19

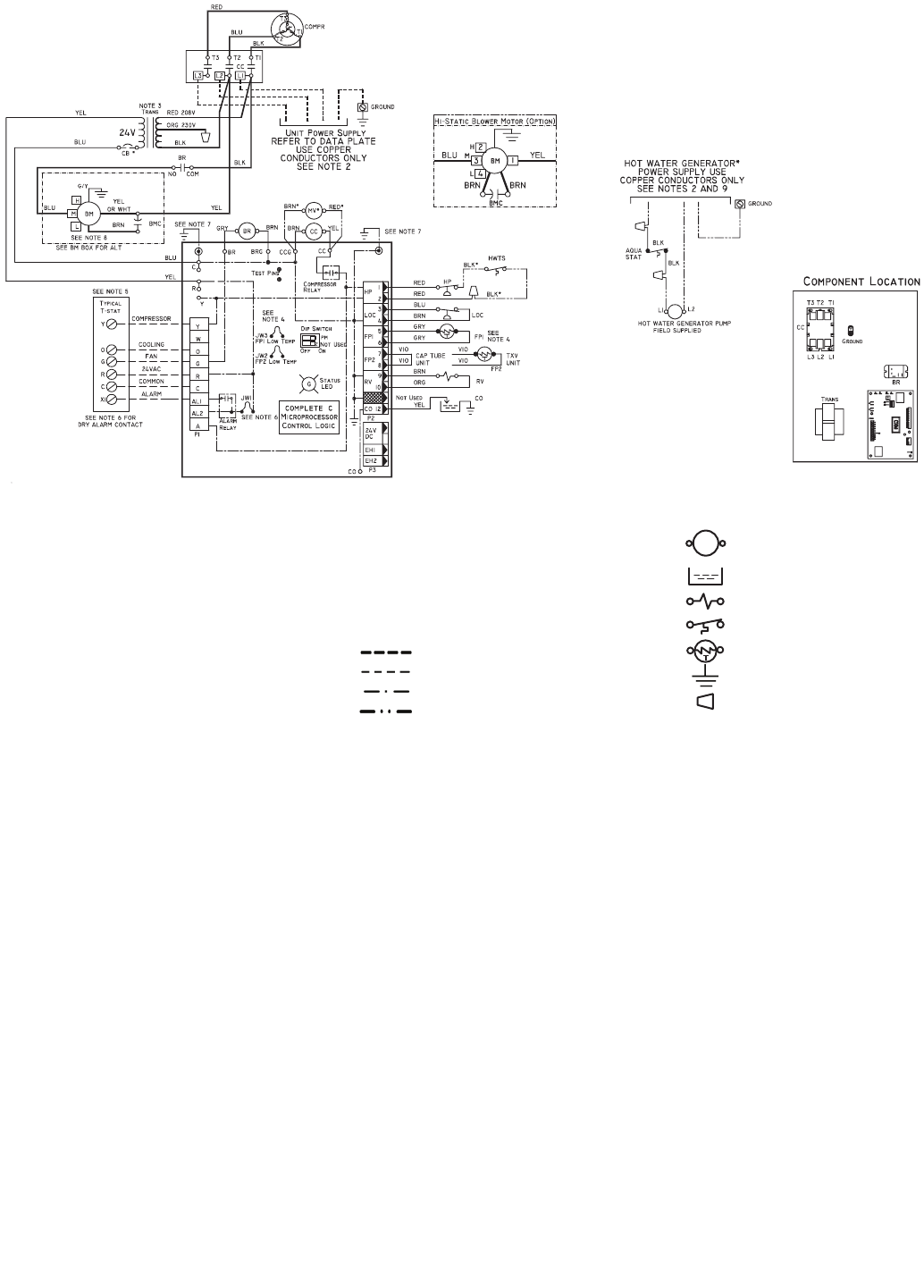

*Optional wiring.

AL — Alarm Relay Contacts

BM — Blower Motor

BMC — Blower Motor Capacitor

BR — Blower Relay

CB — Circuit Breaker

CC — Compressor Contactor

CO — Sensor, Condensate Overflow

COMPR — Compressor

FP1 — Sensor, Water Coil Freeze Protection

FP2 — Sensor, Air Coil Freeze Protection

HP — High-Pressure Switch

HWTS — High (Leaving) Water Temperature

Switch

JW1 — Jumper, Alarm

NOTES:

1. Compressor and blower motor thermally protected internally.

2. All wiring to the unit must comply with NEC and local codes.

3. Transformer is wired to 265 v (BRN) lead for 265/1/60 units, or

208 v (RED) lead for 208/1/60. For 230/1/60 switch RED and

ORG leads at L1 and insulate RED lead. Transformer is energy

limiting or may have circuit breaker.

4. FP1 thermistor provides freeze protection for water. When using

antifreeze solutions, cut JW3 jumper.

5. Typical Aquazone thermostat wiring shown. Refer to thermostat

installation instructions for wiring to the unit. Thermostat wiring

must be Class 1 and voltage rating equal to or greater than unit

supply voltage.

Fig. 19 — Typical Aquazone™ Complete C Control Wiring

LEGEND

LOC — Loss of Charge Pressure Switch

MV — Motorized Valve

NEC — National Electrical Code

P1 — Field Wiring Terminal Block

PM — Performance Monitor

RV — Reversing Valve Coil

TRANS — Transformer

TXV — Thermostatic Expansion Valve

Field Line Voltage Wiring

Field Low Voltage Wiring

Printed Circuit Trace

Optional Wiring

Relay/Contactor Coil

Condensate Pan

Solenoid Coil

Temperature Switch

Thermistor

Ground

Wire Nut

6. 24-v alarm signal shown. For dry alarm contact, cut JW1 jumper

and dry contact will be available between AL1 and AL2.

7. Transformer secondary ground via control board standoffs and

screws to control box. (Ground available from top two standoffs

as shown.)

8. For high or low speed remove BLU wire from BR ‘NO’

and replace with BLK or RED wire respectively. Tape off unused

terminal.

9. Both DIP switches need to be in the ON position.

a50-8160