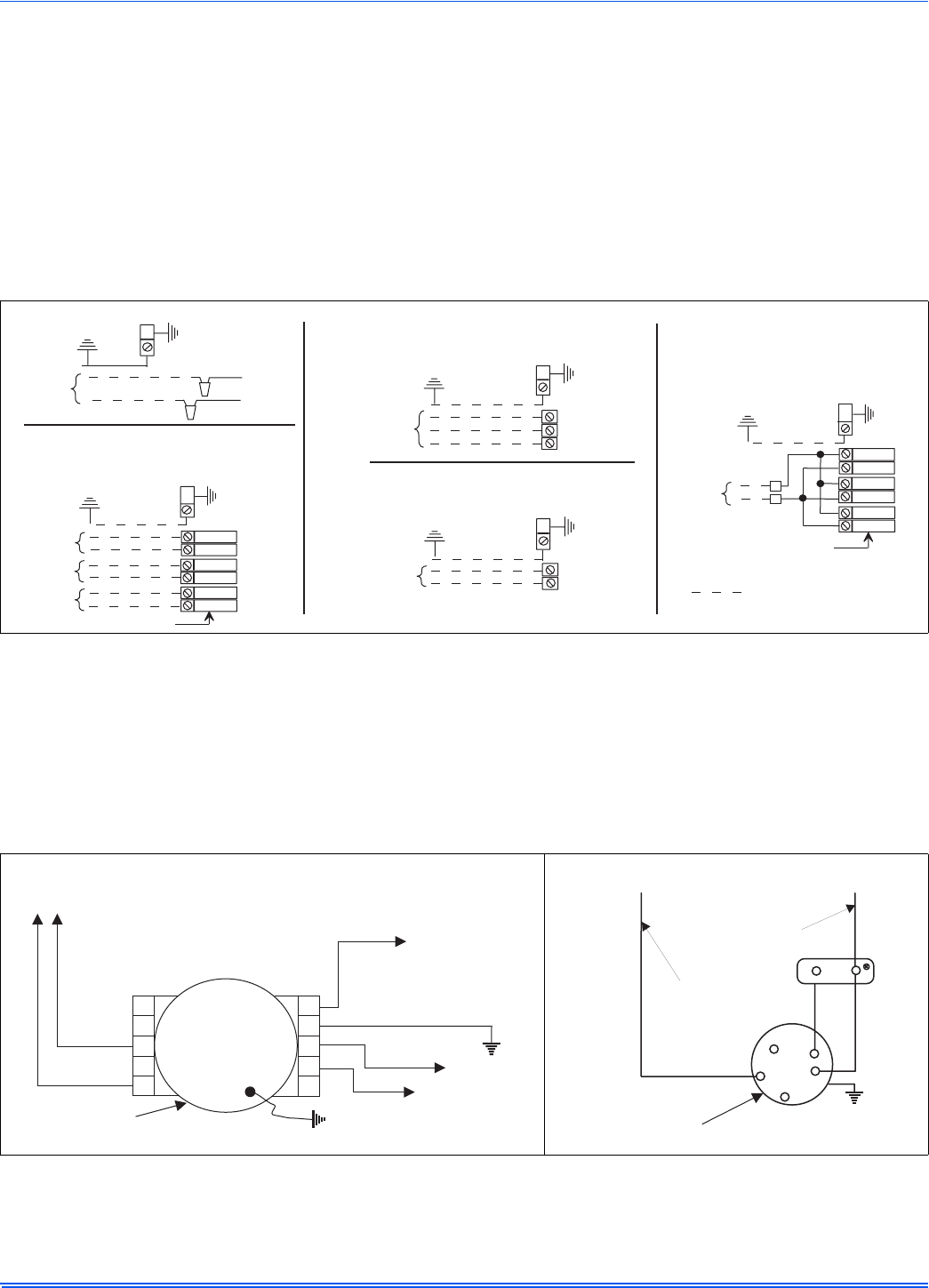

BLOWER SPEED CONNECTIONS

Except for F4FP045, which has a 4-speed motor, and F5FP* which has

a 5-speed high efficiency X-13 motor, all air handlers contain three

speed blower motors which are pre-wired to the control board.

Adjust blower motor speed to provide airflow within the minimum and

maximum limits approved for evaporator coil, electric heat and outdoor

unit. Speed tap adjustments are made at the motor terminal block, See

Figure 11. Airflow data is shown in Tables 6 and 11.

Higher efficiencies will be obtained if the indoor air volume is as high as

possible provided the CFM does not exceed limitations and the sound

level is not objectionable.

Connect motor wires to motor speed tap receptacle for speed desired.

See wiring label for motor wiring details. See Figure 11.

The unit control is designed for the addition of a two speed fan kit. See

accessory kit for details.

FIGURE 10: Line Power Connections

ELECTRIC HEAT

WITHOUT CIRCUIT BREAKER

SINGLE SOURCE (2.5 - 10 KW)

GND. LUG

POWER

SUPPLY

GND.

LUG

ELECTRIC HEAT

WITHOUT CIRCUIT BREAKER

3 PHASE (10 - 15 KW)

GND. LUG

POWER

SUPPLY

GND.

LUG

1 PHASE ELECTRIC HEAT

WITH CIRCUIT BREAKER

AS SHIPPED FROM FACTORY

SINGLE SOURCE

(2.5 - 25 KW) - 25 KW SHOWN

GND. LUG

POWER

SUPPLY

GND.

LUG

1 PHASE ELECTRIC HEAT

WITH CIRCUIT BREAKER

& BREAKER BAR REMOVED

MULTI-SOURCE (15 - 25 KW) - 25 KW SHOWN

GND. LUG

POWER

SUPPLY 1

GND.

LUG

POWER

SUPPLY 2

POWER

SUPPLY 3

TYPICAL WIRING WITHOUT ELECTRIC HEAT

GND. LUG

POWER

SUPPLY

GND.

LUG

POWER WIRING (208/230-1-60)

NOTE: USE ONLY COPPER CONDUCTORS

FIGURE 11: Blower Speed Connections

4-5 TON HIGH EFFICIENCY MOTOR (X-13)

1

2

3

4

5

C

G

L

N

BLK

GRN

YEL

PUR

TO

TRANSFORMER

230V

208 / 230V

FAN MOTOR

TO

RELAY

GRN

BLOWER

YEL

BLU

TO CONTROL

BOARD C

(Common)

FACTORY WIRED TO

TRANSFORMER

FACTORY WIRED TO

FAN MOTOR RELAY

TERMINAL ON

CONTROL BOARD

YEL

PUR

PUR

HIGH

MED

LOW

GND.

230 VOLT

BLOWER MOTOR

1-1/2 TON TO 4 TON STANDARD MOTOR

CAP

BRN