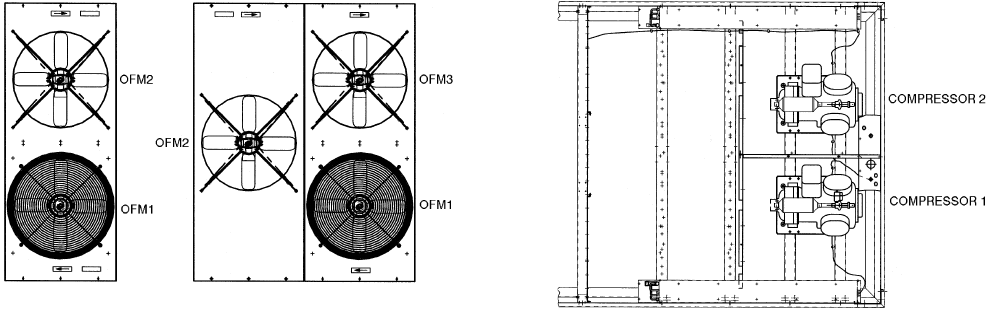

SIZE 044 UNITS — These units have 2 compressors and 1

unloader on compressor no. 1. See Fig. 42 for compressor

and condenser fan motor locations. The unit operating se-

quence is as follows:

Stage 1 Relays K1 and K3 are energized. Compressor

no. 1 starts with the unloader energized. Com-

pressor no. 1 is running at

1

⁄

2

capacity. The crank-

case heater on compressor no. 1 has been deen-

ergized, and the first stage condenser fan has been

energized. Outdoor (condenser) fan motor no. 1

(OFM1) has started.

Stage 2 Relay K1 is energized. Compressor no. 1 is fully

loaded.

Stage 3 Relays K1, K3, and K5 are energized. Compres-

sor no. 1 is running at

1

⁄

2

capacity, and compres-

sor no. 2 is running at full capacity. The crankcase

heater for compressor no. 2 is deenergized. The

second stage condenser fan has been energized.

Both OFM1 and OFM3 are operating.

Stage 4 Relays K1 and K5 are energized. Both compres-

sors are running fully loaded.

Size 044 units have one fan that can be controlled by the

processor. The other 2 are controlled by the compressors.

The OFM1 is energized by compressor no. 1, and OFM3 is

energized by compressor no. 2. The OFM2 is cycled by the

processor based on input from either circuit (thermistors T3

and T4).

SIZE 104 UNITS — These units have 4 compressors and

1 unloader on compressor no. 1. See Fig. 43 for compressor

and condenser fan motor locations. The unit operating se-

quence is as follows:

Stage 1 Relays K1 and K3 are energized. Compressor

no. 1 starts with unloader energized. Compressor

no. 1 runs at

2

⁄

3

capacity. The crankcase heater for

this compressor has been deenergized, and first stage

of condenser fans has been energized. Outdoor (con-

denser) fan motor no. 1 (OFM1) and oudoor fan

motor no. 3 (OFM3) have started.

Stage 2 Relay K1 is energized. Compressor no. 1 is fully

loaded.

Stage 3 Relays K1, K3, and K5 are energized. Compres-

sor no. 1 runs at

2

⁄

3

capacity and compressor

no. 2 is running at full capacity. The crankcase

heater for compressor no. 2 is deenergized. The

first stae of condenser fans on circuit 2 has been

energized. Fans OFM1, OFM2, OFM3, and OFM4

are operating.

Stage 4 Relays K1 and K5 are energized. Both compres-

sors no. 1 and no. 2 are running fully loaded.

Stage 5 Relays K1, K3, K5, and K5 are energized. Com-

pressor no. 1 runs at

2

⁄

3

capacity and compressors

no. 2 and no. 4 are running at full capacity. The

crankcase heater on compressor no. 4 is deener-

gized. Fans OFM1, OFM2, OFM3, and OFM4 are

operating.

Stage 6 Relays K1, K5, and K6 are energized. Compres-

sors no. 1, no. 2, and no. 4 are running fully loaded.

Stage 7 Relays K1, K2, K3, K5, and K6 are energized.

Compressor no. 1 runs at

2

⁄

3

capacity and com-

pressors no. 2, no. 3, and no. 4 are running at full

capacity. Fans OFM1, OFM2, OFM3, and OFM4

are operating. Crankcase heater for compressor

no. 3 is deenergized.

Stage 8 Relays K1, K2, K5, and K6 are energized. Com-

pressors no. 1, no. 2, no. 3, and no. 4 are running

fully loaded.

On Size 104 units, the first 4 condenser fans energize with

the compressors; circuit no. 1 compressors control OFM1

and OFM3, and circuit no. 2 compressors control OFM2 and

OFM4. The OFM5 and OFM6 are staged by the micro-

processor based on condensing temperature input from

either circuit’s T3 or T4 thermistor.

Head Pressure Control — All units have as standard

a basic head pressure control function which allows the units

to operate in cooling down to 45 F. If cooling is required at

outdoor ambient temperatures lower than 45 F, refer to ac-

cessory head pressure control literature for details.

Head pressure control is handled by the processor. The

processor attempts to maintain the head pressure by cycling

the condenser-fan motors. No condenser fans will be run-

ning without a call for mechanical cooling. Thermistors T3

and T4 provide the condensing temperature information to

the processor. These VAV rooftop units have dual refrigera-

tion circuits, and the higher circuit temperature will govern

unit operation. If the condensing temperature is above

133 F (236 psig), a condenser fan stage will be added. If the

condensing temperature is 78 F (142 psig) or less, the num-

ber of condenser fans operating will be decreased.After each

fan stage, the processor will wait one minute for the head

pressures to stabilize before changing again, unless ther-

mistor T3 or T4 senses a temperature greater than 125 F

(278 psig), in which case all condenser fans are started.

During start-up, if the outdoor ambient is above 70 F (as

sensed by thermistor T3 or T4), the first-stage, processor-

controlled fans are turned on to prevent excessive discharge

pressures.

034 AND 038 UNITS 044 AND 048 UNITS

LEGEND

OFM — Outdoor (Condenser) Fan Motor

Fig. 42 — Component Arrangement, 034-048 Units

36