9

Preparation

— The unit should be on the ground in a well lit

area. Hung units should be taken down to ground level before

converting.

Side to Back Discharge Conversion

1. Remove screws to free the top and discharge panels. Set

screws aside for later use. See Fig. 7.

2. Remove the access panel and set aside.

3. Lift the discharge panel from side of unit and rotate it to

back using care not to damage blower wiring.

4. Check blower wire routing and connections for undue

tension or contact with sheet metal edges. Re-route if

necessary.

5. Check refrigerant tubing for contact with other compo-

nents. Adjust if necessary.

6. Reinstall top panel using screws set aside in Step 1.

NOTE: Location for some screws at bottom of discharge

panel may have to be changed.

7. Manually spin fan wheel to check for obstructions.

Adjust for any obstruction found.

8. Replace access panel.

Back to Side Discharge Conversion

— Follow instructions

above for Side to Back Discharge Conversion, noting the

panels would be reversed.

Step 4 — Mount the Unit

HORIZONTAL UNIT (50PSH) — Horizontal units should

be mounted using the factory-installed hangers. Proper attach-

ment of hanging rods to building structure is critical for safety.

See Fig. 1. Rod attachments must be able to support the weight

of the unit. See Table 1 for unit operating weights.

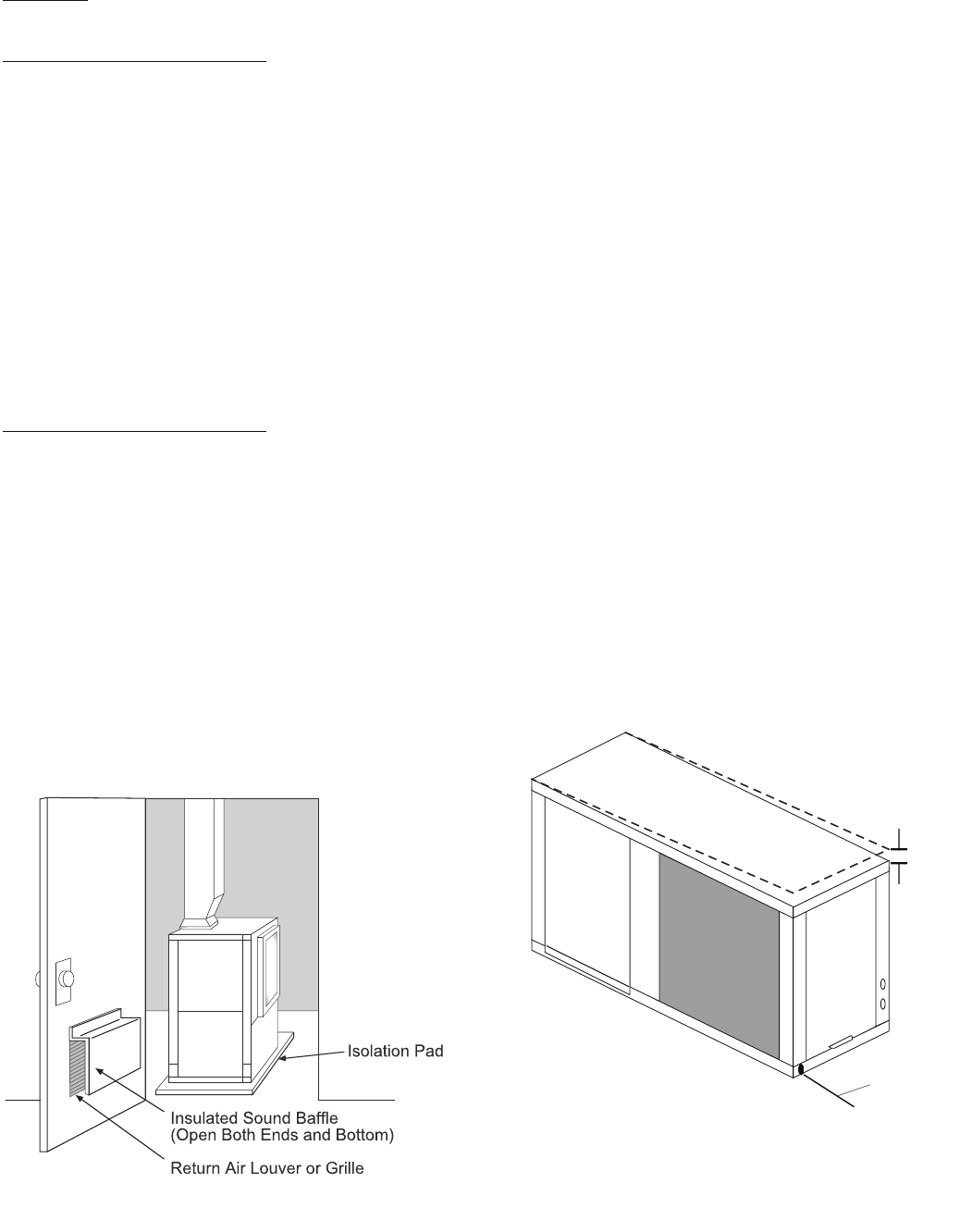

VERTICAL UNITS (50PSV, PSD) — Vertical and downflow

units are available in left or right return air configurations. See

Fig. 3 and 4. Mount the unit (except 50PSD) on a vibration

absorption pad slightly larger than the entire base to minimize

vibration transmission. It is not necessary to mount the unit on

the floor. See Fig. 9.

NOTE: Some codes require the use of a secondary drain pan

under vertical units. Check local codes for more information.

Step 5 — Check Duct System — Size the duct sys-

tem to handle the design airflow quietly.

NOTE: Depending on the unit, the fan wheel may have a ship-

ping support installed at the factory. This must be removed

before operating unit.

SOUND ATTENUATION — To eliminate the transfer of

vibration to the duct system, a flexible connector is recom-

mended for both discharge and return air duct connections on

metal duct systems. The supply and return plenums should in-

clude internal duct liner of fiberglass or be made of duct board

construction to maximize sound attenuation of the blower.

Installing the WSHP unit to uninsulated ductwork in an uncon-

ditioned space is not recommended since it will sweat and

adversely affect the unit’s performance.

To reduce air noise, at least one 90-degree elbow could be

included in the supply and return air ducts, provided system

performance is not adversely impacted. The blower speed can

also be changed in the field to reduce air noise or excessive air-

flow, provided system performance is not adversely impacted.

EXISTING DUCT SYSTEM — If the unit is connected to

existing ductwork, consider the following:

• Verify that the existing ducts have the proper capacity to

handle the unit airflow. If the ductwork is too small, install

larger ductwork.

• Check existing ductwork for leaks and repair as necessary.

NOTE: Local codes may require ventilation air to enter the

space for proper indoor air quality. Hard-duct ventilation

may be required for the ventilating air supply. If hard

ducted ventilation is not required, be sure that a proper air

path is provided for ventilation air to unit to meet ventila-

tion requirement of the space.

Step 6 — Install Condensate Drain

HORIZONTAL UNIT (50PSH) — Slope the unit toward the

drain at

1

/

4

in. See Fig. 10. If it is not possible to meet the re-

quired pitch, install a condensate at the unit to pump conden-

sate to building drain.

Horizontal units are not internally trapped, therefore an ex-

ternal trap is necessary. Install each unit with its own individual

trap and means to flush or blow out the condensate drain line.

Do not install units with a common trap or vent. See Fig. 11 for

typical condensate connections.

NOTE: Never use a pipe size smaller than the connection.

1/4Ó Pitch for

Drainage

Drain Connection

Pitch Toward

Drain

Fig. 10 — Horizontal Unit Pitch

A50-6260

Fig. 9 — 50PSV Units Mounted With

Vibration Absorption Pad

A50-7731ef