48

2. Fan status switch input should close. Note the unit will

not start unless the fan status input is closed.

3. Close Y1 input unit will stage up to 50 % capacity with

1 minute between stages.

4. Close Y2 input the unit will stage up to 100% capacity

with 1 minute between stages.

CV APPLICATION — C.TYP = 3

1. Start indoor fan motor.

2. Fan status switch input should close. Note the unit will

not start unless the fan status input is closed.

3. Close Y1 input unit. The control will control supply-air

temperature to CSP1 and stage capacity as required.

4. Close Y2 input. The unit will control supply-air tempera-

ture to CSP2 and stage capacity as required.

CV APPLICATION — C.TYP = 5

1. Start indoor fan motor.

2. Fan status switch input should close. Note the unit will

not start unless the fan status input is closed.

3. The control will use space temperature (Tempe ratures

SPT) vs space temperature set point (Set Point

COOL SPS.P) to decide to whether to control supply-

air temperature to CSP1 or CSP2, and will stage capacity

as required.

% CAPACITY INPUT — C.TYP = 7

1. Start indoor fan motor.

2. Fan status switch input should close. Note the unit will

not start unless the fan status input is closed.

3. The control will adjust unit capacity based on the 4 to

20mA Cool mA (INPUTS 4-20 CL.MA).

4. Actual capacity and desired capacity may be different due

to unit diagnostics.

OPERATION

Operating Limitations

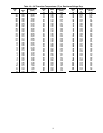

AMBIENT LMITATIONS — See Table 16 for ambient

limitations.

Table 16 — 38AP Unit Ambient Limitations

Single Circuit

Dual Circuit

* Factory-installed option or field-installed accessory.

†Operation above listed temperature depends on the saturated suction tem-

perature the unit is operating at. Refer to ECAT for exact limitations.

VOLTAGE (ALL UNITS)

Main Power Supply

— Minimum and maximum acceptable

supply voltages are listed in the Installation Instructions.

Unbalanced 3-Phase Supply Voltage — Never operate a motor

where a phase imbalance between phases is greater than 2%.

To determine percent voltage imbalance:

The maximum voltage deviation is the largest difference

between a voltage measurement across 2 legs and the average

across all 3 legs.

Example: Supply voltage is 240-3-60.

AB = 243 v

BC = 236 v

AC = 238 v

1. Determine average voltage:

2. Determine maximum deviation from average voltage:

(AB) 243 – 239 = 4 v

(BC) 239 – 236 = 3 v

(AC) 239 – 238 = 1 v

Maximum deviation is 4 v.

3. Determine percent voltage imbalance:

This voltage imbalance is satisfactory as it is below the

maximum allowable of 2%.

Control Circuit Power

— Power for the control circuit is

supplied from the main incoming power through a factory-

installed control power transformer (TRAN1) for all models.

Field wiring connections are made to LVT terminal board.

Operation Sequence — During unit off cycle, if power

is maintained to the unit and the EMERGENCY ON/OFF

switch is left in the OFF position, the compressor crankcase

heaters will be energized.

The unit is started by putting the ENABLE/OFF/REMOTE

CONTACT switch in the ENABLE or REMOTE CONTACT

position. When the unit receives a call to run (either from the

internal control, or CCN network command or remote contact

closure), the unit stages up in capacity to maintain either supply

air temperature or space temperature. The first compressor

starts 1

1

/

2

to 3 minutes after the call for cooling.

The lead circuit can be specifically designated on all models

or selected based on compressor run hours and starts depend-

ing on field configuration. The unit control will override this

selection under certain starting conditions to properly maintain

oil return to the compressors. The MBB controls fan stages to

maintain the head pressure set point and will automatically ad-

just unit capacity as required to keep compressors from operat-

ing outside of the specified envelope. There are no pumpout or

pumpdown sequences on these units.

The liquid line solenoid valve is energized anytime a com-

pressor is operating in the circuit and also when the circuit is

OFF and the OAT is less than the SST. The liquid line solenoid

valve is de-energized 5 seconds after the circuit stops and also

when the circuit is OFF and the OAT is greater than the SST

plus 2° F. Each circuit operates independently.

38APS

UNIT

SIZE

MINIMUM LOW

AMBIENT

(Standard Unit)

MINIMUM LOW AMBIENT

MOTORMASTER

®

CONTROL*

MAXIMUM

AMBIENT†

025-050 45 F (7.2 C) 20 F ( 28.9 C) 122 F (50 C)

38APD

UNIT

SIZE

MINIMUM LOW

AMBIENT

(Standard Unit)

MINIMUM LOW AMBIENT

MOTORMASTER

CONTROL*

MAXIMUM

AMBIENT†

025-040 32 F (0 C) 20 F ( 28.9 C) 122 F (50 C)

050-060 25 F ( 3.9 C) 20 F ( 28.9 C) 122 F (50 C)

070-100 32 F (0 C) 20 F( 28.9 C) 122 F (50 C)

% Voltage Imbalance = 100 x

max voltage deviation

from avg voltage

average voltage

–

–

–

–

–

–

–

–

–

Average voltage =

243 + 236 + 238

3

=

717

3

= 239

% Voltage Imbalance = 100 x

4

239

= 1.7%

IMPORTANT: If the supply voltage phase imbalance is

more than 2%, contact your local electric utility company

immediately. Do not operate unit until imbalance condition

is corrected.