FIRE/EXPLOSION HAZARD. This heater is not intend-

ed for use in hazardous atmospheres where flamma-

ble vapors, gases, liquids or other combustible atmos-

pheres are present as defined in the National

Electrical Code. Failure to comply can result in per-

sonal injury or property damage.

The NWH-JR is a compact water circulation heater ideally

suited for use as an engine coolant water heater and for many other

uses where on-the-spot hot water is required.

The copper-sheathed tubular heating element is centered in a

galvanized iron or brass pipe body. Its screw-plug type mounting

provides easy removal when necessary. The assembly is surround-

ed by insulation and a sheet metal jacket.

An integral 60-180°F range thermostat is provided to control

outlet temperatures. However, this control does not fail-safe.

The system designer is responsible for the safety of

this equipment and should install adequate back-up

controls and safety devices with their electric heating

equipment. Where the consequences of failure could

result in personal injury or property damage, back-up

controls are essential.

(Supersedes PE404-7)

PE404-8

NWH

161-048467-001

APRIL, 2005

4

and

Installation, Operation

RENEWAL PARTS IDENTIFICATION

NWH-JR Circulation Heater For Water Heating

© 2010 Chromalox, Inc.

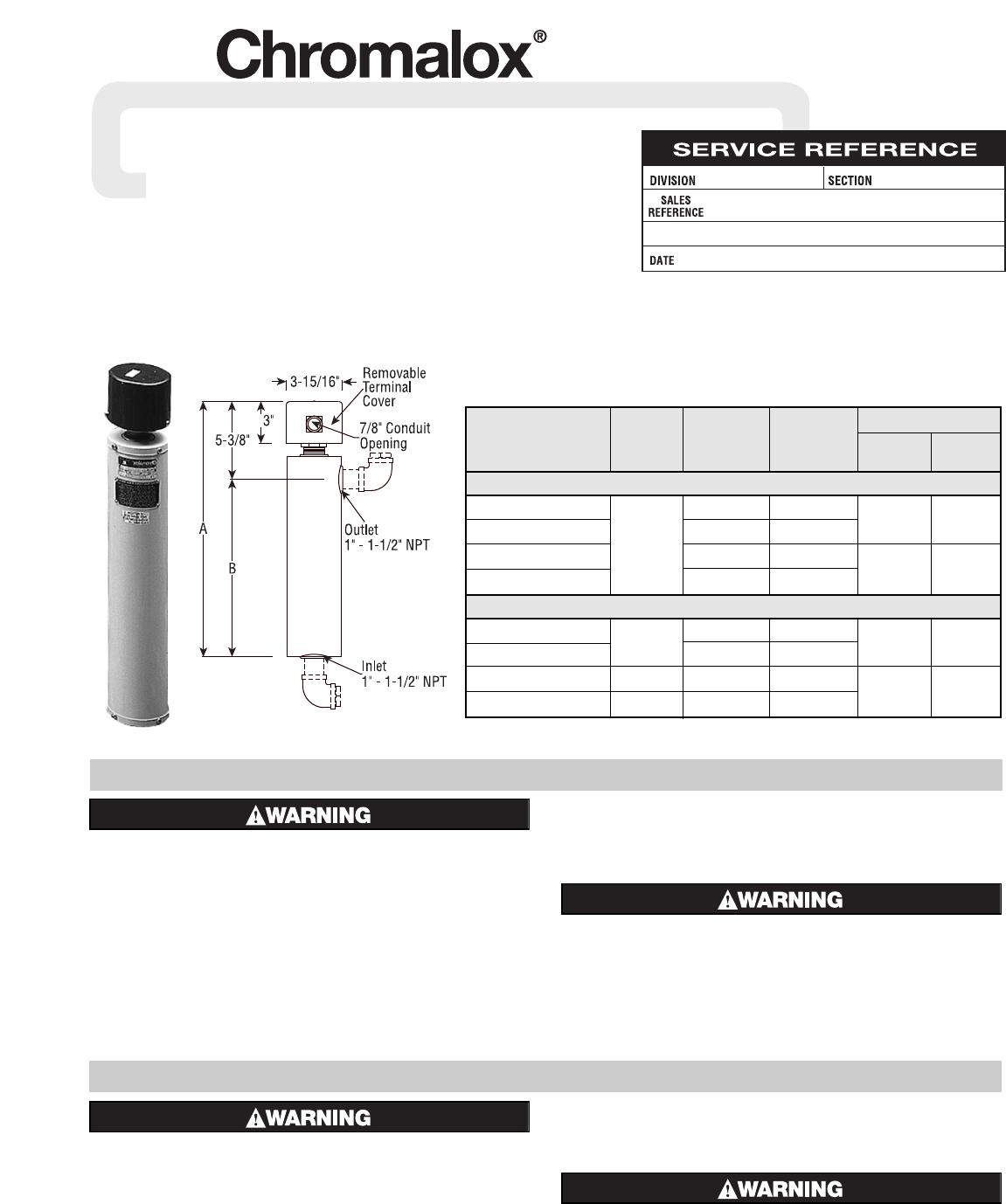

Dimensions (In.)

Watt

Model Volts kW Density A B

Galvanized Iron Construction

NWHJRG-01-01P5-E1 120 1.5 82

18 12-3/8

NWHJRG-01-002P-E1

or

283

NWHJRG-01-02P5-E1 2.5 78

NWHJRG-01-003P-E1 240 3 78

22 16-3/8

Brass Construction

NWHJRB-01-01P5-E1 120 or 1.5 82

18 12-3/8

NWHJRB-01-002P-E1 240 2 83

NWHJRB-01-02P5-E1 240 2.5 78

NWHJRB-01-003P-E1 240 3 78

22 16-3/8

Specifications – Table A

GENERAL

INSTALLATION

ELECTRIC SHOCK HAZARD. Disconnect all power

before installing or servicing heater. Failure to do so

could result in personal injury or property damage.

Heater must be installed by a qualified person in accor-

dance with the National Electrical Code, NFPA 70

1. The NWH-JR circulation heater should be mounted vertically with

the terminal enclosure at the top. No additional support other than

the connecting pipes is needed.

2. Make piping connections to either new or existing plumbing at the

1 x 11-1/2” NPT threaded inlet and outlet as shown above.

3. If foreign material is to be carried by the liquid flow, install suit-

able filters in the inlet pipe to the heater.

4. Provide adequate space at terminal end to permit withdrawal of the

heater from chamber should servicing be required.

FIRE HAZARD. Since heaters are capable of develop-

ing high temperatures, extreme care should be taken

to:

A. Provide a minimum of 6” spacing from chamber and related

piping to nearest combustible material.

B. Do not heat combustible materials.

Figure 1