OPTIONAL EQUIPMENT FOR STEAM BOILERS

IF A CONTROLLER SEEMS TO OPERATE IMPROPERLY

If the controller is suspected of operating improperly, it may be

further checked as follows:

1. Leave the controller installed where it is, but disconnect all power

to the boiler.

2. Loosen the cover screw below the main scaleplate and remove the

cover.

3. Disconnect the wires from the controller.

4. Connect an ohmmeter between controller terminals B and W to

measure the resistance of the potentiometer in the controller. The

ohmmeter should read about 135 ohms on an L91B.

5. Connect the ohmmeter between controller terminals W and R and

raise the set point of the controller above the actual pressure being

measured. The ohmmeter should read the full value of the poten-

tiometer measured in step 4 (135 ohms for an L91B).

6. Slowly lower the set point of the controller while observing the

ohmmeter reading. The resistance should drop to zero at some set

point below the actual pressure.

7. An approximation of the proportioning range can be made by

observing the change in set point required for a resistance change

from zero to full value.

8. When the controller is operating properly, reconnect the wires,

replace the cover, tighten the cover screw, and reset the controller

to the desired value.

9. Reconnect power to the controlled motor.

BOILER SEQUENCER (5 STEP) MOTOR DRIVEN

RECYCLE FEATURE

The step control is designed to drop out all contactors when con-

trol circuit is interrupted. On resumption of power, the camshaft

rotates to the counterclockwise (ccw) limit, opening all the load

switches. The recycle relay then energizes, pulling in the load con-

tact, and finally the camshaft rotates clockwise (cw) to the position

called for by the pressure controller energizing, in sequence, the

required load stages.

TESTING OPERATION OF SEQUENCER

1. With boiler off, remove wiring from pressure control on

sequencer low voltage terminal board.

2. Turn on boiler to supply the voltage to the sequencer. Short ter-

minal R and B for counterclockwise rotation and terminal R and

W for clockwise rotation.

3. If sequencer operates under this test procedure, but when rewired

to pressure controller and does not function, check pressure con-

trol. Note that wiring is W-B and B-W-R-R between sequencer

and pressure controller

BOILER SEQUENCE — SOLID STATE

Solid State Progressive Sequencer

The solid state progressive sequencer provides accurate elec-

tronic control of multi-stage loads of the type used in Chromalox

steam boilers. It features progressive sequencing (first on-first off)

which equalizes the operating time of each load. This control gives

visual indication of each energized stage by means of integral solid

state light emitting diodes. In the event of power interruption, all

heating elements are immediately de-energized for safety. When

power resumes, the control will restage the loads one at a time.

The solid state sequencer operates on 120V AC/60 Hz and each

output is relay switched with a load rating of 125 VA at 120V AC.

The input to the sequencer is a 0-135 OHM potentiometer sup-

plied on the operating pressure control. The sequencer has a sensi-

tivity control which is adjustable from min. to max. This sensitivity

control defines the amount of resistance (pressure) deviation

allowed before adding or subtracting a load. Potentiometer resis-

tance should decrease with increasing pressure. Connections are

made to red and white terminals of proportional pressure control.

See Wiring Diagram 337-300164-452 for Boiler With Solid State

Sequencer.

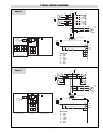

Main Scale

Adjusting

Screw

Proportioning Range

Adjusting Screw

R

W

B

Main Scale

Setting

Indicator

Set Point

Increase

R

W

B

Ohmmeter

Increases to

135 Ohms

Terminals are not Labeled, but Screw-Heads are

Color Coded Red (R), White (W) and Blue (B).

15

Solid State Sequencer

Sequencer (5-Step)